Manganese ferroalloy finery vehicle type folding smoke helmet

A ferroalloy, refining furnace technology, applied in the direction of removing smoke and dust, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of air pollution, affecting the operating environment, etc., and achieve the effect of sturdy use, stable movement, and reduced air volume for processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

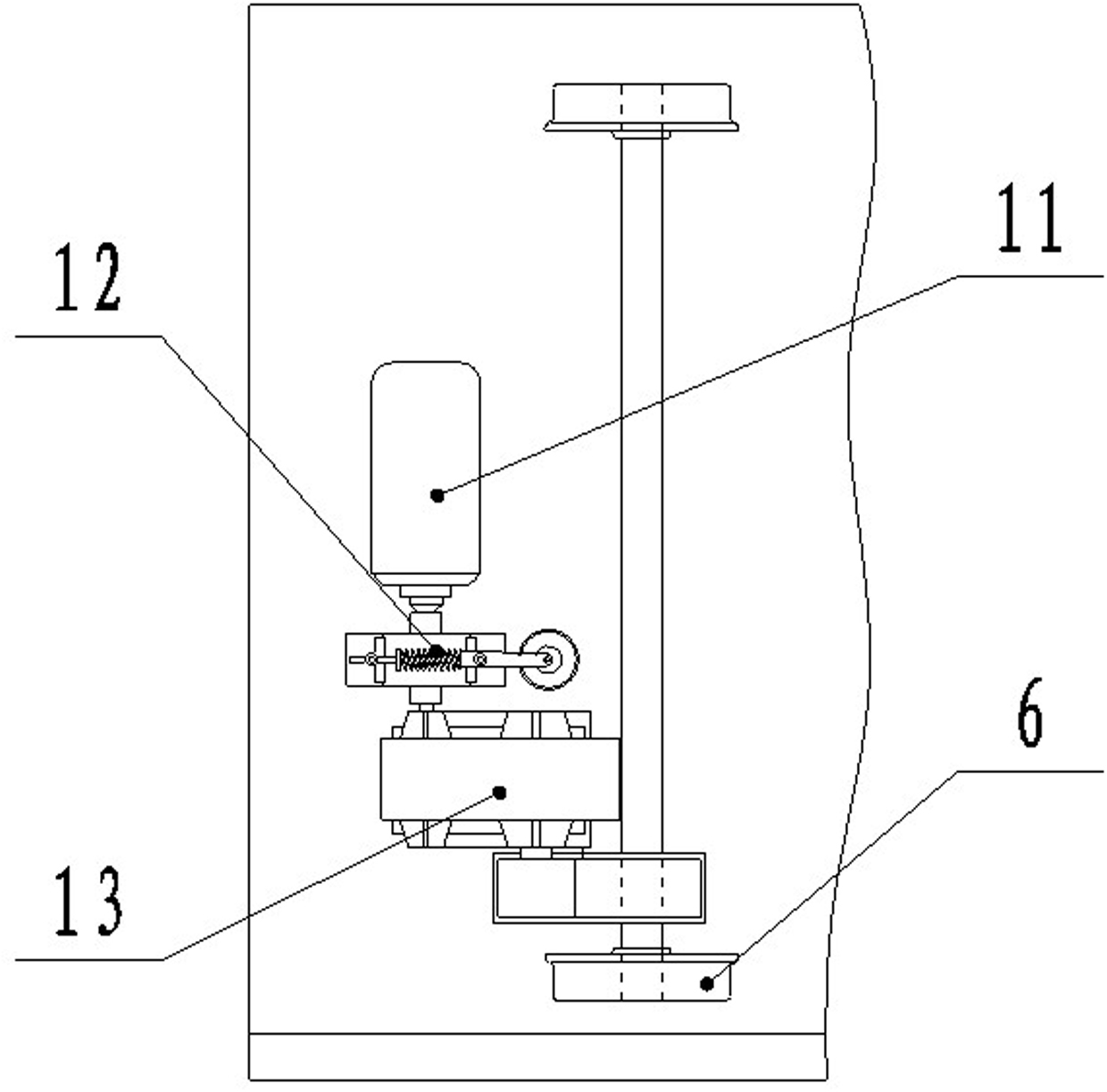

[0011] Manganese-based ferroalloy refining furnace car-type folding hood, including a telescopic platform 2 located above the iron tank 1, the telescopic platform 2 is composed of a front hood plate 4 with a smoke inlet 3 at the front and the front end is inserted into the front hood plate 4 The rear cavity is composed of a rear hood plate 5 that moves forward and backward in the cavity. The left and right sides of the front hood plate 4 and the rear hood plate 5 are equipped with walking wheels 6 supported on the front guide rail and the rear guide rail. , the front and rear ends of the rear guide rail are all provided with stoppers, the walking wheels 6 of the front smoke hood plate 4 are provided with a power drive mechanism, and the front smoke hood plate 4 around the smoke inlet 3 is fixed with a gas collection cover 7, and the gas collection A docking plate 8 is arranged above the cover 7, and the butt plate 8 is provided with elongated holes in the front and rear directi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com