Claw pressing type connecting piece of stainless steel pipeline

A technology of pipe joints and stainless steel, applied in the direction of pipe/pipe joint/pipe fitting, pipe element, sealing surface connection, etc., can solve the problems of increasing installation cost, increasing labor input, troublesome installation and maintenance, etc., to avoid secondary construction , Shorten the construction time, the effect of firm connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

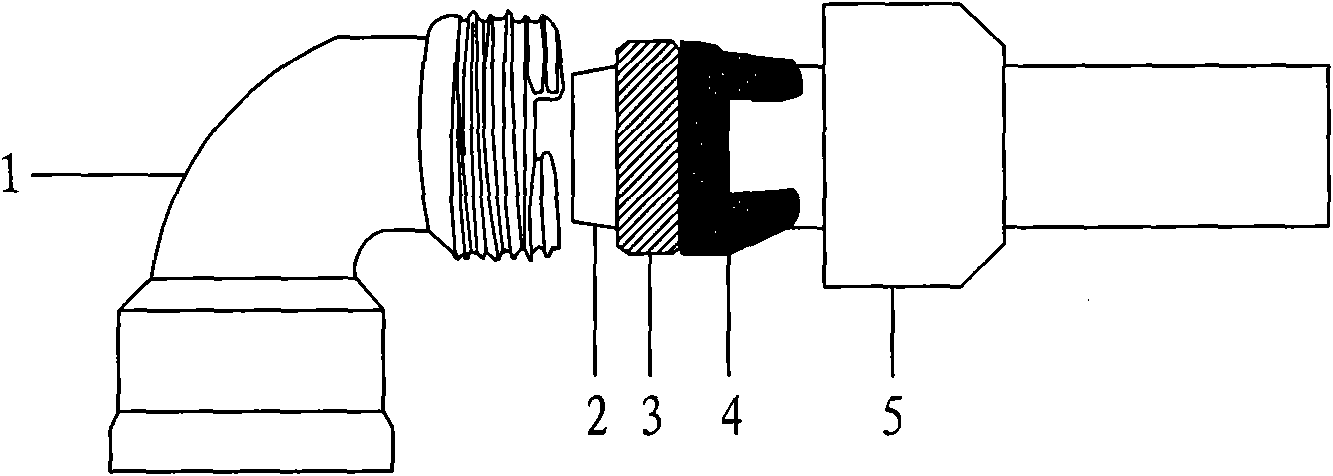

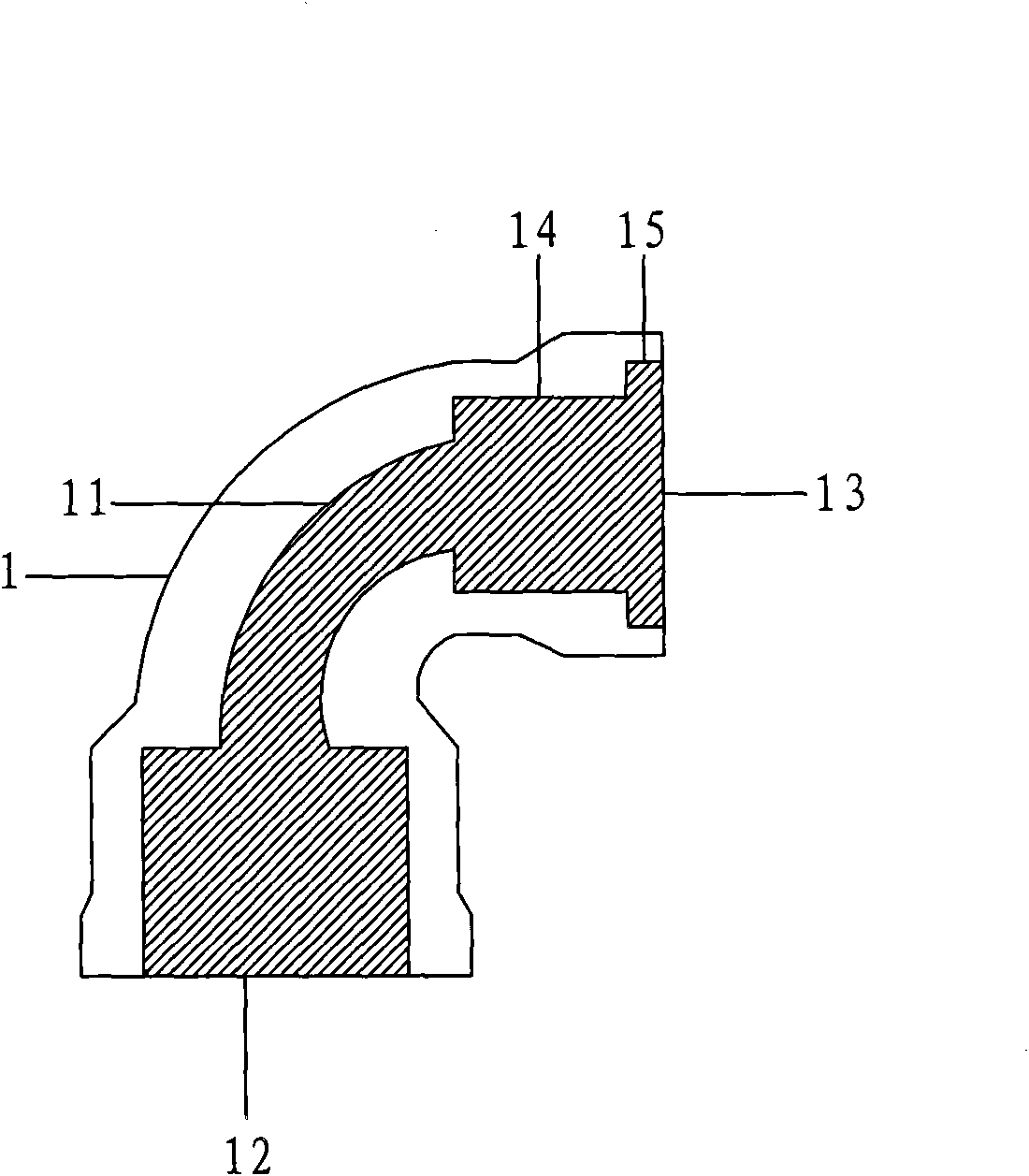

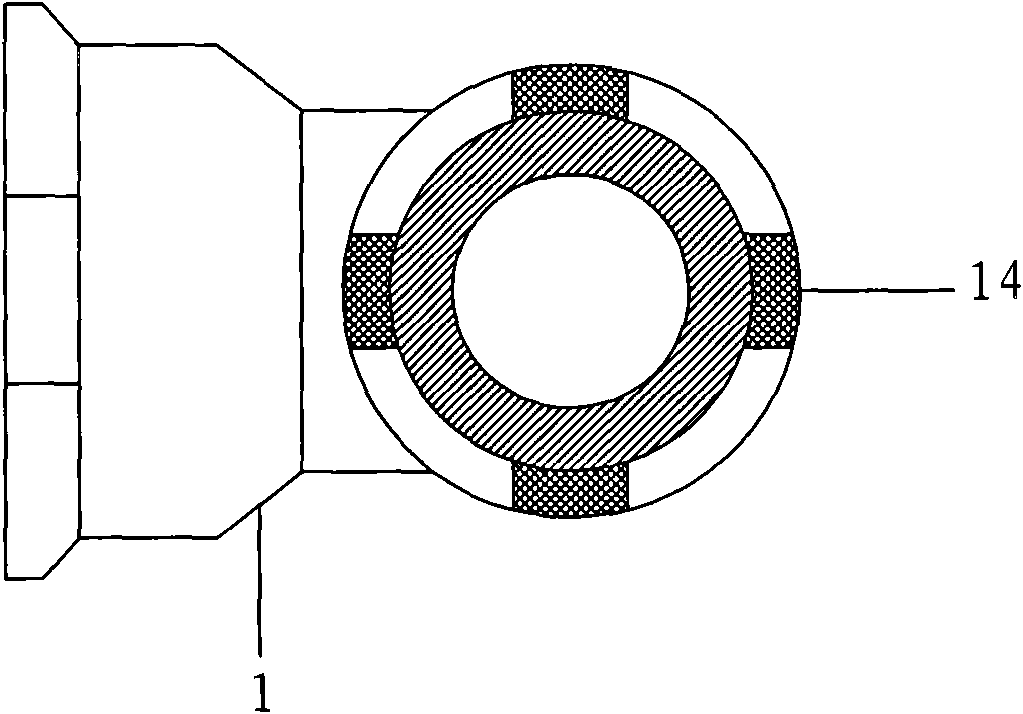

[0022] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , a claw pressure stainless steel pipe connector, including an elbow 1, the elbow 1 can be T-shaped, in-line or other suitable shape, the inside of the elbow 1 is provided with a through hole 11 and the left and right Two ends are provided with left and right interface 12,13, and described through hole 11 communicates with left and right interface 12,13, and the inner circumference of described left interface 12 is provided with screw thread, and connecting pipe 2 is installed in the right interface 13, and connecting pipe The outer wall of 2 is sequentially sleeved with sealing ring 3, fixed ring 4, and nut 5, and said nut 5 is threadedly connected with right interface 13. According to actual needs, when the thread of nut 5 is arranged on the inner wall, the right interface 13 Thread is then located on the outer wall; when ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com