Pin-implanting punching machine for false teeth

A technology of dentures and nails, which is applied in dentistry, dental prosthetics, dental tools, etc., can solve the problems of not having a dust exhaust system, affecting the health of employees, and large dust, so as to improve brightness, use safety, and reduce dust. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

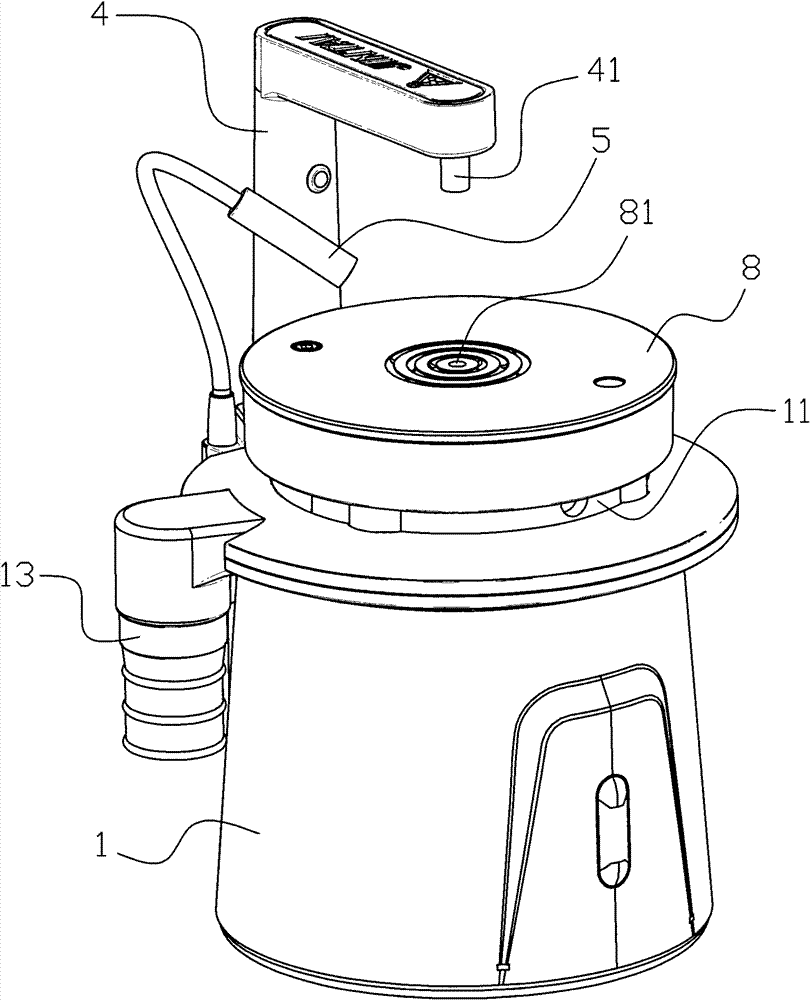

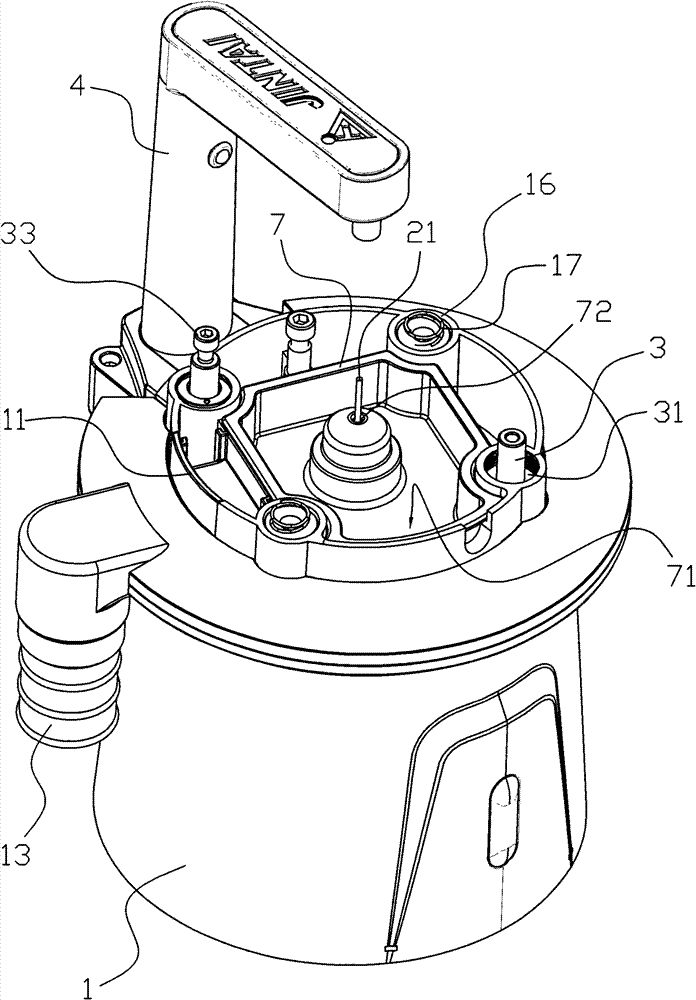

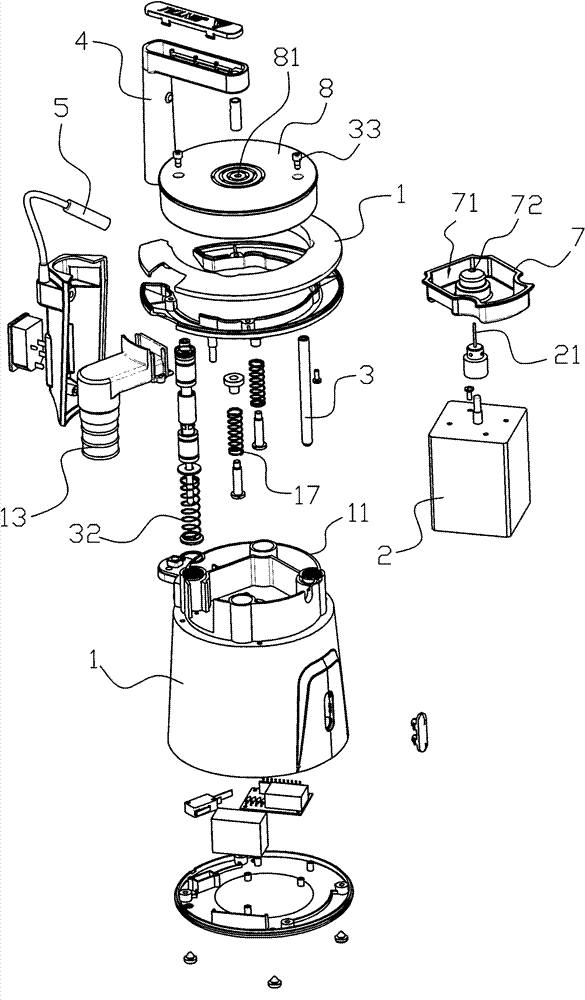

[0024] Such as Figure 1 to Figure 7 As shown, the seed nail punching machine for dentures in this embodiment includes a frame 1, a motor 2, a denture positioning plate 8, and a drill bit 21 for punching. The motor 2 is vertically arranged in the middle of the inner chamber of the frame 1, and the top of the frame 1 is provided with an illuminating lamp 5 capable of adjusting the position of the lamp head. The denture positioning plate 8 is slidably arranged on the top of the frame 1. The middle part of the plane of the denture positioning plate 8 is provided with a vertical through hole 81. The drill bit 21 is vertically connected with the output shaft of the motor 2. The through hole 81 and the drill bit 21 are coaxially arranged, and when the denture positioning plate 8 slides down, the drill bit 21 can protrude from the bottom of the dent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com