Post-mix beverage dispenser with cooler

A cooler and post-mixing technology, applied in the field of post-mixing beverage preparation, can solve the problems of wasting energy, inefficiency, and increasing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

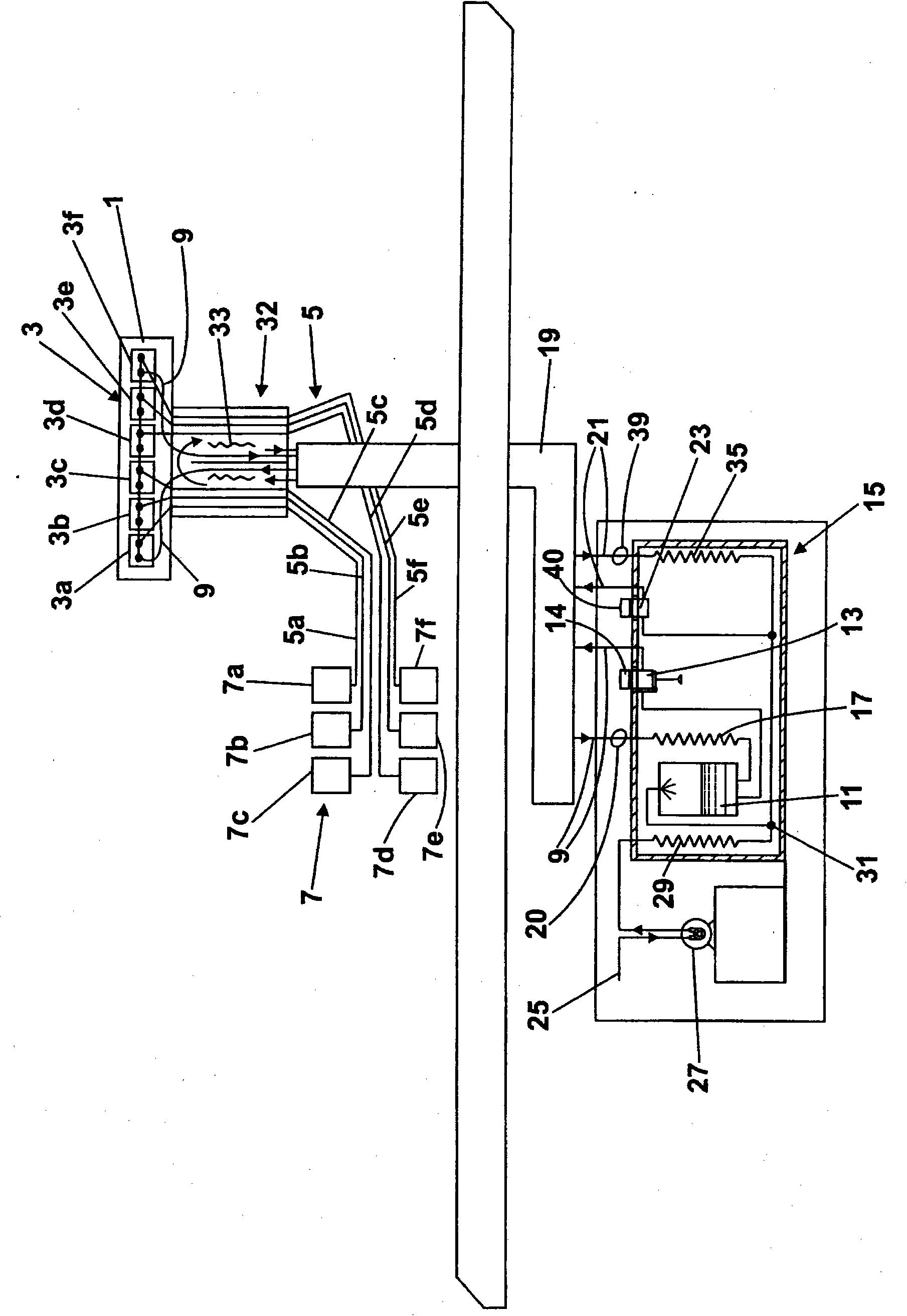

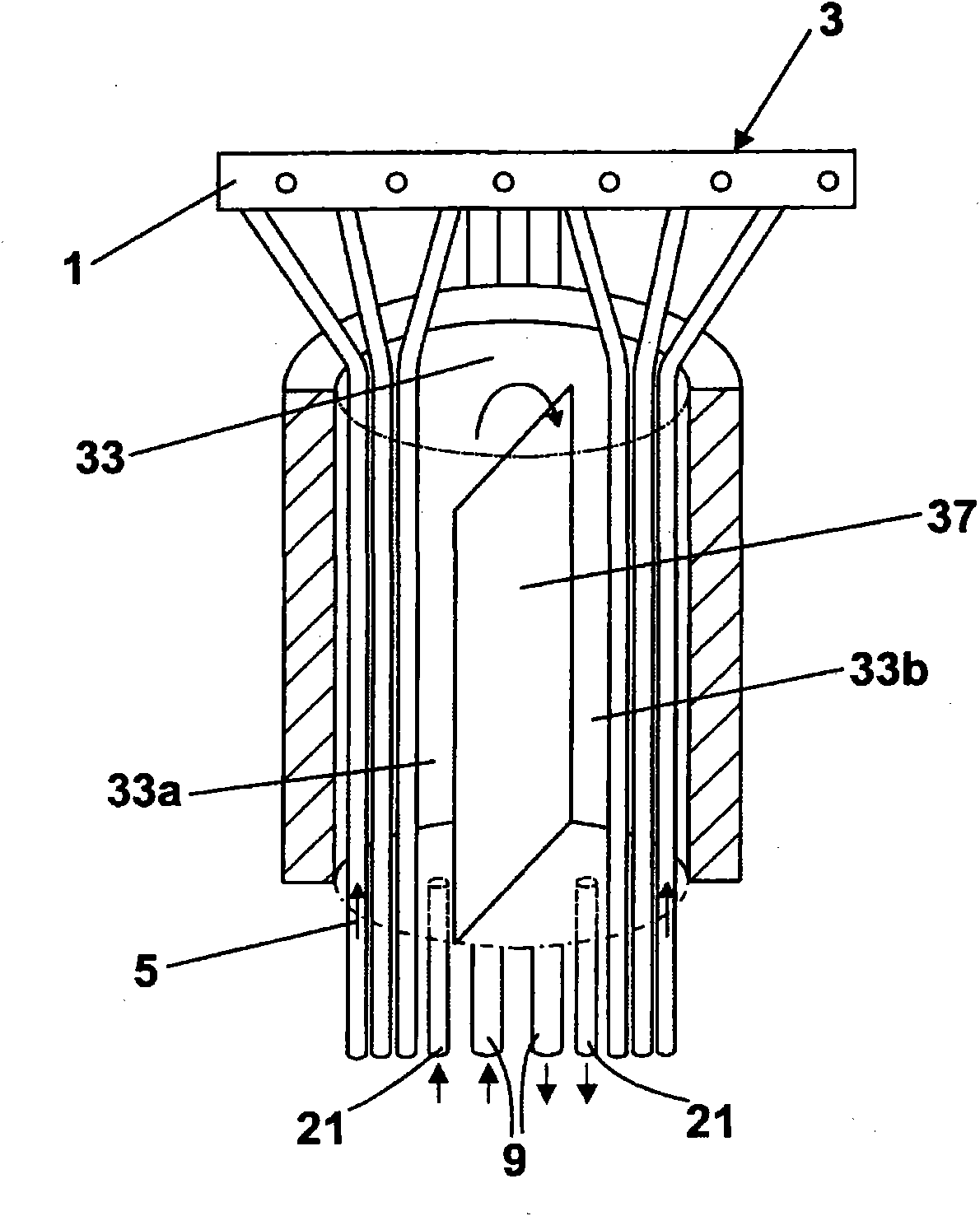

[0051] First refer to the attached figure 1 , which shows a post-mix beverage dispensing system comprising a manifold valve block 1 provided with a plurality of post-mix dispensing valves generally indicated by reference number 3 . In this embodiment, the integrated valve block 1 has six dispensing valves 3a, 3b, 3c, 3d, 3e and 3f, however, it can be understood that the number of dispensing valves can be selected according to requirements.

[0052] The dispensing valve 3 is connected by respective supply conduits, generally indicated by reference numeral 5 , to separate sources of concentrate, generally indicated by reference numeral 7 . In this embodiment, there are six supply lines 5a, 5b, 5c, 5d, 5e and 5f for each dispensing valve 3a, 3b, 3c, 3d, 3e and 3f respectively, and six concentrate sources 7a, 7b , 7c, 7d, 7e and 7f. However, it will be appreciated that such an arrangement is not required and that the number of supply lines and concentrate sources may vary depend...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com