Method for refining sugar by rapidly degrading reed fibers

A reed fiber, rapid degradation technology, applied in the direction of fermentation, etc., can solve the problems of unobvious pretreatment effect, difficult degradation, and not yet seen, and achieve the effect of reducing irradiation cost, increasing irradiation amount, and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A method for fast degrading sugar production of reed fiber of the present invention comprises the following steps:

[0030] 1. Raw material preparation: prepare the reed fiber for mechanical coarse crushing, and then heat-press it to make it with a density of 0.8 g / cm 3 ~0.9 g / cm 3 reed fiber bricks;

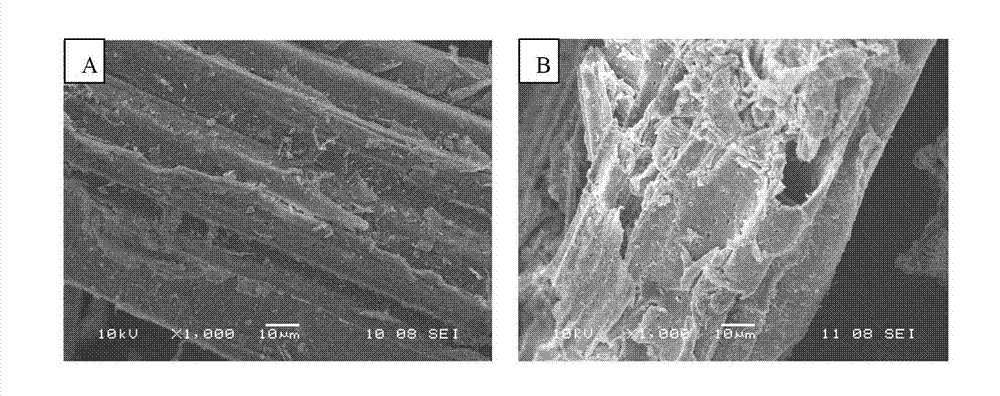

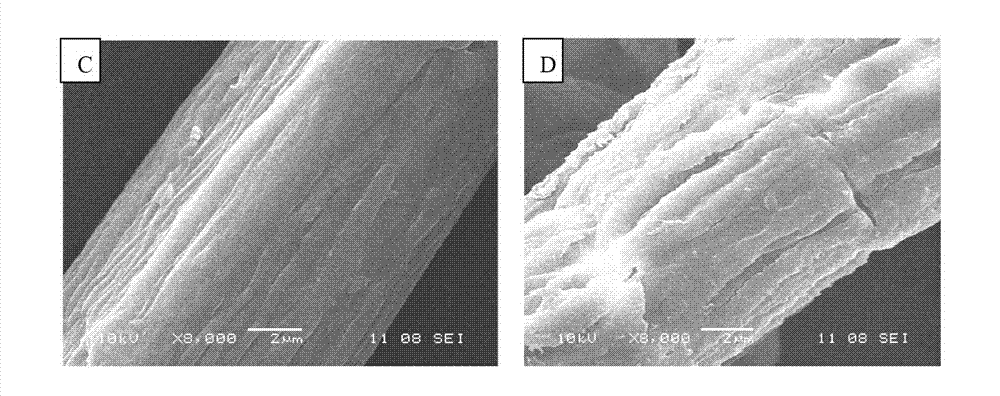

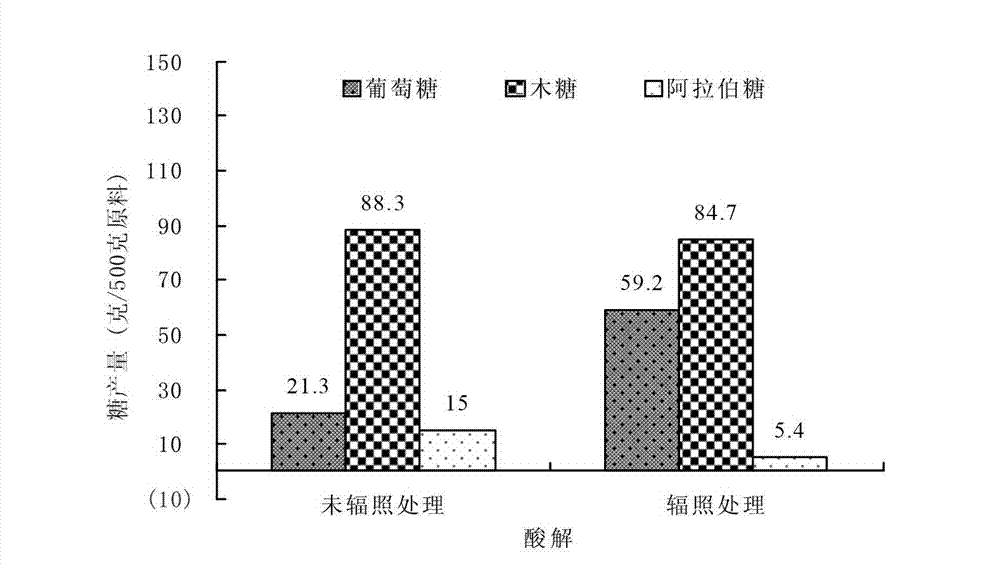

[0031] 2. Irradiation treatment: the above-mentioned reed fiber bricks were irradiated with a dose of 450 kGy 60 Co-γ was irradiated once, crushed into 20-mesh coarse powder, and the dose rate was 20kGy / h during the first irradiation treatment (the electron microscope scanning images of the fiber surface before and after the first irradiation treatment are shown in Fig. figure 1 shown in the A and B diagrams); then the coarse powder was irradiated with a dose of 350 kGy 60 Co-γ is irradiated twice and crushed into a fine powder with a particle size of 200 mesh (density 0.1-0.3 g / cm 3 ), the dose rate during the second irradiation treatment was 20kGy / h (the electron mi...

Embodiment 2

[0036] A method for fast degrading sugar production of reed fiber of the present invention comprises the following steps:

[0037] 1. Raw material preparation: prepare the reed fiber for mechanical coarse crushing, and then heat-press it to make it with a density of 0.8 g / cm 3 ~0.9 g / cm 3 reed fiber bricks;

[0038] 2. Irradiation treatment: the above-mentioned reed fiber bricks were irradiated with a dose of 500 kGy 60 Co-γ was irradiated once, crushed into 20-mesh coarse powder, and the dose rate was 30kGy / h during the first irradiation treatment (the electron microscope scanning images of the fiber surface before and after the first irradiation treatment are shown in Fig. Figure 5 shown in Figure E and Figure F); then the coarse powder is irradiated with a dose of 300 kGy 60 Co-γ was irradiated twice and crushed into a fine powder with a particle size of 200 mesh (density 0.2 g / cm 3 ), the dose rate during the second irradiation treatment was 15kGy / h (the electron micr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com