Large-power electronic product cooling device

A technology for electronic products and heat dissipation devices, which is applied in the heat dissipation application field of high-power electronic products, can solve the problems affecting the service life and working efficiency of high-power electronic products, poor heat dissipation and cooling effect, and limited heat dissipation effect, and achieves light weight and weight reduction. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

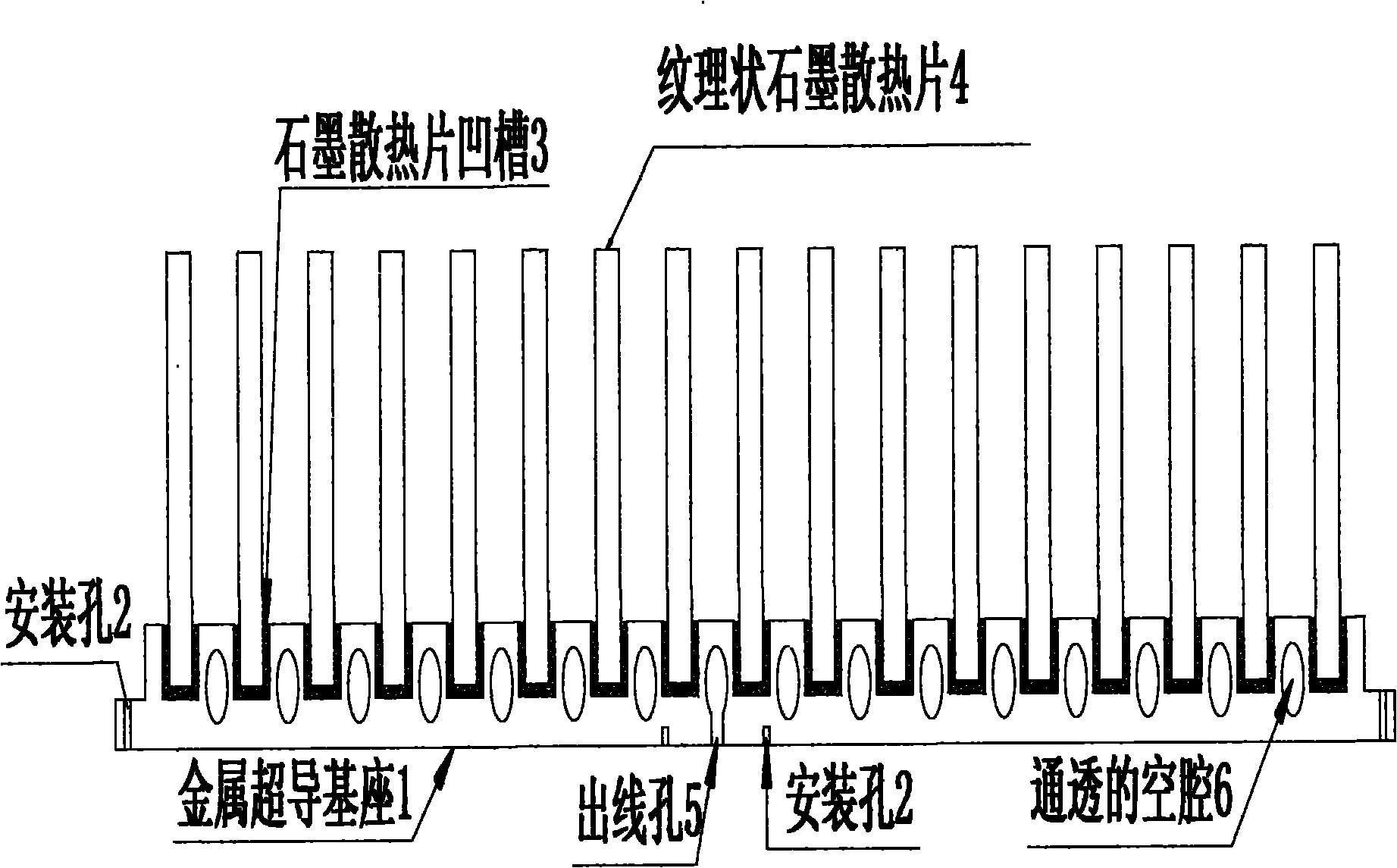

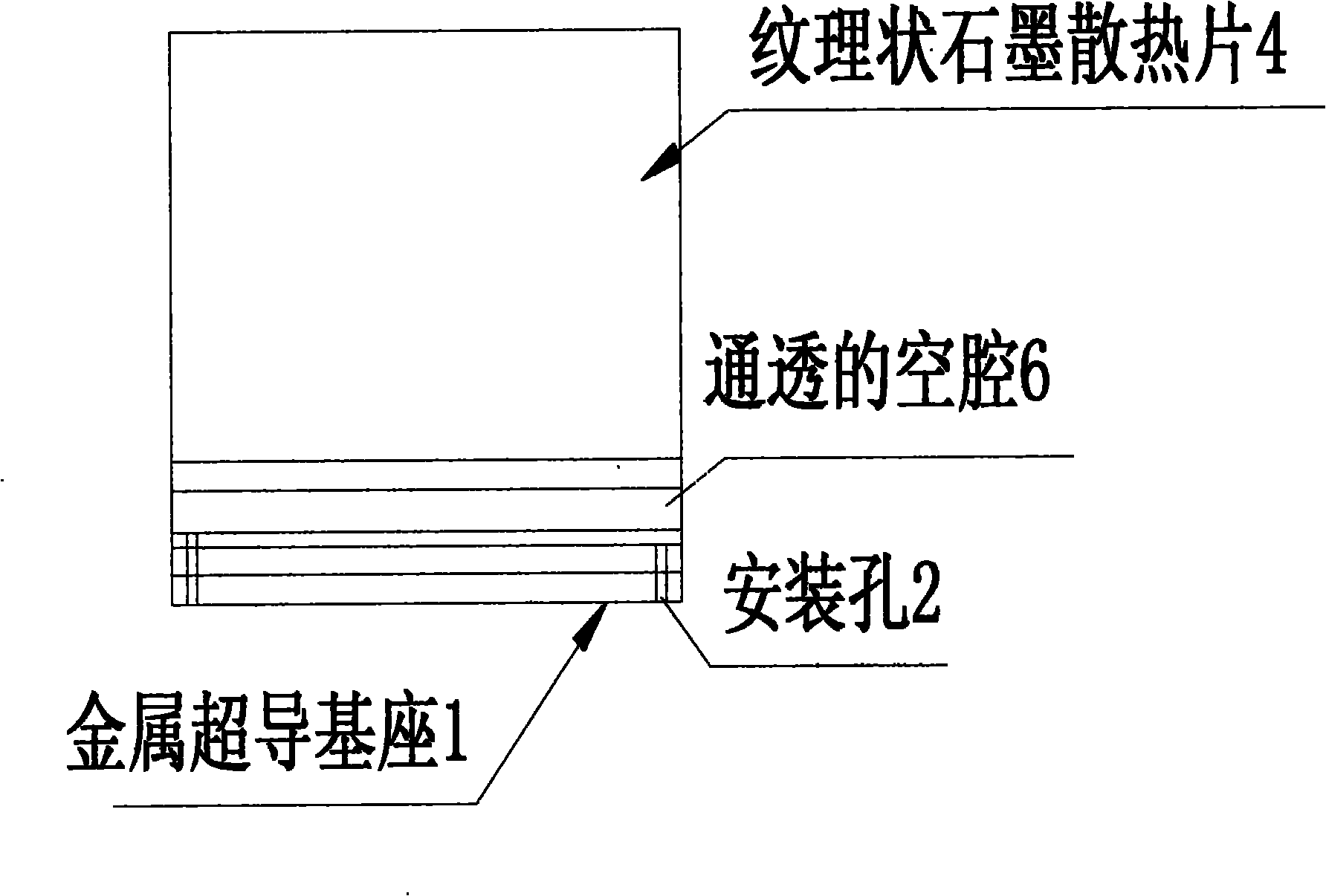

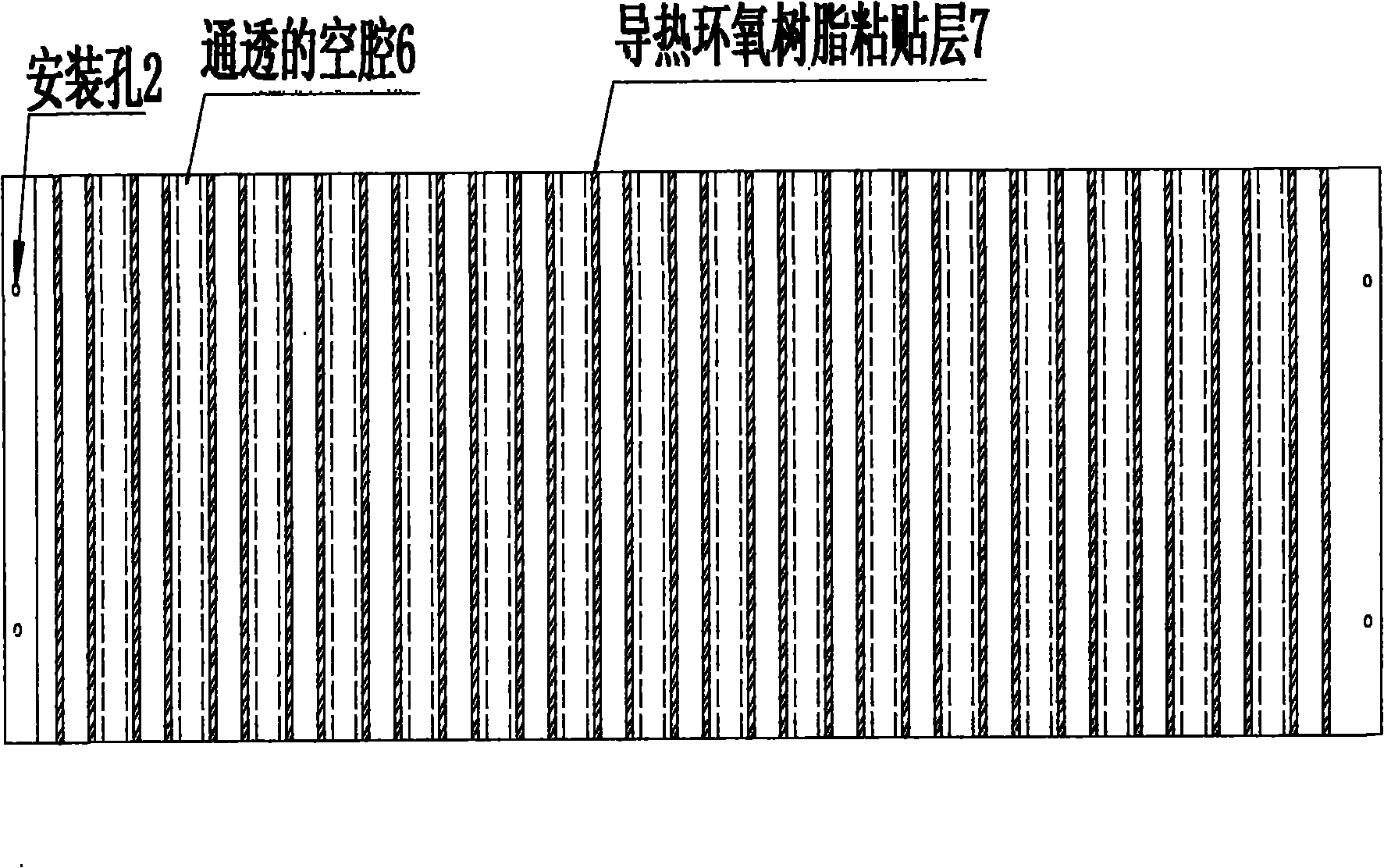

[0019] The other kind of heat dissipation device for high-power electronic products is composed of a graphite heat sink and a metal superconducting base. It is characterized in that, on the metal superconducting base, there is a groove for installing a graphite heat sink, and The groove of the metal superconducting base is matched with the graphite heat sink, and the surface of the graphite heat sink is textured, and this structure can dissipate heat in a larger area. The graphite heat sink is bonded to the metal superconducting base with thermally conductive epoxy resin to keep the radiator light and improve the heat dissipation effect. There are multiple transparent cavities in the metal superconducting base, which is not only convenient for metal superconducting The heat on the base is convected with the outside air, and the weight of the metal superconducting base is greatly reduced. It can be seen that the present invention has simple structure, light weight, easy operati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com