Elliptical continuous twisted tube coaxial heat exchanger

A heat exchanger, coaxial technology, applied in the direction of heat exchanger types, indirect heat exchangers, tubular elements, etc., can solve the problem of not seeing products, etc., to reduce the possibility of fouling, flow distribution and flow velocity uniformity , the effect of flexible structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention is further elaborated below in conjunction with accompanying drawing, but this example is not used to limit the present invention, and every similar structure of the present invention and similar changes thereof should be included in the protection scope of the present invention.

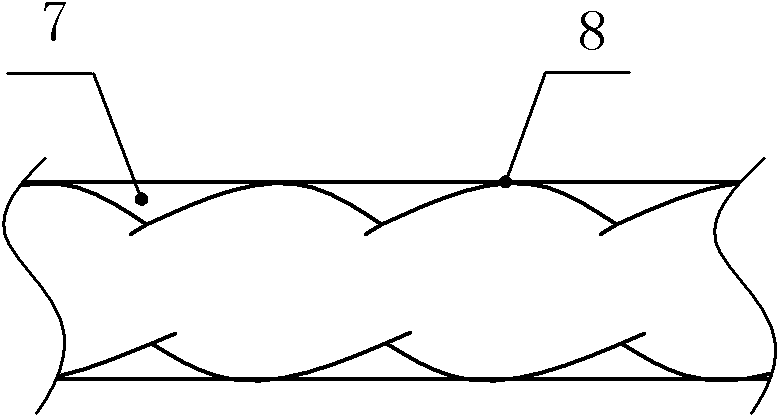

[0053] The main component is an oval continuous twisted tube, which can be rolled or molded. The invention is applicable to the manufacturing process of conventional casing heat exchangers, and is convenient for popularization and application on an industrial scale.

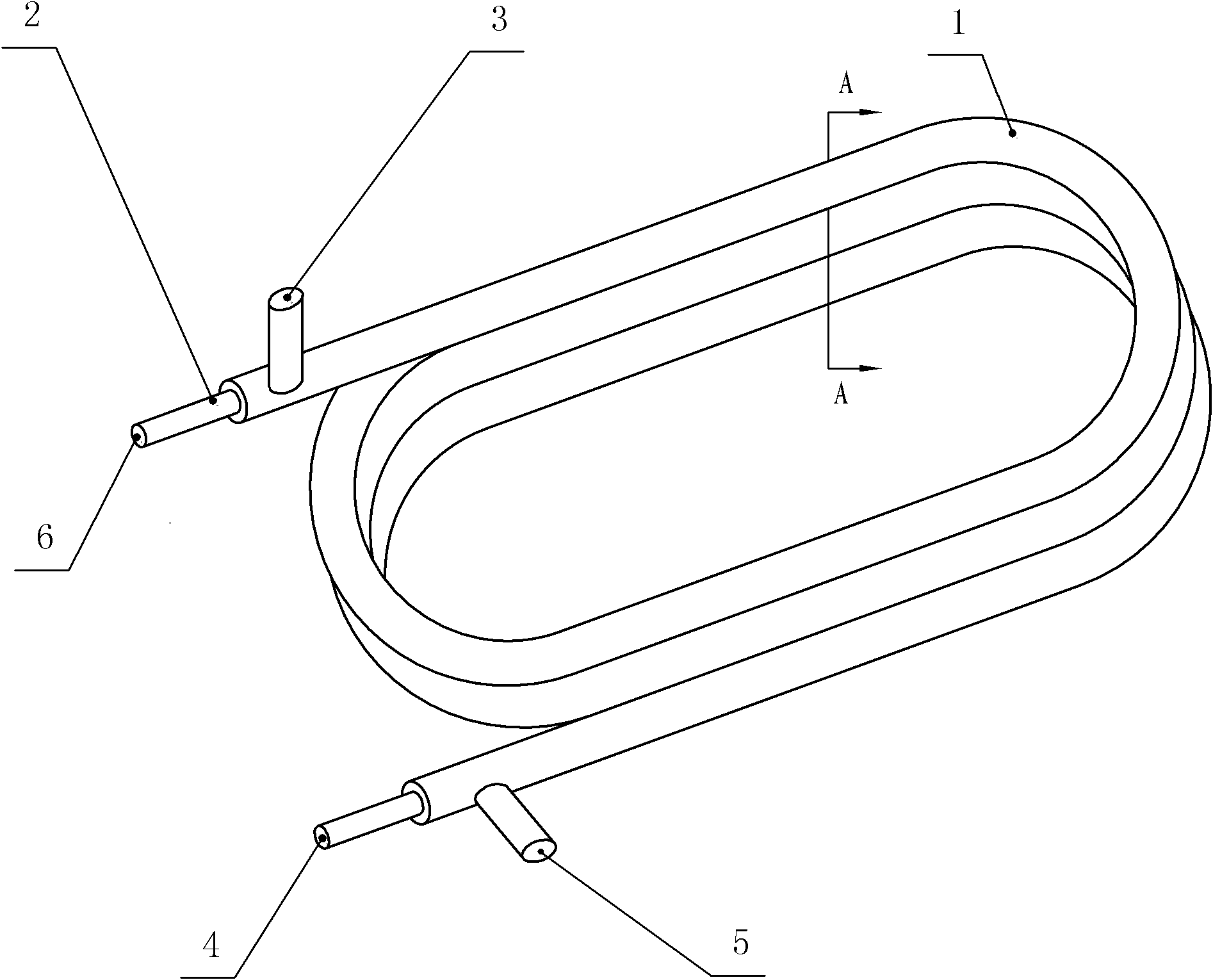

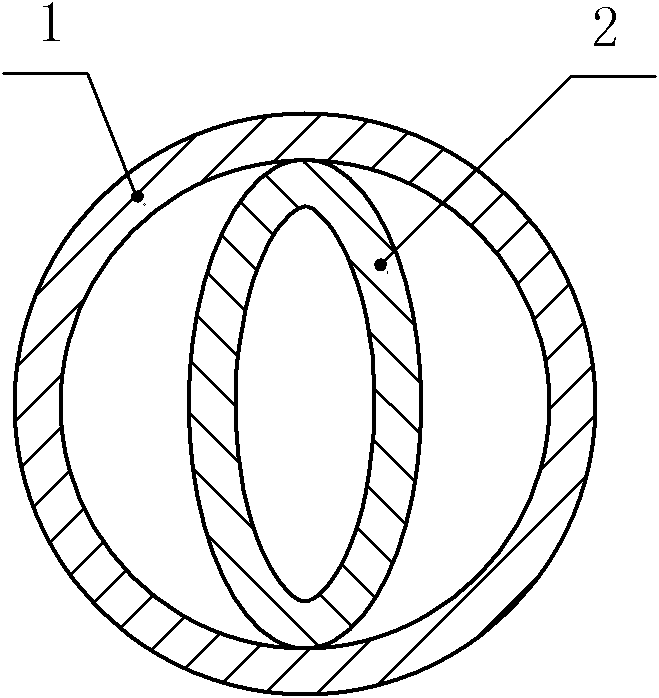

[0054] Such as figure 1 As shown, a coaxial elliptical continuous twisted tube heat exchanger used as a condenser in a heat pump water heater is mainly composed of inner tubes 1 and outer tubes 2 nested. The outer tube 1 is a round tube, and the inner tube 2 is an elliptical continuous twisted tube (also known as a coaxial intersecting tube); the inner tube 2 is installed in the outer tube 1, and the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com