High-speed large-flow valve controlled hydraulic speed generator

A speed generator, large flow technology, applied in fluid pressure actuation devices, servo motor components, mechanical equipment, etc., can solve the problems of strict oil pollution, slow opening speed, low degree of automation, etc. Flow control, avoid secondary collision, achieve the effect of quick opening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

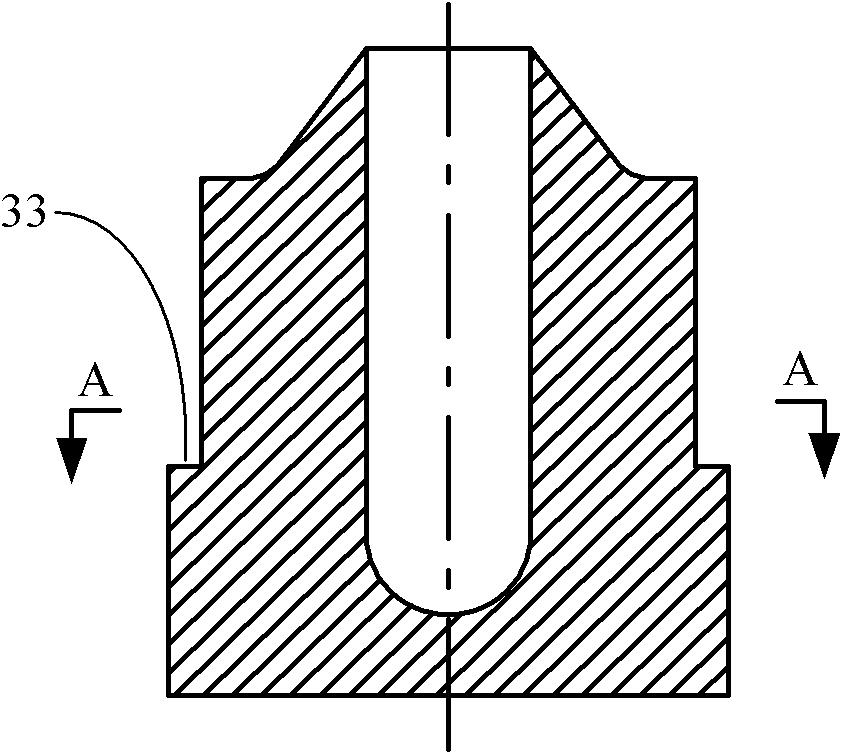

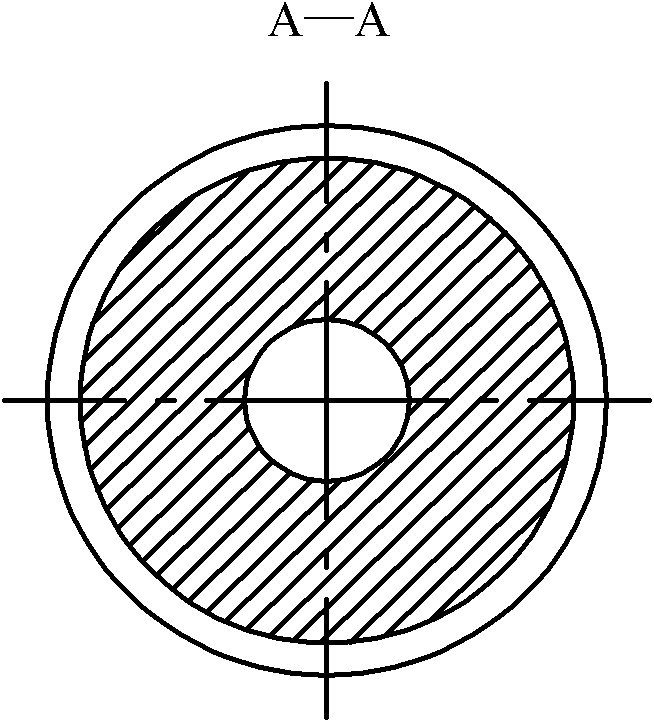

[0011] Such as figure 1 As shown, the present invention includes a pressure source, a high-speed and large-flow control device 38 and a hydraulic cylinder 37. The accumulator 30 is connected with the inlet passage 16 of the high-speed and large-flow control device, and the hydraulic cylinder 37 is connected with the outlet passage 19 of the high-speed and large-flow control device. Sealed to prevent leakage. The pressure source provides pressure fluid for the hydraulic cylinder 37, and the high-speed and large-flow control device 38 controls the movement speed of the piston assembly of the hydraulic cylinder 37.

[0012] The pressure source includes an accumulator 30 , an air charging valve 28 and a liquid charging valve 27 , and the air charging valve 28 and the liquid charging valve 27 are respectively connected to the accumulator 30 .

[0013] The high-speed and large-flow valve 38 includes a valve body 13, a piston spool 18, an adjustable flow valve 24, an on-off valve 23...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com