High-frequency drawing casting method for tin phosphorus bronze

A tin-phosphorus bronze and high-frequency technology is applied in the field of high-frequency casting of tin-phosphorus copper alloys, which can solve the problems of coarse and uneven ingot structure, low production efficiency, short casting time, etc. The effect of reducing production costs and reducing billet cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

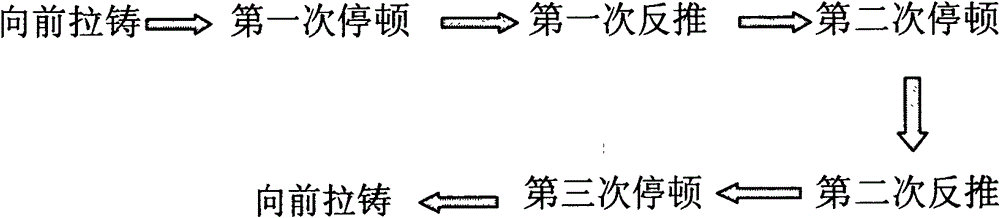

[0014] When drawing casting, first set the program on the control system of the haul-off machine according to the data in the table below, start drawing at a drawing speed of 90mm / min, and after drawing 100 times (period, the same below); Increase the speed to 120mm / min, draw casting 100 times; then increase the speed to 150mm / min, draw casting 100 times; finally increase the casting speed to 180mm / min, keep this casting speed for constant production, and cast during the casting process The temperature is maintained at 1950-1980°C, and the pressure of the cooling water is controlled between 0.55-0.65MPa. The metallographic diagram of the billet is as follows figure 2 shown.

[0015]

[0016]

Embodiment 2

[0018] When casting, first set the program on the control system of the haul-off machine according to the data in the table below, start pulling at a casting speed of 90mm / min, and increase the casting speed to 120mm / min after casting 90 times Draw casting 80 times, then increase the speed to 150mm / min, after drawing 80 times, increase the casting speed to 180mm / min, draw casting 80 times, finally increase the casting speed to 210mm / min, keep this The casting speed is stable, the casting temperature is kept at 1950-1980°C during the drawing casting process, and the pressure of the cooling water is controlled between 0.55-0.65MPa.

[0019]

Embodiment 3

[0021] When drawing casting, first set the program on the control system of the tractor according to the data in the table below, first start drawing casting at a casting speed of 90mm / min, after drawing 100 times, increase the casting speed to 120mm / min, After 80 times of casting, increase the speed to 150mm / min; 80 times. Finally, after raising the casting speed to 240mm / min, maintain the casting speed for stable production. During the casting process, the casting temperature is kept at 1950-1980°C, and the pressure of cooling water is controlled between 0.55-0.65MPa. The metallographic diagram of the billet is as follows image 3 shown.

[0022]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com