Rare-earth modified molecular-sieve dehumidification adsorbent paper sheet and preparation method thereof

A technology of rare earth modification and molecular sieve, which is applied in separation methods, chemical instruments and methods, and other chemical processes. It can solve problems such as small pore size, large heat energy consumption, and difficult desorption, so as to improve service life and save energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

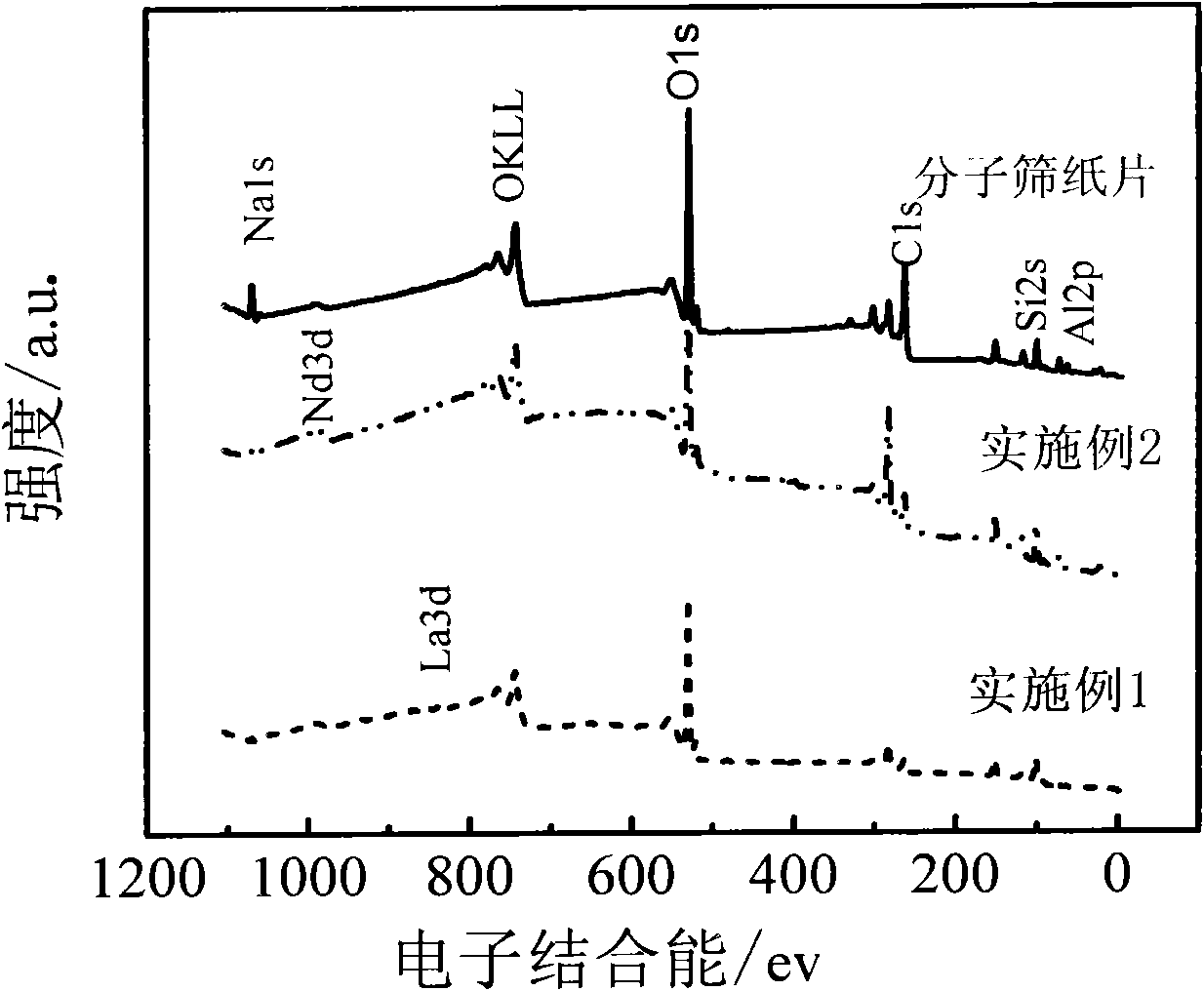

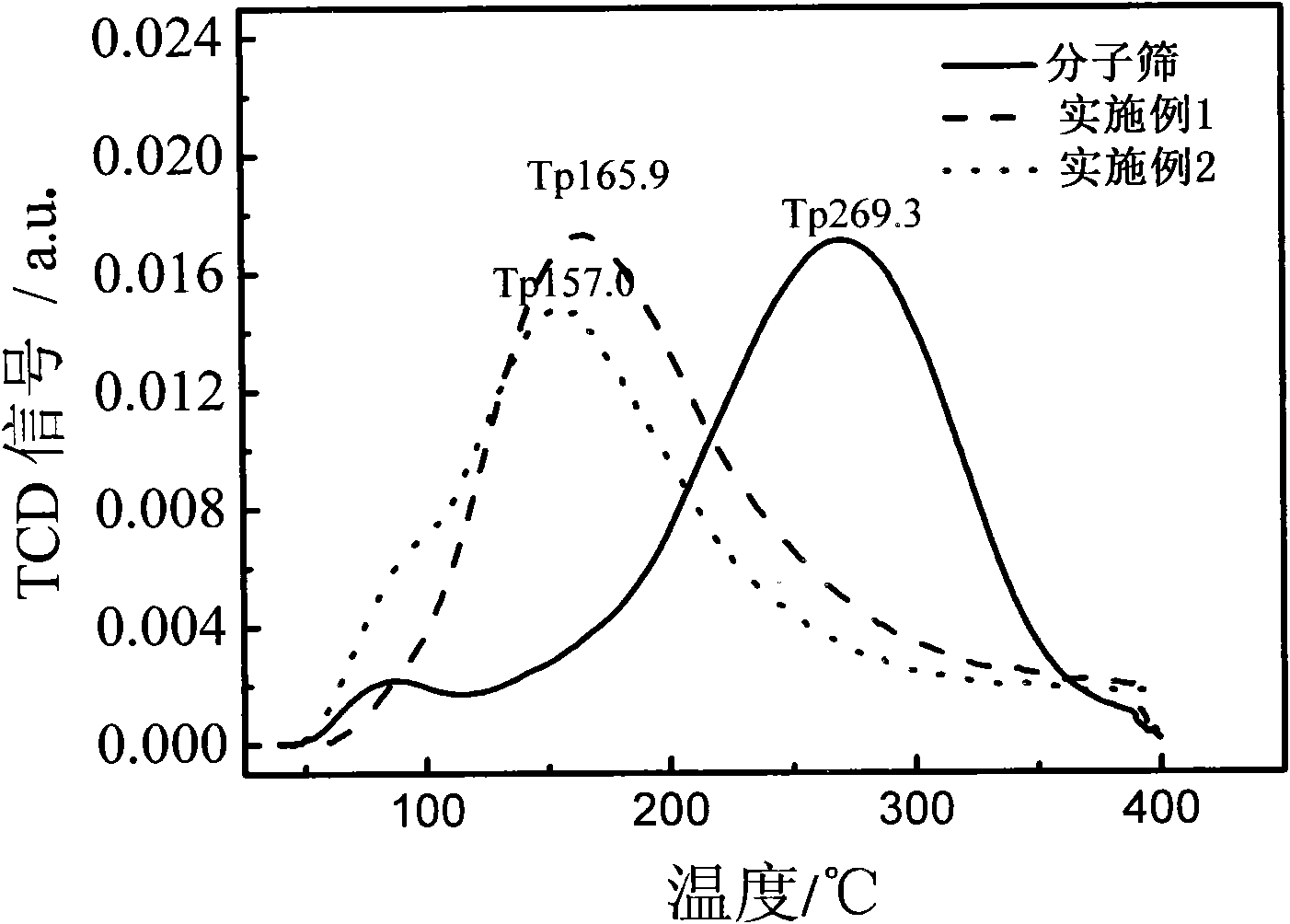

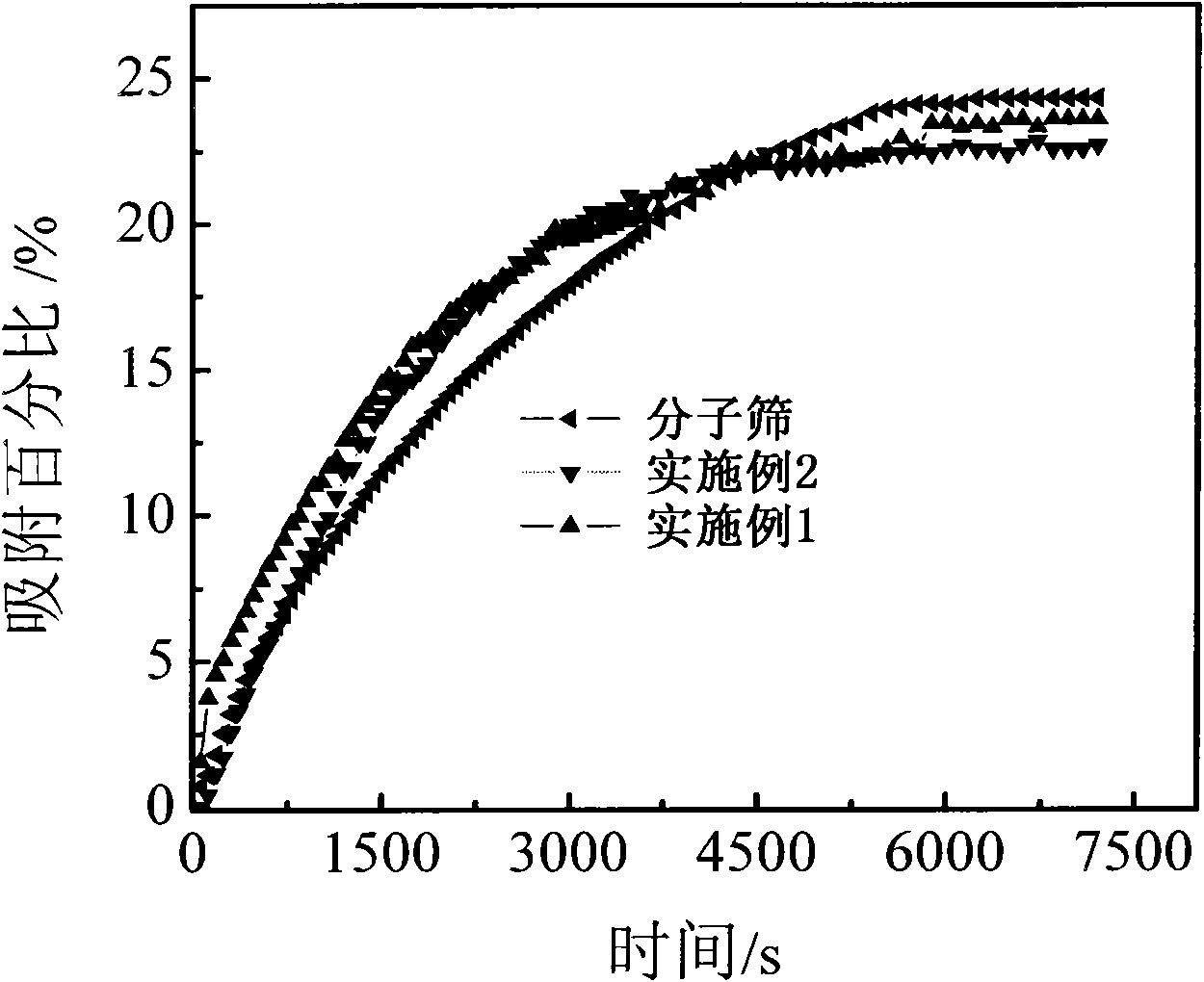

[0034] (1) At room temperature, in a 5L round plastic beaker, add 500mL of hydrochloric acid, then slowly add 0.5kg of lanthanum oxide, stir while adding, after the lanthanum oxide powder is completely dissolved, add 3L of distilled water to dilute, and dilute with 2mol L -1 Ammonia water is used to adjust the pH value to 5 to obtain an acidic rare earth lanthanum solution.

[0035] (2) In a 2L round plastic beaker, measure 1L of the above-mentioned acidic rare earth lanthanum solution, add 200g of 13X molecular sieve with an average particle size of 5 μm, heat up to 60°C, and ion exchange the molecular sieve with the rare earth ion under stirring. Filter the above suspension to obtain a filter cake, disperse it in a square porcelain basin and dry it for 2 hours, then air-dry it at 150°C for 4 hours to obtain a powder, transfer it to a ceramic crucible, and then place it in a programmed sintering furnace for activation. The sample is first rapidly (heating rate 15°C·min-1 , th...

Embodiment 2

[0038] (1) At room temperature, add 500mL of hydrochloric acid to a 5L round plastic beaker, then slowly add 0.5kg of lanthanum oxide, and stir while adding. After the neodymium oxide powder is completely dissolved, add 3L of distilled water to dilute, and use 1mol L -1 Ammonia water is used to adjust the pH value to 5 to obtain an acidic rare earth neodymium solution.

[0039] (2) In a 2L round plastic beaker, measure 1L of the above-mentioned acidic rare earth neodymium solution, add 200g of 13X molecular sieve with an average particle size of 5μm, heat up to 50°C, and ion exchange the molecular sieve with the rare earth ion under stirring. Filter the above suspension to obtain a filter cake, disperse it in a square porcelain basin and dry it for 2 hours, then air-dry it at 120°C for 4 hours to obtain a powder, transfer it to a ceramic crucible, and then place it in a programmed sintering furnace for activation. The sample was heated up rapidly to 400°C for 30 minutes, then ...

Embodiment 3

[0042] (1) At room temperature, in a 5L round plastic beaker, add 500mL of hydrochloric acid, then slowly add 0.5kg of cerium oxide, and stir while adding. After the cerium oxide powder is completely dissolved, add 3L of distilled water to dilute, and use 3mol·L -1 Ammonia water is used to adjust the pH value to 5 to obtain an acidic rare earth cerium solution.

[0043] (2) In a 2L round plastic beaker, measure 1L of the above-mentioned acidic rare earth cerium solution, add 200g of 13X molecular sieve with an average particle diameter of 5 μm, heat up to 70°C, and ion exchange the molecular sieve with the rare earth ion under stirring. Filter the above suspension to obtain a filter cake, disperse it in a square porcelain basin and dry it for 2 hours, then air-dry it at 170°C for 4 hours to obtain a powder, transfer it to a ceramic crucible, and then place it in a programmed sintering furnace for activation. The sample was heated up rapidly to 450°C for 30 minutes, and then sl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com