Dryer for lacquering facility

A coating equipment and dryer technology, applied in the dryer field, can solve problems such as high unit cost and achieve the effect of reducing harmful substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

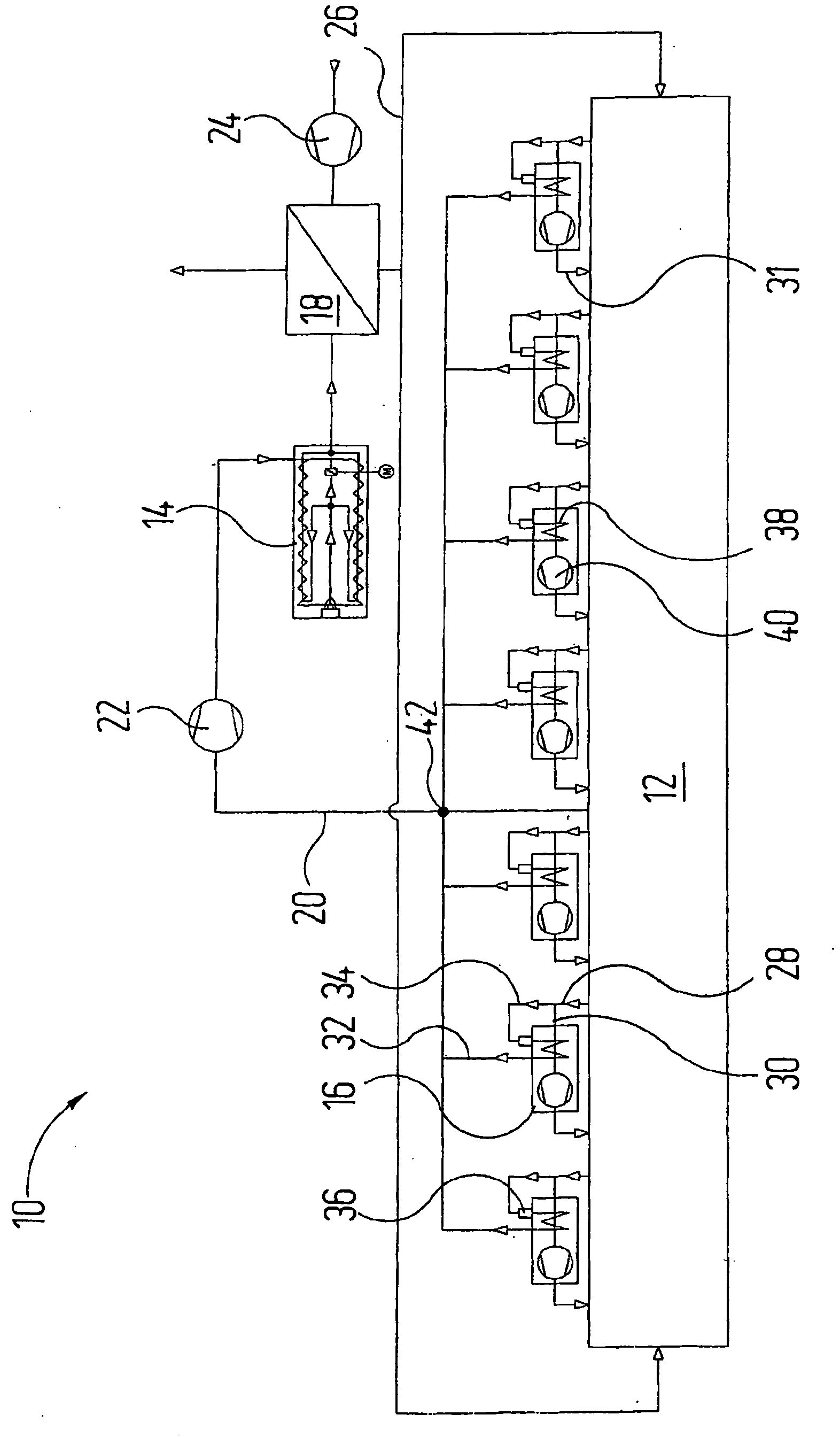

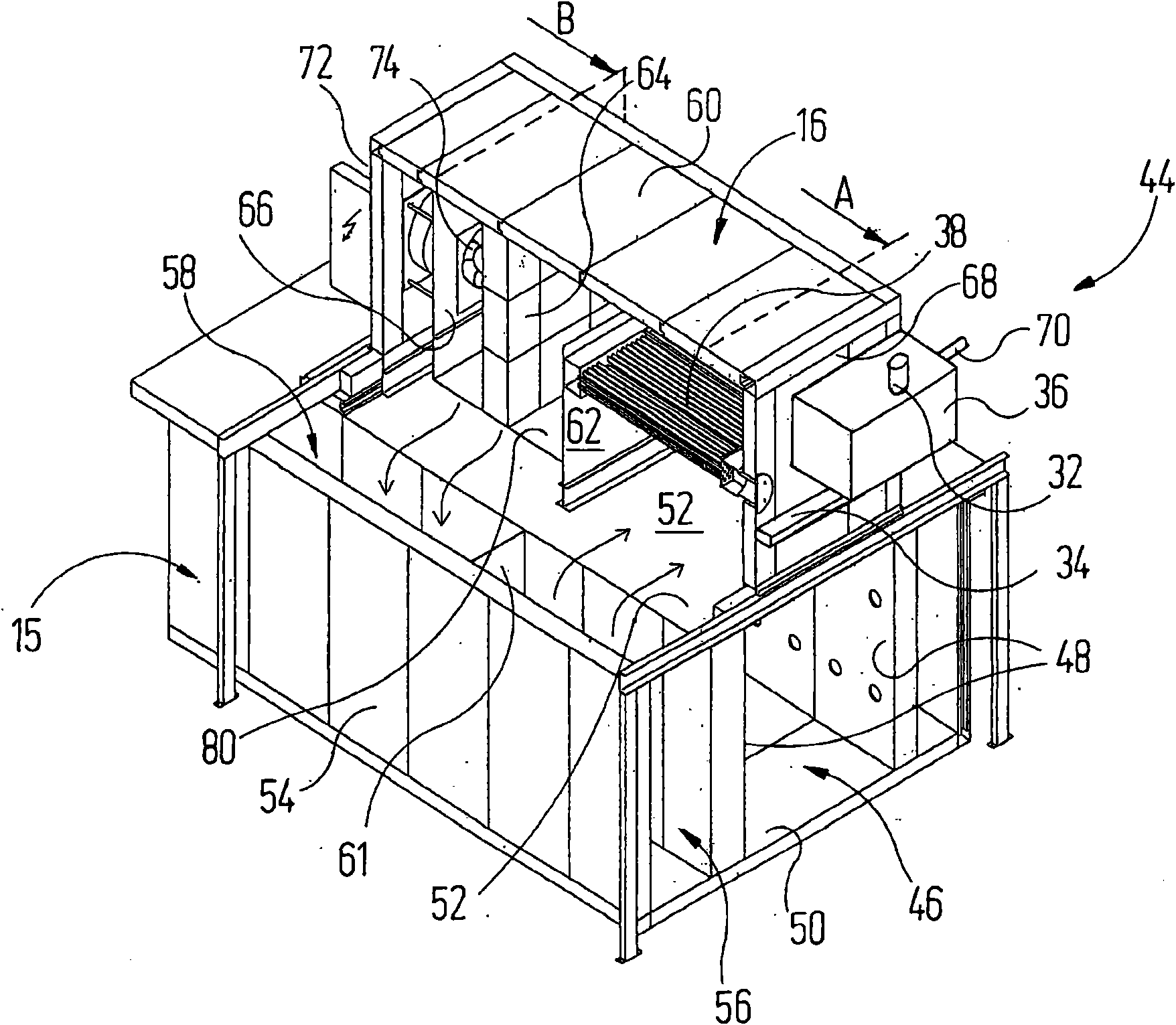

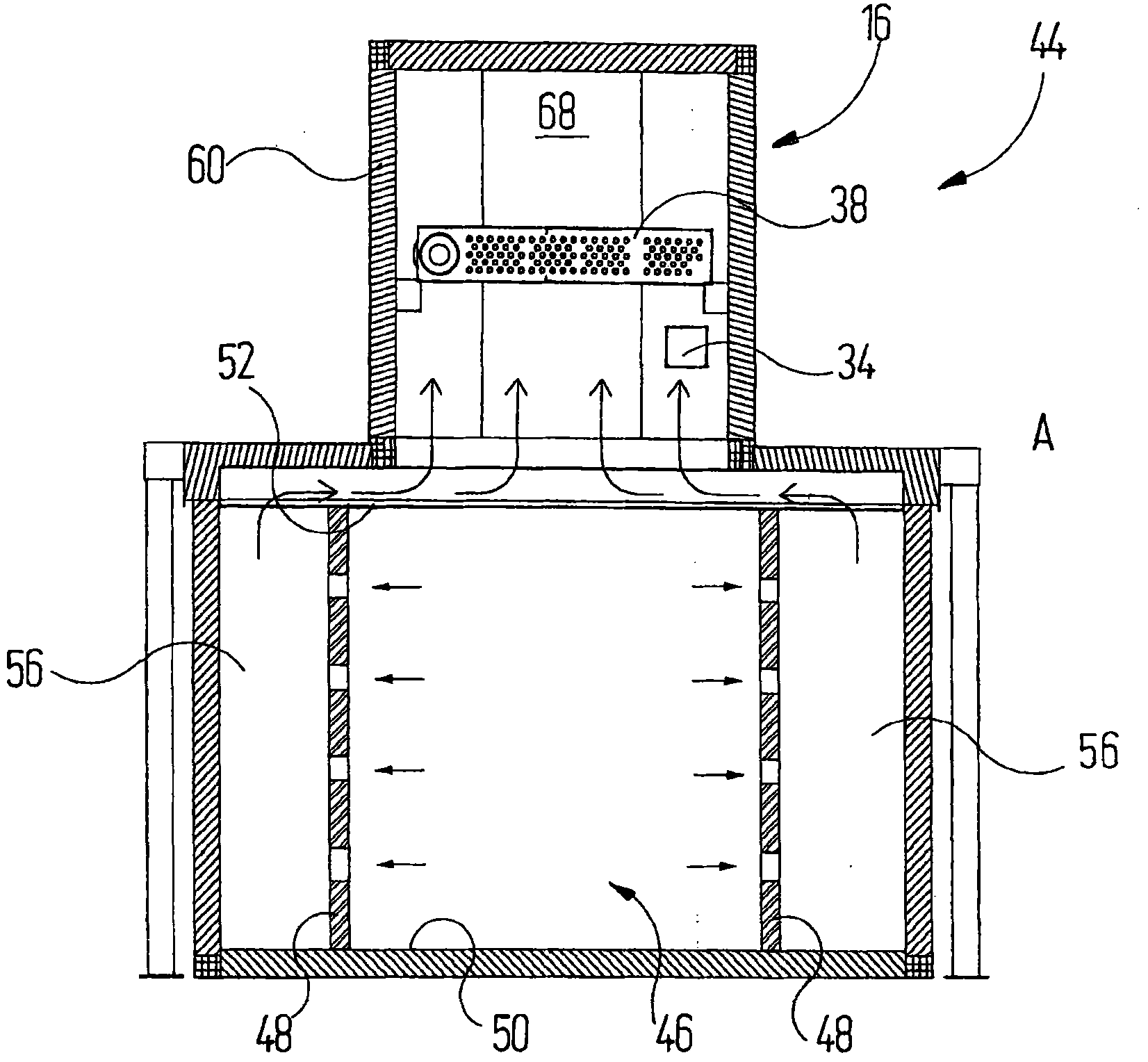

[0031] exist figure 1 The dryer 10 schematically shown in FIG. 2 comprises a dryer housing 12 through which a motor vehicle body (not shown) can pass during continuous operation. Heated air is supplied to the dryer housing 12 in order to start and / or accelerate the drying process of the paint applied to the motor vehicle body and / or to promote crosslinking of the paint. The dryer housing 12 is perpendicular to figure 1 There is a substantially rectangular cross-section in the sectional plane of the drawing plane, as can also be determined by Figures 2 to 4 as seen in the view.

[0032] A thermal post-combustion device 14 , a plurality of heating units 16 and a heat exchanger 18 with the same structure are arranged above the dryer shell 12 .

[0033] The thermal afterburner 14 is a gas burner that mixes exhaust air from the dryer shell 12 supplied via an exhaust air duct 20 and an exhaust air blower 22 for conveying the exhaust air with natural gas and makes the The mixtur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com