Quantitative analysis method for measuring trace nickel in water by microwave digestion-flame atomic absorption spectrometry (FAAS)

A technology of microwave digestion and quantitative analysis, which is applied in the preparation of test samples and the measurement of color/spectral properties. and other problems, to achieve the effect of reducing pollution and harm to the human body, saving measurement costs, and low instrument maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

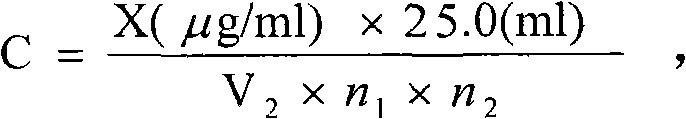

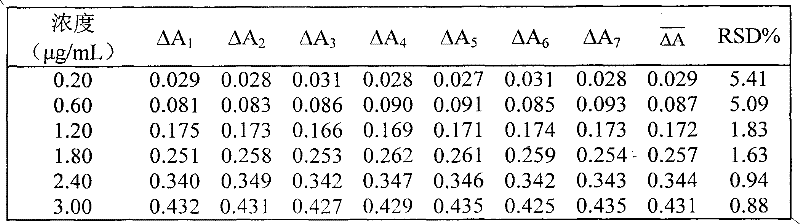

Method used

Image

Examples

Embodiment 1

[0081] Determination of nickel content and recovery rate experiment in environmental engineering laboratory wastewater of Shenyang University of Technology:

[0082] (1) Microwave digestion pretreatment of samples: accurately pipette 5.0ml water samples from three waste liquid buckets into microwave digestion tanks (take 3 copies of each sample for parallel test, and take 3 copies for recovery rate experiment at the same time), Add 10.0ml of 70.0% nitric acid, 1.0ml of 40.0% hydrofluoric acid and 1.0ml of 30.0% hydrogen peroxide, cover the lid, insert it into the protective cover, and put a burst membrane on it. At the same time, prepare a blank solution, and then put it into the microwave digestion apparatus Sample digestion. Digestion pressure 2.5MPa, digestion time 15min. After the digestion program is over, when the temperature reaches 40°C, turn on the microwave digestion apparatus and take out the digestion tank; transfer the sample in the digestion tank to a beaker, he...

Embodiment 2

[0092] Determination of nickel content and recovery rate experiment in Taizi River water of Liaoyang City:

[0093] (1) Sample concentration and microwave digestion pretreatment: Accurately remove the detected leaves and debris and filter them through a filter membrane with a pore size of 0.45 μm to remove suspended particles in Taizi River in March, May, and July 2010. 2000.0ml in a 2000ml beaker (take 3 parts of each sample for parallel experiments, and take 3 parts at the same place for recovery experiment), evaporate and concentrate to 10.0ml (n 1 =200). Take 10 digestion tanks, add 5.0ml of concentrated water sample to 9 digestion tanks, add 10.0ml of 70.0% nitric acid, 1.0ml of 40.0% hydrofluoric acid and 1.0ml of 30.0% hydrogen peroxide, cover the lids and insert the protective cover In, and put the burst membrane, while preparing a blank solution. Then put it into a microwave digestion apparatus for sample digestion. The digestion pressure is 2.5MPa, and the digesti...

Embodiment 3

[0102] Determination of nickel content and recovery rate in coal washing water of a coal washing plant in Dengta City

[0103] (1) Sample microwave digestion pretreatment: Accurately pipette 5.0ml of water samples of coal washing water in the morning, middle and evening shifts of three shifts in May, filtered through a filter membrane with a 0.45 μm pore size to remove particles suspended in the water (3 Add 10.0ml of 70.0% nitric acid, 1.0ml of 40.0% hydrofluoric acid and 1.0ml of 30.0% hydrogen peroxide to the digestion tank, cover the lid, insert it into the protective cover, and put the burst membrane on it, and prepare a blank solution at the same time . Then put it into a microwave digestion apparatus for sample digestion, the digestion pressure is 2.5MPa, and the digestion time is 30min. After the digestion program is finished, when the temperature display reaches 38°C, turn on the microwave digestion apparatus, take out the digestion tank and transfer the sample to a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com