Fiber reinforce plastic (FRP)-rubber-steel composite pipe concrete structure

A technology for concrete structures and composite pipes, applied in building structures, buildings, etc., can solve the problems of "multi-level fortification performance-based design, low limit strain capacity, early FRP failure, etc., and achieve good absorption of vibration load energy." , Excellent seismic performance, the effect of solving the problem of steel pipe corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

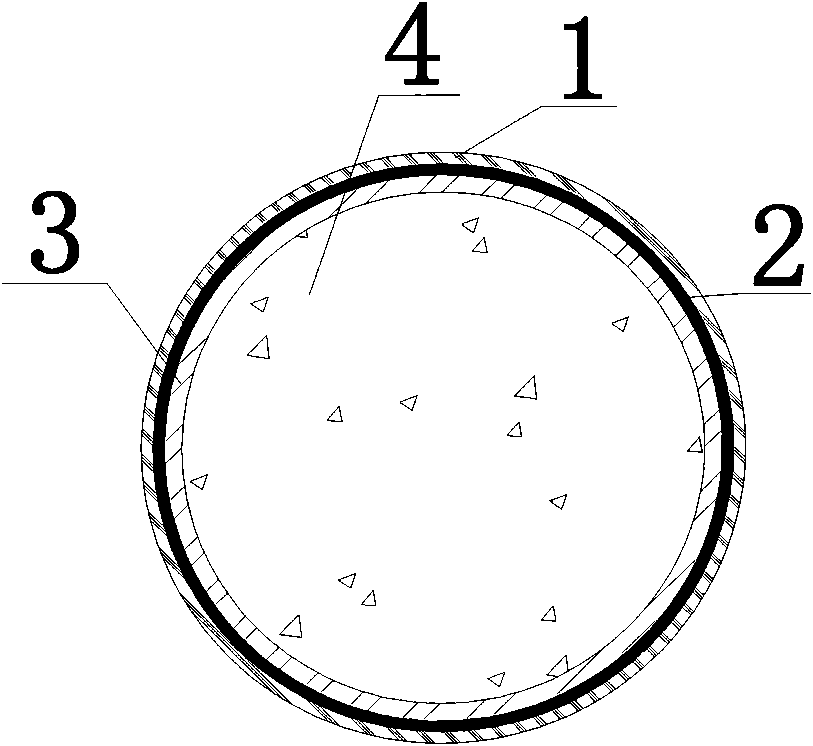

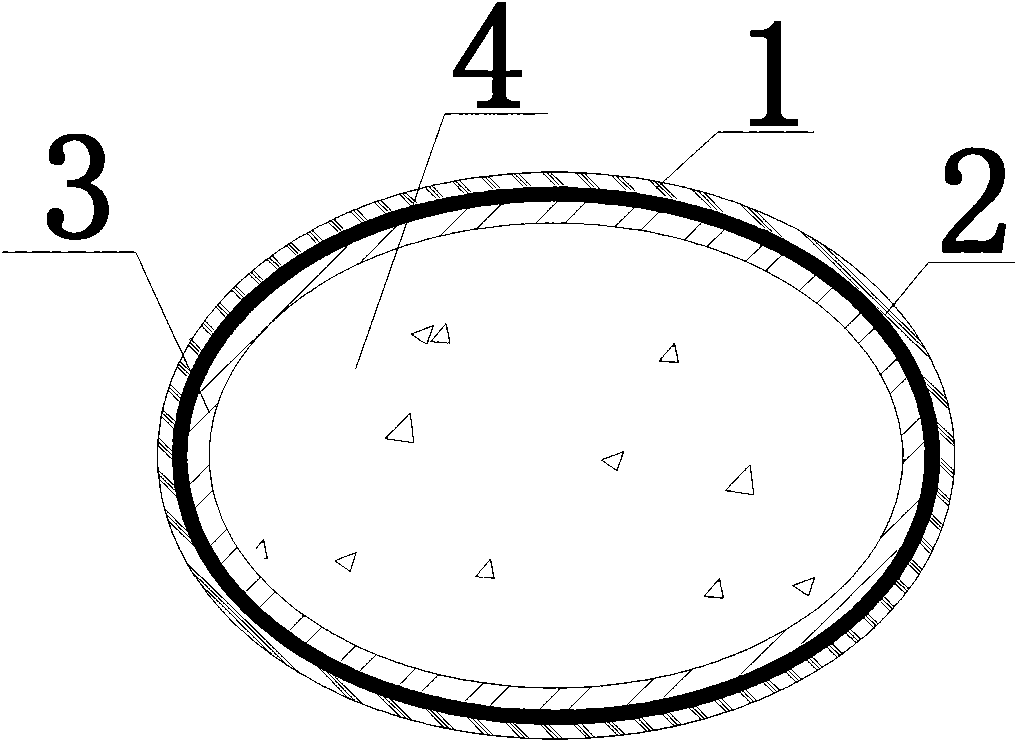

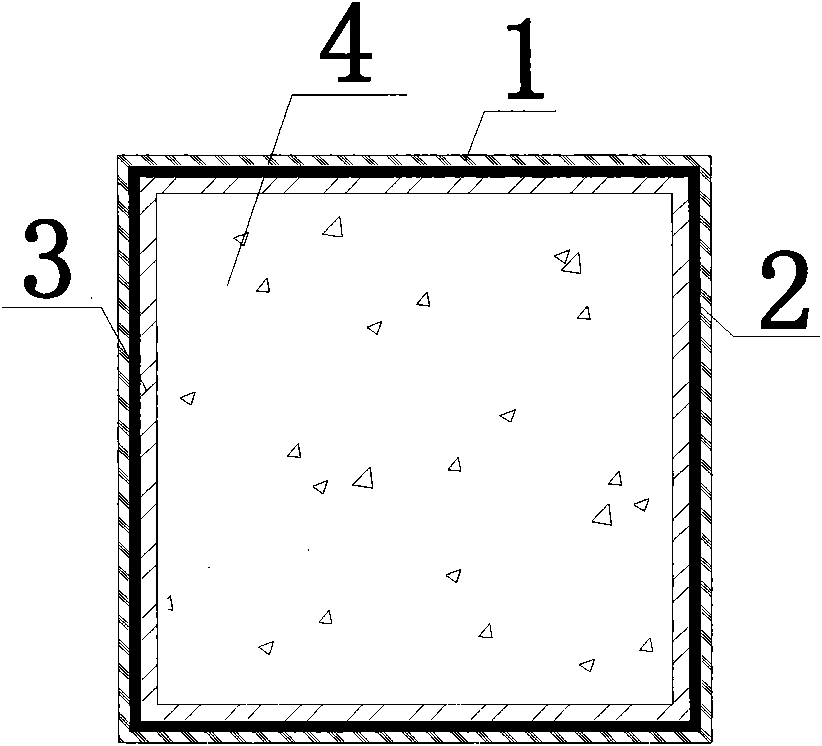

[0028]In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings. The present invention provides a FRP-rubber-steel composite tubular concrete structure, which is characterized in that the structure comprises four parts: FRP layer 1, rubber layer 2, steel pipe 3 and core concrete 4, which are jointly formed from outside to inside; wherein, FRP layer 1, The three parts of the rubber layer 2 and the steel pipe 3 are bonded by resin to form a composite pipe as a whole, the core concrete 4 is filled inside the composite pipe, and the composite pipe exerts restraint and reinforcement on the inner core concrete 4 .

[0029] The FRP layer 1, the rubber layer 2 and the steel pipe 3 are located around the core concrete 4, the steel pipe 3 is the first layer of restraint material of the core concrete 4, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com