Maleic anhydride melt-grafted ABS and preparation method thereof

A technology of maleic anhydride and melt grafting, which is applied in the field of low-odor ABS melt grafting maleic anhydride and its preparation, can solve the problems of large interphase interface, irritating odor, poor mechanical properties of alloy materials, etc. Fluidity and heat distortion temperature, excellent application effect, good working environment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

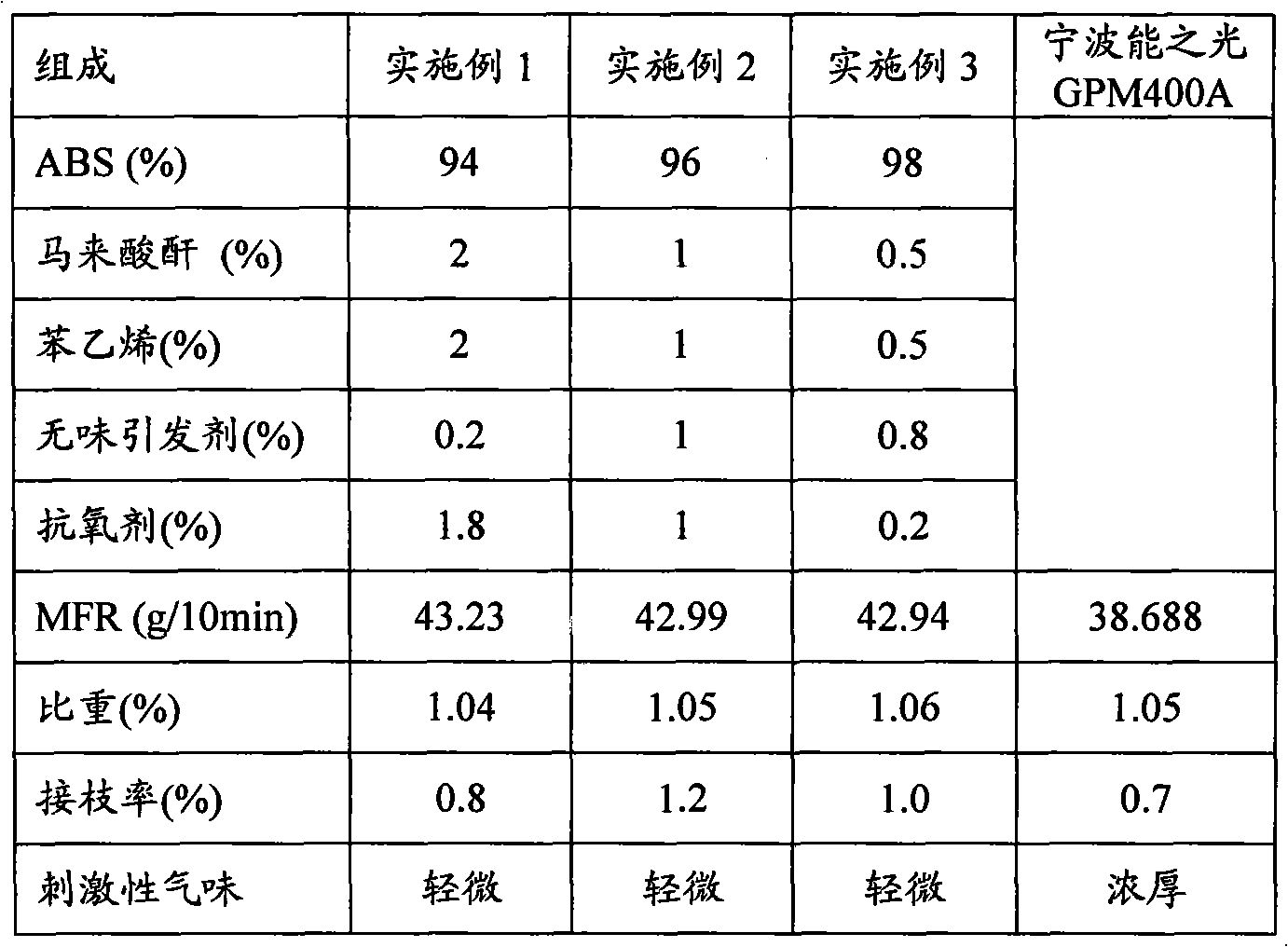

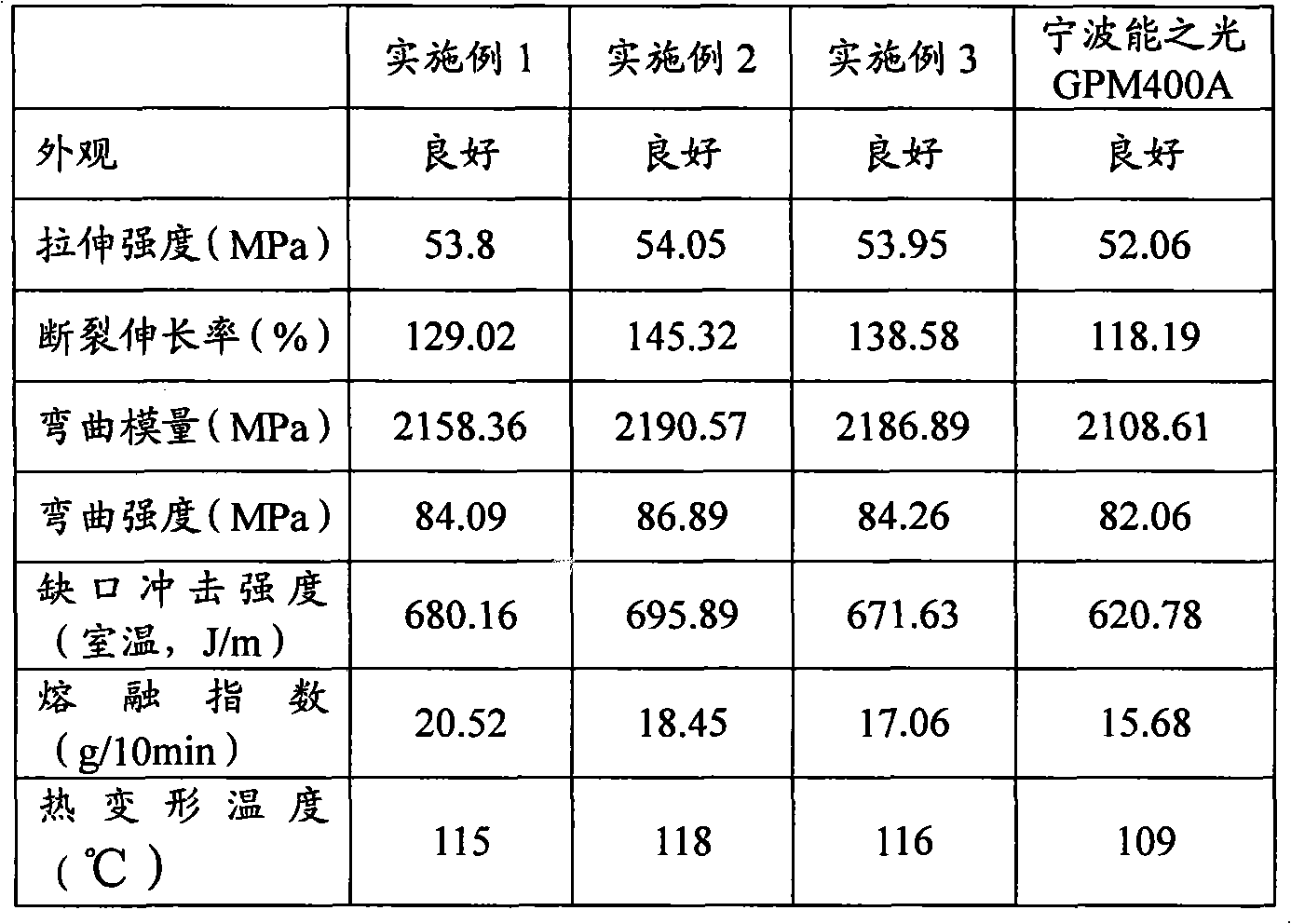

[0032] The preparation method of ABS melt-grafted maleic anhydride of the present invention, at first weighs required raw material according to parts by weight, contains 94~98 parts of ABS, 0.5~2 parts of maleic anhydride in every hundred parts by weight of raw materials; 0.5-2 parts of ethylene; 0.2-1 part of odorless initiator; 0.2-2 parts of antioxidant.

[0033] Weigh an appropriate amount of maleic anhydride, odorless initiator, and antioxidant into styrene and stir in order, and stir for the first time;

[0034] In a preferred embodiment of the present invention, described maleic anhydride (also known as maleic anhydride) has a weight-average molecular weight of 98-99, a melting point of 52.8°C, and a relative density (water=1g / cm3) of 1.48g / cm3, analytically pure.

[0035] In a preferred embodiment of the present invention, the odorless initiator is BIBP, which is a white to pale yellow powder or solid, with a content %≥98, a melting point of 45°C-55°C, and a theoreti...

Embodiment 1

[0042] Dissolve 2% maleic anhydride, 0.2% odorless initiator, and 1.8% antioxidant into 2% styrene liquid, pre-mix for 3 minutes in a high-speed batch mixer, then add baked 94% ABS to high-speed Ingredients in a blender, then blend together for 5 minutes and set aside. Put the stirred mixture in a twin-screw machine to melt, extrude and granulate. The process conditions are: twin-screw first stage temperature 160-170°C, second-stage temperature 170-180°C, third-stage temperature 180-190°C, main screw speed 100-300 rev / min, feeding screw speed 20-45 rev / min.

Embodiment 2

[0044] Dissolve 1% maleic anhydride, 1% odorless initiator, and 1% antioxidant into 1% styrene liquid, pre-mix for 3 minutes in a high-speed batch mixer, then add baked 96% ABS to high-speed Ingredients in a blender, then blend together for 5 minutes and set aside. Put the stirred mixture in a twin-screw machine to melt, extrude and granulate. The process conditions are: twin-screw first stage temperature 160-170°C, second-stage temperature 170-180°C, third-stage temperature 180-190°C, main screw speed 100-300 rev / min, feeding screw speed 20-45 rev / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Relative density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com