Laser anti-counterfeit texture label and manufacturing method thereof

A laser anti-counterfeiting and production method technology, which is applied in the production of special varieties of printed matter, record carriers used by machines, printing, etc., can solve the problems of complex processes, limited laser image layout or pattern, and no anti-counterfeiting ability in the form of coverage. Achieve the effect of difficult replication, high security, and guaranteed uniqueness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

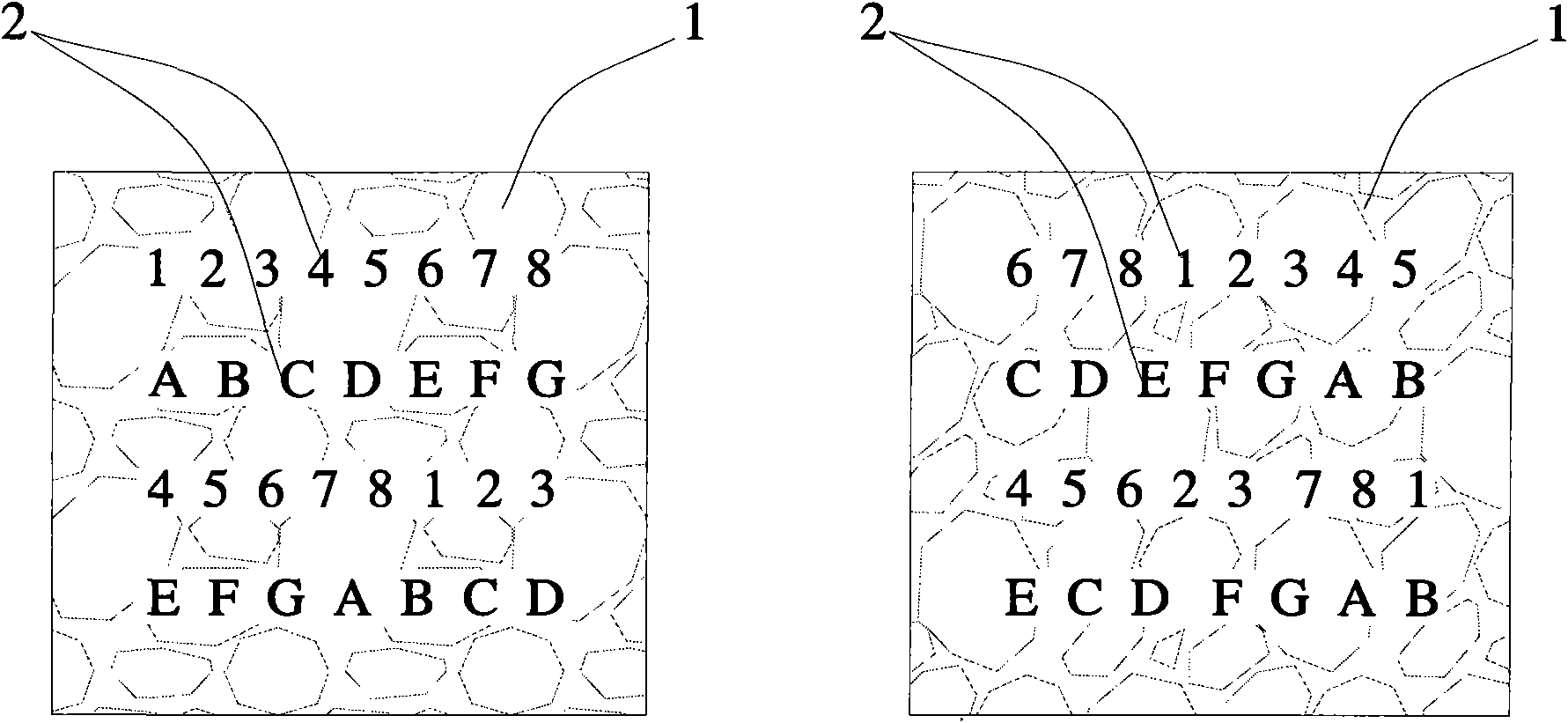

[0022] Such as figure 1 The two laser anti-counterfeiting texture label units shown in the figure realize anti-counterfeiting by forming a hollowed-out unit graphic 2 with laser holographic effect and dissimilarity on the texture base layer 1. The unit graphic 2 of the left and right texture label units in the figure is Totally different and laser-like. Manufacturers who make labels can freely print graphics with laser effects through the printer, which overcomes the defect that the previous laser printing can only be repeated printing after plate making. Produce variable graphics with laser holographic effects through ordinary technology, or the cost is not allowed, so as to achieve the purpose of anti-counterfeiting. Of course, the textured base layer 1 of the present invention also has an anti-counterfeiting effect, and through different combinations of textures, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com