Three-product sealed spiral dense medium separator

A dense medium, three-product technology, applied in the direction of solid separation, wet separation, chemical instruments and methods, etc., can solve the problem that the cyclone cannot really realize the three-product separation, etc., and achieve light weight, discharge specification, and process Simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

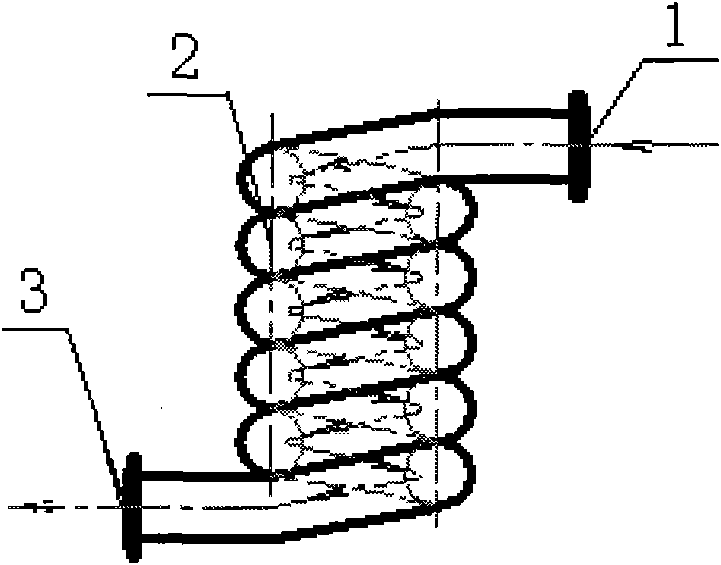

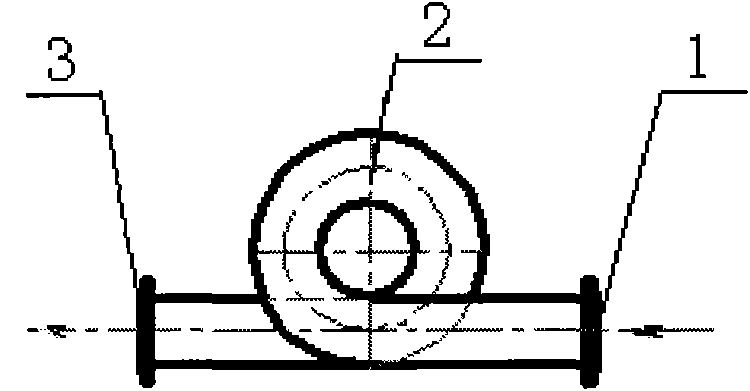

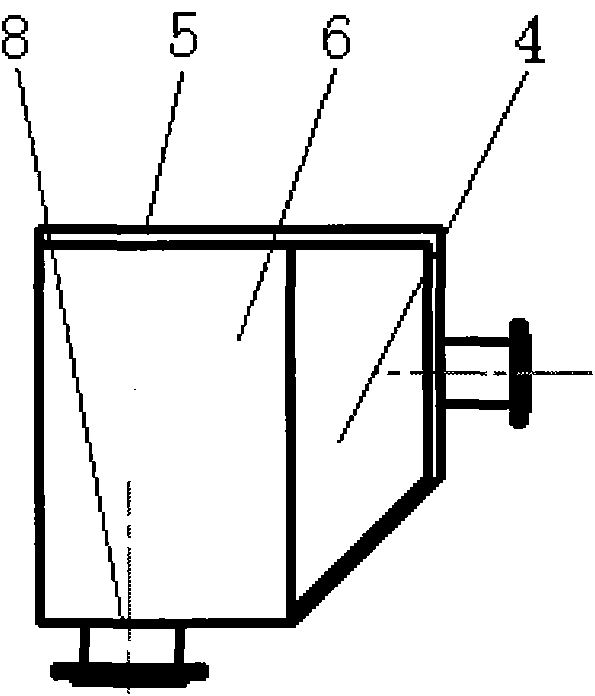

[0022] Accompanying drawing is a kind of specific embodiment of the present invention. This embodiment comprises the sealing spiral tube 2 that is provided with material inlet 1 and material outlet 3, and the divider 5 that inlet communicates with material outlet 3, divider 5 interior is divided into three parts by two pieces of product dividing plate 6, two The front ends of the product partitions 6 are hinged with the dividing knife 4 at the entrance of the divider 5, and the dividing knife 4 is erected on the adjusting screw 7; the bottom ends of the three divided parts of the divider 5 are all provided with a product that communicates with the product collection chamber. Exit 8; The angle that described dividing knife 4 deviates from heavy vertical line satisfies a=arctg (g / (u 2 / r))=arctg(gr / u 2 ), where a is the deflection angle of the splitting knife 4, g is the local acceleration of gravity, u is the linear velocity of the medium flow, and r is the radius of gyration ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com