Strain tower with shape like Chinese character 'gan' of compact transmission line

A transmission line and dry-shaped technology, applied in the direction of towers, electrical components, building types, etc., can solve the problems of low air gap of the lower phase jumper, large amount of tree felling, insufficient clearance of supports, etc., and achieve a small amount of earth and stone extraction , reduce tree felling, economically reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following describes the implementation of the present invention in detail with reference to the accompanying drawings, but they do not constitute a limitation to the present invention, and are merely examples. At the same time, the advantages of the present invention will become clearer and easier to understand.

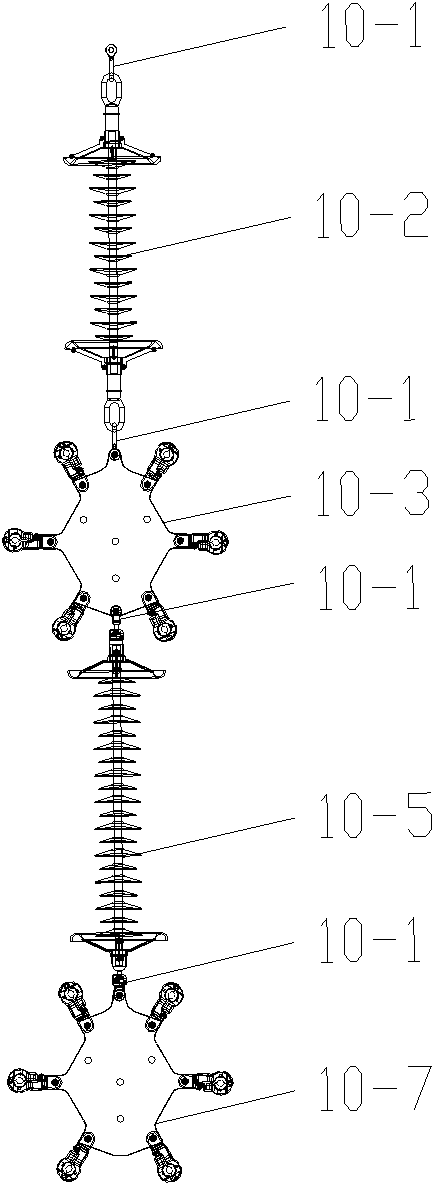

[0026] With reference to the attached drawings, it can be seen that the compact transmission line trunk-shaped tension tower of the present invention includes tower legs 8, tower body 7, tower head 13, conductor tension string 11, ordinary jumper suspension string 9 and combined jumper suspension string 10. The upper end of the tower head 13 is provided with a ground wire bracket and a joint jumper wire bracket 3. The ground wire bracket includes an outer corner side ground wire bracket 1 and an inner corner side ground wire bracket 2, and the inner corner side ground wire bracket 2 is located at the outer corner Between the side ground wire bracket 1 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com