Solar device and manufacturing method thereof

A solar energy device and solar energy technology, applied in photovoltaic power generation, electrical components, circuits, etc., can solve the problems of low heat dissipation efficiency of solar cell structure, unsatisfactory metal heat dissipation effect, and high cost of heat dissipation device, and achieve good heat dissipation effect and low cost. , the effect of good thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings.

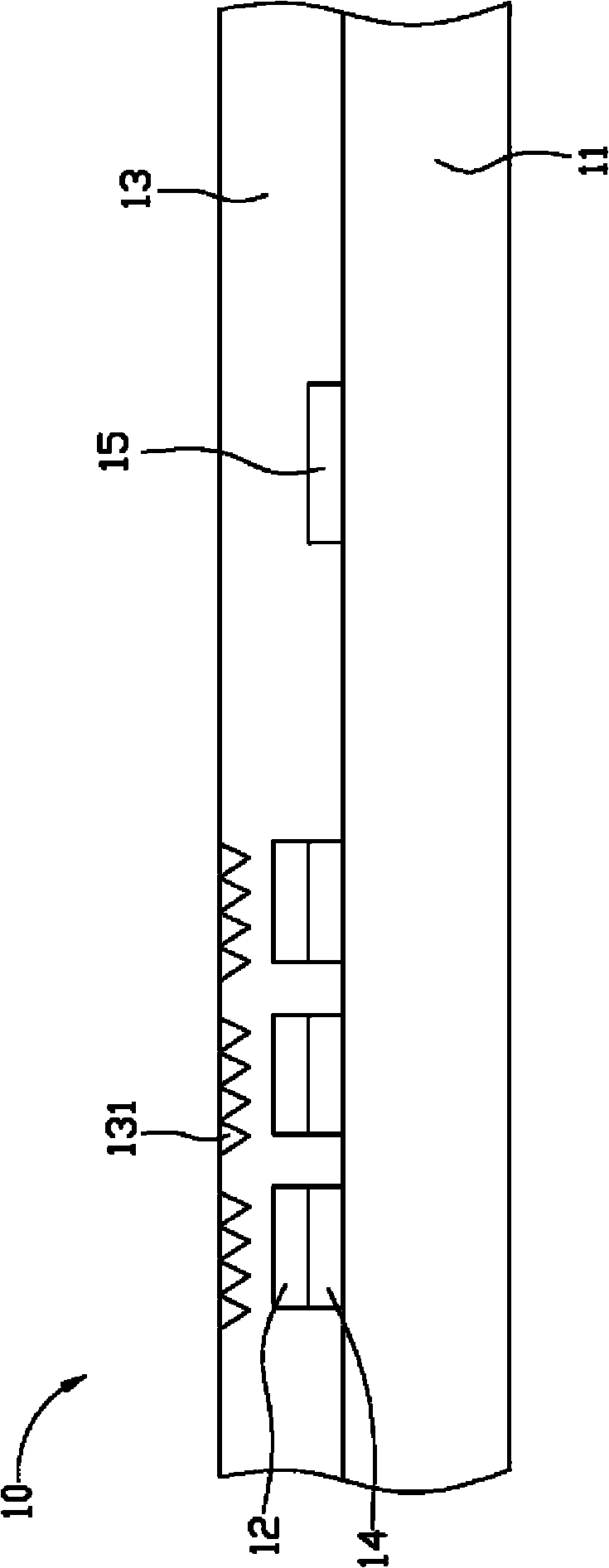

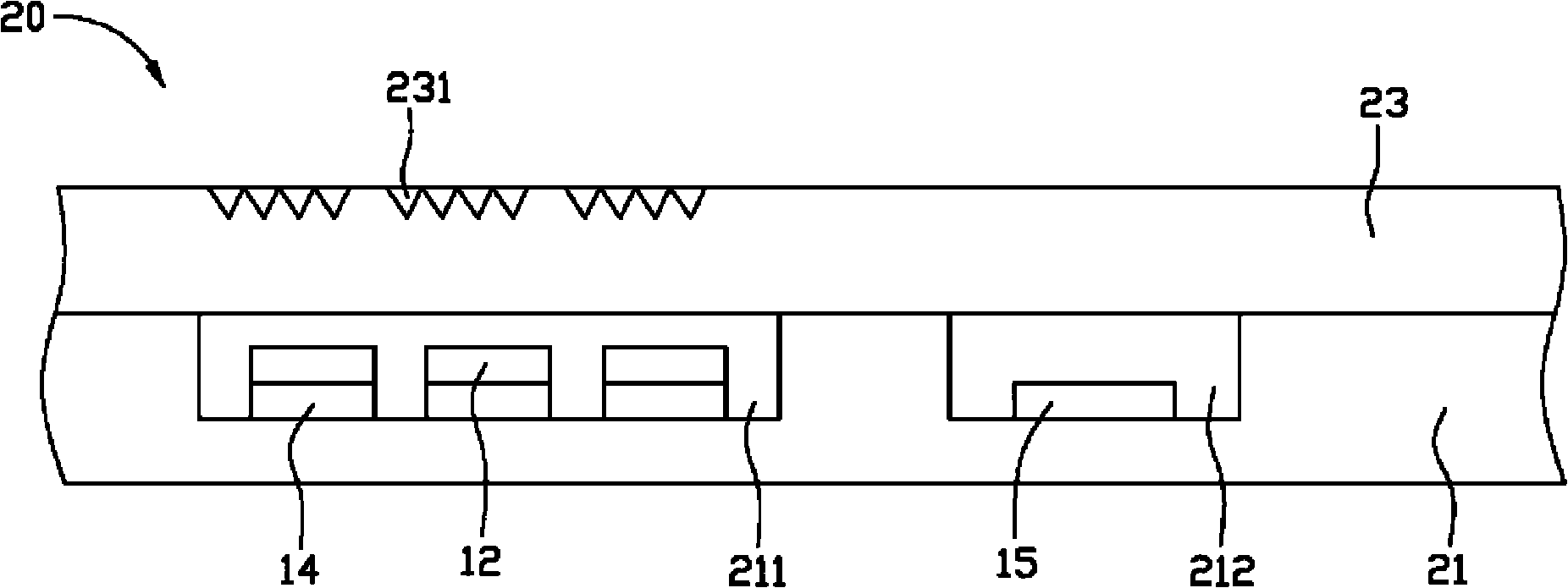

[0013] see figure 1 As shown, the solar device 10 according to the first embodiment of the present invention includes a ceramic substrate 11 , several III-V solar chips 12 , a packaging body 13 , an adhesive layer 14 and a circuit unit 15 .

[0014] The area of each III-V group solar chip 12 is greater than or equal to 1 square millimeter (mm 2 ) and less than or equal to 9 square millimeters, which are electrically connected to the circuit unit 15 and arranged on the ceramic substrate 11 in an appropriate manner to receive sunlight and convert sunlight into electrical energy output, for example, the III-V solar chip 12 utilizes an adhesive layer 14 is fixed on the ceramic substrate 11.

[0015] Preferably, an array of III-V group solar chips 12 is disposed on a ceramic substrate 11 .

[0016] The III-V solar chip 12 may be a gallium nitride (GaN) solar ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com