Method for manufacturing acceleration pole for transmission electron microscope and ceramic rings thereof

A manufacturing method and transmission electron microscope technology, applied in the field of ceramic rings, can solve the problems of poor compactness, loose texture of ceramic rings, and failure to meet pressure resistance requirements, and achieve sufficient glass phase migration, neat grain arrangement, and metallization. high intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

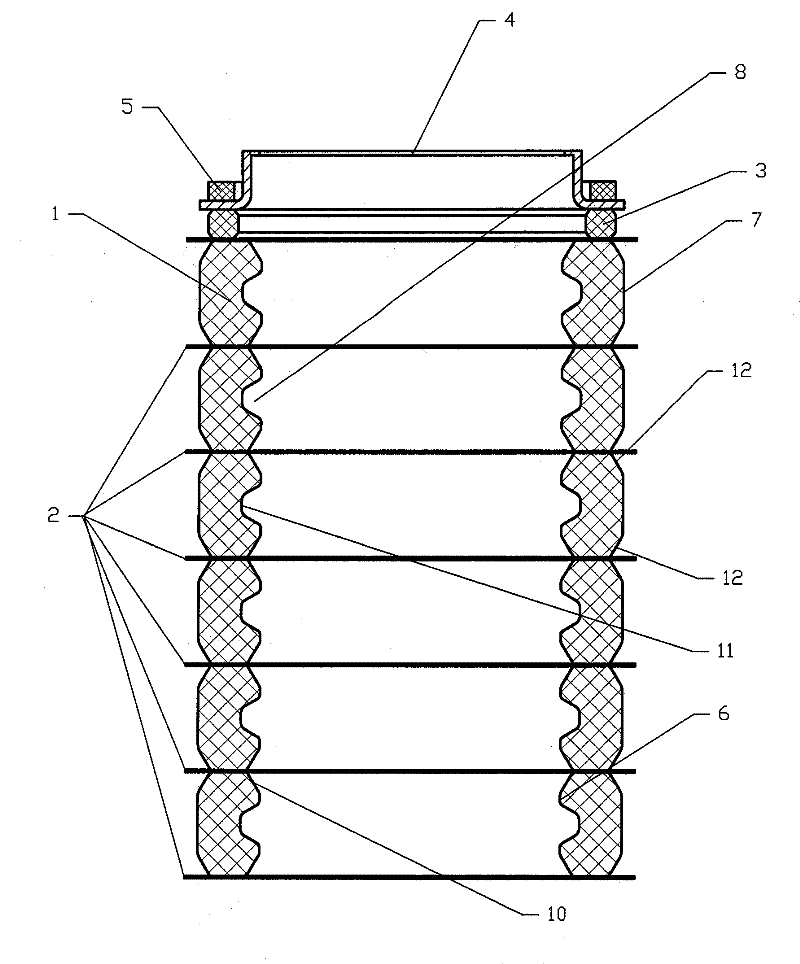

[0031] Such as figure 1 Shown is a schematic diagram of the preferred accelerating pole of the present invention for transmission electron microscopy, and the manufacturing method of the accelerating pole provided by the present invention comprises the following steps:

[0032] ①Ceramic ring forming, adopting an isostatic pressing forming process, so that the ceramic powder is formed into a hollow cylindrical ceramic ring 1, and the ceramic powder described in this embodiment is ceramic powder with an alumina content of 95%;

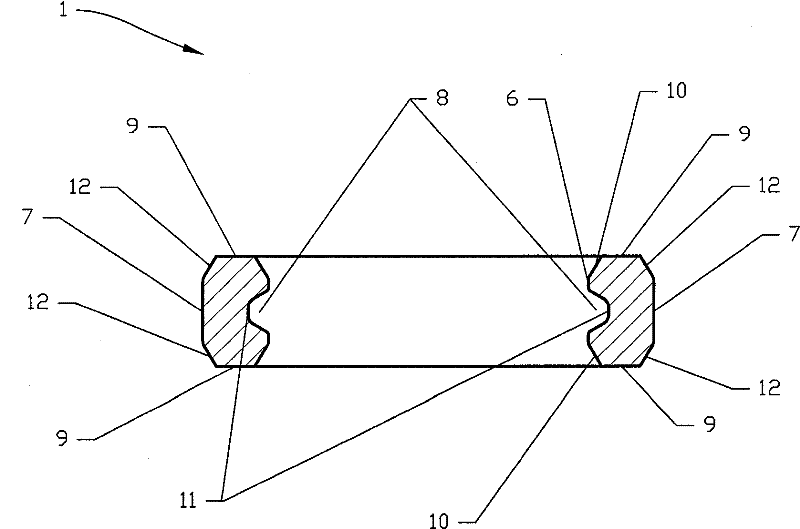

[0033] ② metallization, using thick film process to metallize the formed ceramic ring 1, first coating metallization paste on the two end faces 9 of the ceramic ring 1, and then using thick film process to metallize the ceramic ring 1 The ceramic ring 1 is metallized;

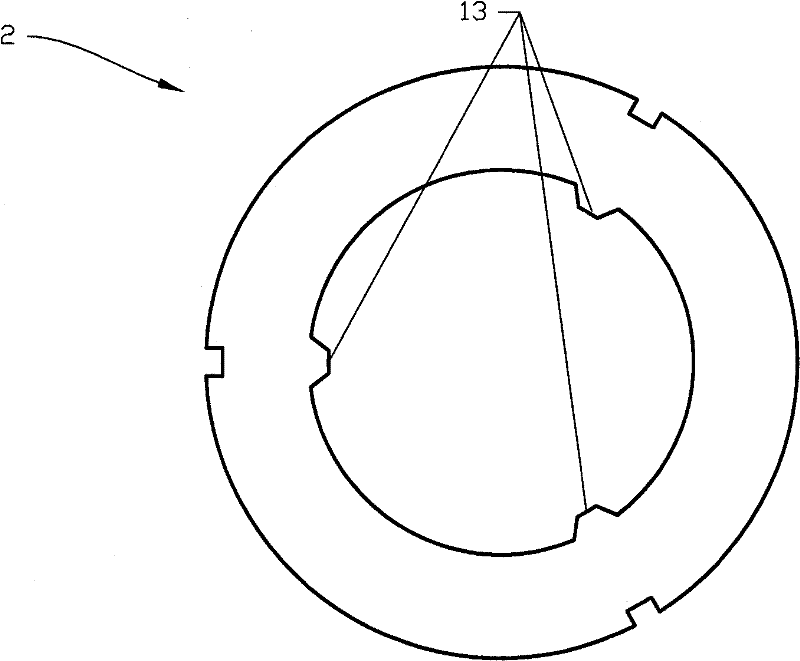

[0034] ③ Assembling, the n metallized ceramic rings 1 and n+1 annular sealing metal sheets 2 are fixedly assembled together with the coaxial center and at intervals, and the sealing at o...

Embodiment 2

[0038] In this embodiment, the outer structure of the ceramic ring 1 is completely the same as that in the first embodiment. The manufacturing method of the accelerating pole described in this embodiment includes the following steps:

[0039] a, ceramic ring forming, using isostatic pressing forming process, ceramic powder is formed into a hollow cylindrical ceramic ring 1, in the present embodiment, the pressure used in isostatic pressing forming process is 150-350MPa, preferably 200MPa, so Described ceramic powder selects the ceramic powder that aluminum oxide content is 95%;

[0040] b. Cleaning and firing, cleaning and then firing the shaped ceramic ring 1 to make the ceramic ring 1 harder and easier to grind and form according to the size requirements;

[0041] c. Metallization. The formed ceramic ring 1 is metallized by using a thick film process. In this embodiment, the thick film process molybdenum-manganese method is preferably used. First, two end faces 9 of the cer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com