Bridge prefabricated foundation and bed-burying method thereof

A foundation and bridge technology, applied in the field of buried bed construction technology, can solve the problems of less research in the field of bridge prefabrication foundation, and achieve the effects of saving temporary steel consumption, improving construction efficiency, and ensuring construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

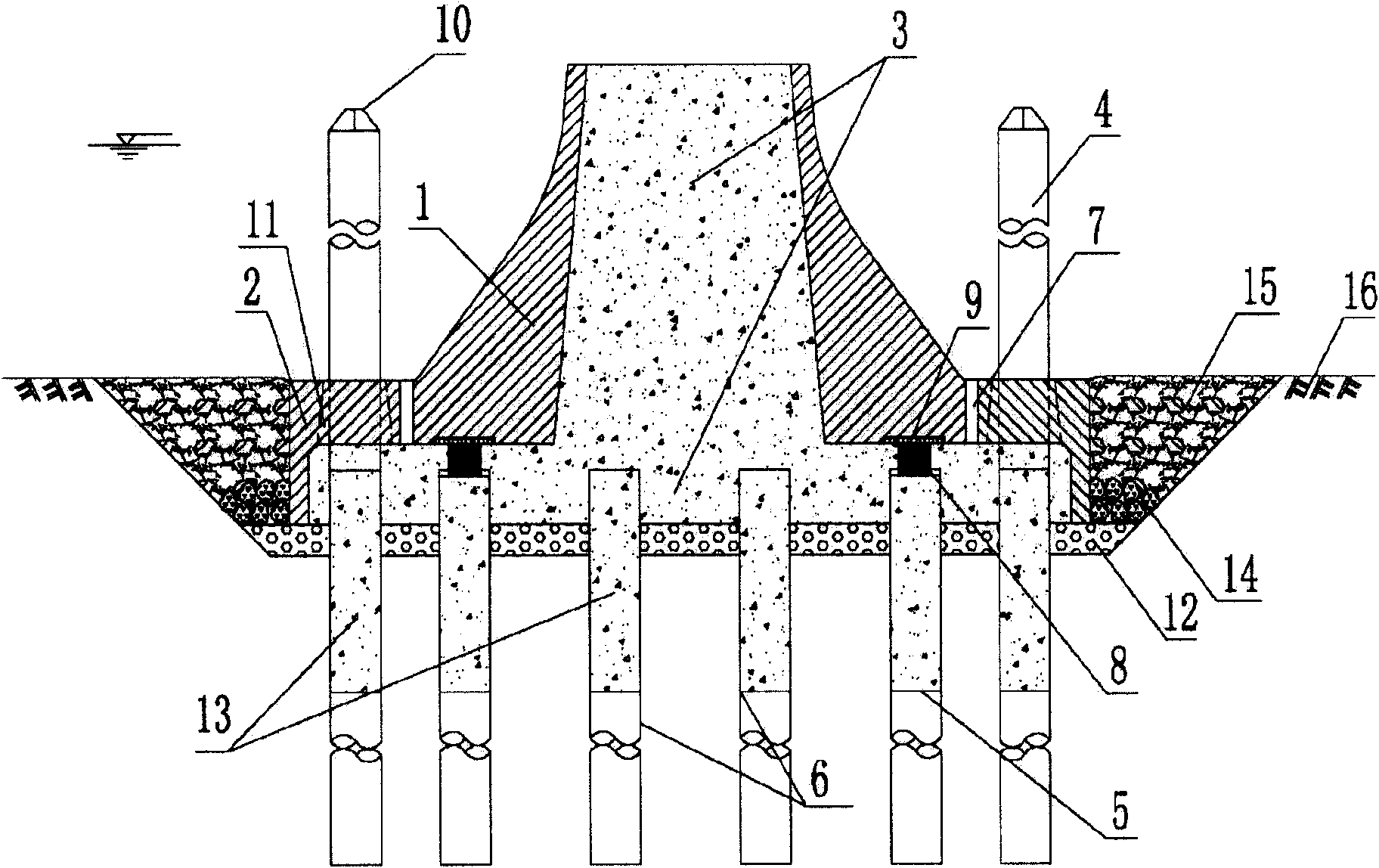

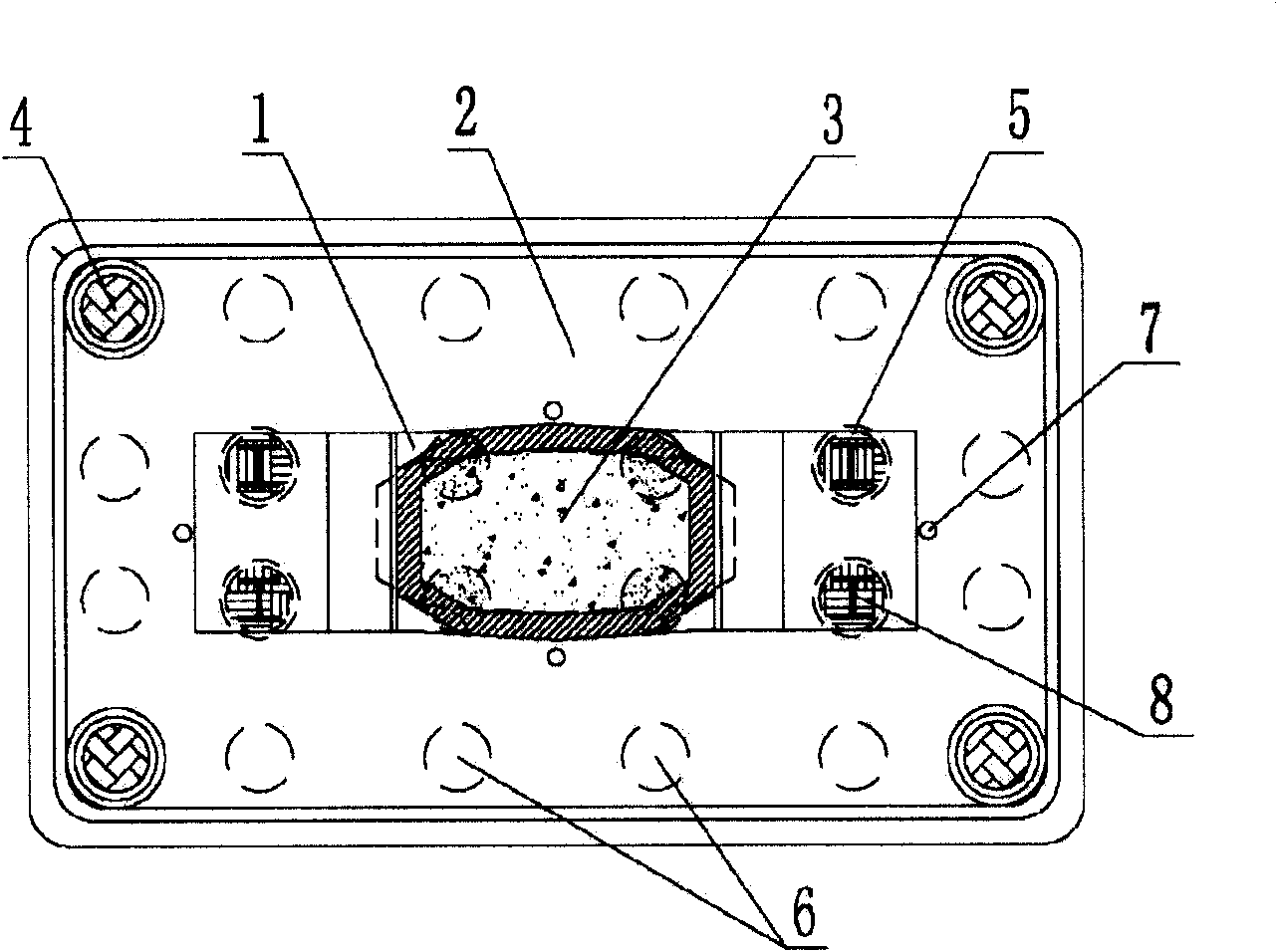

[0074] See figure 1 , 2 , Is a schematic diagram of the bridge prefabricated foundation structure of the present invention "a bridge prefabricated foundation and its buried bed method". In the picture, there are: lower bridge pier 1, cap 2, cavity 3, guide pile 4, supporting pile 5, bearing pile 6, exhaust gas refill hole 7, supporting pile positioning member 8, supporting pad 9 , Guide pile top guide positioning member 10, guide hole 11, anti-scouring cushion 12, pile core-filled concrete 13, plugging sandbag 14, riprap 15 and sea (or river, river) bed 16.

[0075] A prefabricated foundation for a bridge of the present invention, wherein the lower bridge pier 1 and the cap 2 are prefabricated as a single body; the cap 2 is an undercut structure with multiple guide holes 11 and multiple exhaust refill holes 7. Multiple support pads 9; multiple guide holes 11 are all placed on the periphery of the bearing platform 2, multiple support pads 9 are all placed on the periphery of the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com