Crystallizer copper tube mold water groove grooving process

A crystallizer copper tube and water tank technology, applied in manufacturing tools, other manufacturing equipment/tools, etc., can solve problems such as high cost and inability to mass-produce, and achieve the effects of improved efficiency, excellent heat conduction path, and increased heat exchange area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

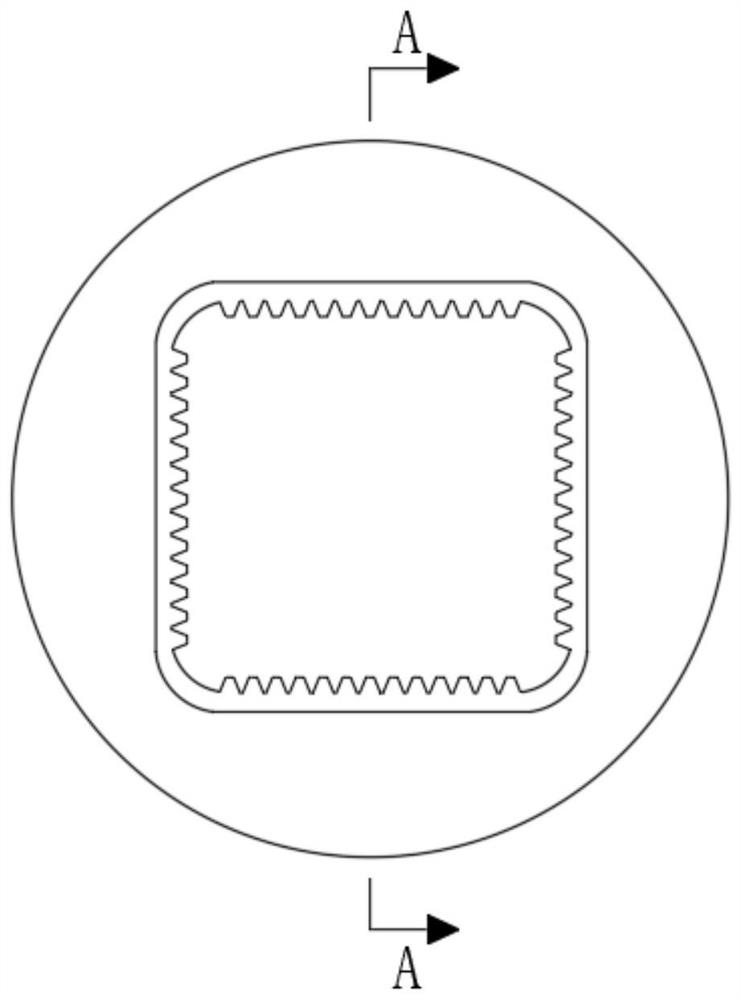

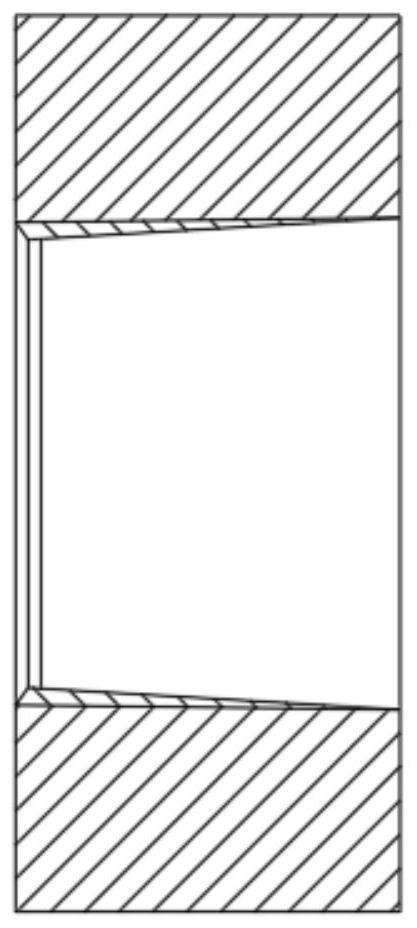

[0029] Such as figure 1 As shown in -5, the embodiment of the present invention provides a mold water tank process for copper tubes in crystallizers, including the following steps:

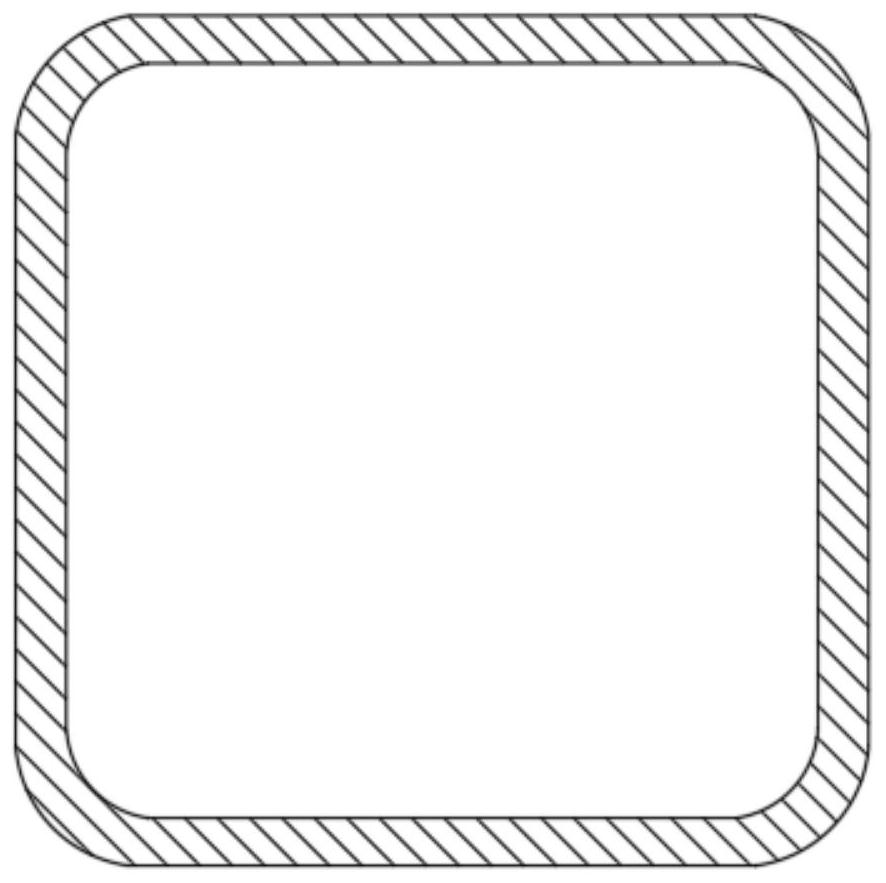

[0030] S1. Select the copper tube blank and use the metal flaw detector to detect the copper tube blank. The outer diameter of the copper tube blank is 190mm*190mm, the inner diameter is 154mm*154mm, and the wall thickness is 18mm;

[0031] S2. Prepare the copper tube blank mandrel, which is the inner mold. The size of the mandrel is 154mm*154mm*1200mm, and its radius R is 8000mm. Install the above-mentioned qualified copper tube blank on the inner mold;

[0032] S3. Prepare the slotting die for the copper tube blank. The working angle (opening degree) of the slotting die is 8°. During work, it is mainly formed by radial extrusion force, and the shape is stable. Special lubricating oil is coated on the slotting die. Applying lubricating oil can ensure that the copper tube blank passes through the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com