Complex bacteria inoculant for preparing organic fertilizer from effluents of animal slaughter houses and breeding plants serving as raw materials and preparation method thereof

A technology for slaughterhouses and inoculants, applied in the field of agricultural microbe applications, can solve the problems of not being able to meet the production requirements and the difficulty of achieving ideal results, and achieve the effects of promoting growth, improving plant disease resistance, and improving soil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] Embodiment 1: the preparation of two bacterium composite inoculants:

[0082] The formulations of the two bacteria are as follows:

[0083] A lactobacillus fermentum 50%

[0084] Bacillus laterosporus 50%

[0085] 1. Preparation of Lactobacillus fermentum fermentation broth A

[0086] Separated and stored, the seed medium is 1% glucose, 1% peptone, and 0.5% beef extract;

[0087] Production adopts deep static fermentation in fermenter;

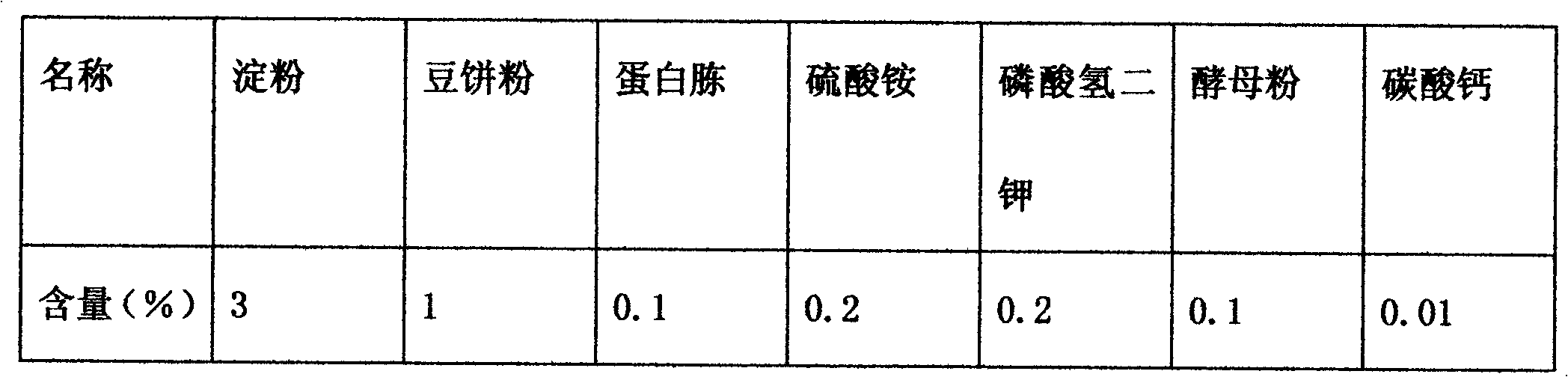

[0088] The general culture medium for lactic acid bacteria using the prior art: 3% soybean peptone, 2% yeast extract powder, 0.5% sodium acetate, compound trace element solution, compound vitamin solution;

[0089] The fermentation temperature is 40±2°C, and the fermentation time is 48 hours;

[0090] The obtained fermentation broth cfu≥2×10 8 pieces / ml.

[0091] 2. Preparation of single-bacteria fermentation broth B of Bacillus lateralis

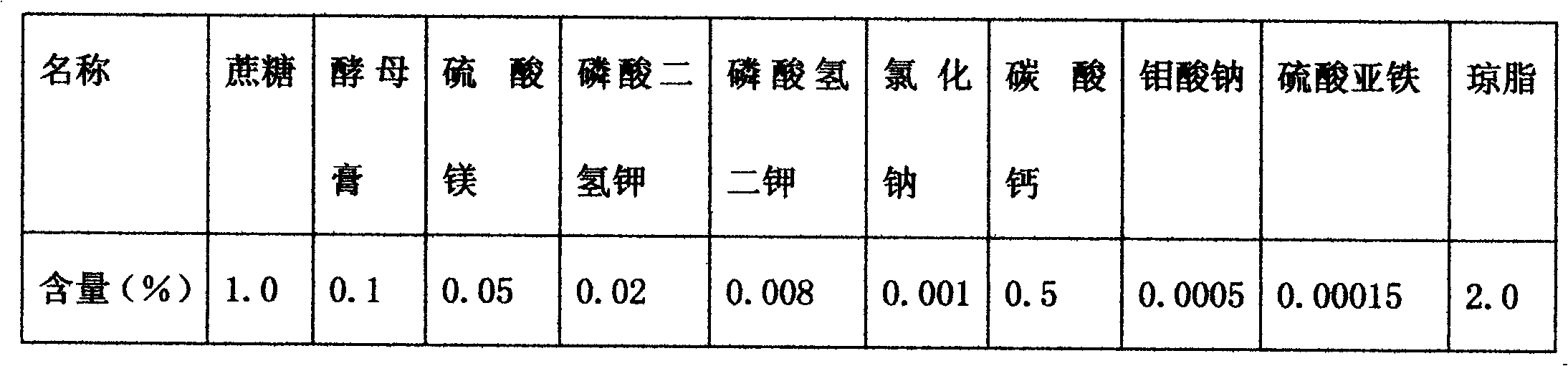

[0092] The medium formula is: 3.0% sucrose, 0.8% yeast extract, 1.2% peptone, MgSO 4 0.0...

Embodiment 2

[0101] Embodiment 2: by live bacteria (comprising live spore) quantity percentage content ratio is as follows in the final product:

[0102] A. Lactobacillus fermentum 20%

[0103] B. Bacillus laterosporus 20%

[0104] C, Corning Trichoderma T.koningii 20%

[0105] D. Bacillus azotofixans 20%

[0106] E. Bacillus mucilajginosus 20%

[0107] Completely follow the steps and methods in the implementation method, first obtain the bacterium liquid fermented separately by 5 strains, according to the content of live bacteria (including spores) actually measured in the fermentation liquid of each single strain, live bacteria according to the requirements of the aforementioned formula (spore) ratio, convert the mixed volume ratio of five kinds of bacterial strain fermentation broth, then mix and process into mixed liquid inoculant, concentrate, absorb, dry according to the technology in the embodiment, process into solid inoculant, in the final product The total bacterial content C...

Embodiment 3

[0110] Embodiment 3: by live bacterium (comprising living spore) quantity percentage content ratio is as follows in the final product:

[0111] A. Lactobacillus fermentum 35%

[0112] B. Bacillus laterosporus 35%

[0113] C. Trichoderma koningi T.koningii 10%

[0114] D. Bacillus azotofixans 10%

[0115] E. Bacillus mucilajginosus 10%

[0116] Completely follow the steps and methods in the implementation method to obtain 5 kinds of liquid inoculants respectively.

[0117] The above-mentioned inoculants were circulated and concentrated by using a 50,000-molecular-weight vacuum fiber membrane with a diameter of 18 cm and a length of 110 cm. Concentrate to 20% of original volume.

[0118] The high-temperature sterilized montmorillonite and rice husk powder are mixed and stirred at a ratio of 50% by weight each, and crushed to 80 meshes to form a carrier for dilution and adsorption.

[0119] The above-mentioned five kinds of concentrated liquid inoculants are respectively us...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com