Pu-erh tea extract, preparation method and application

A technology for Pu-erh tea and extract, applied in the field of Pu-erh tea extract, can solve the problems of low active ingredients and yield, large equipment demand, large alcohol consumption, etc., and achieves low cost, stable quality, and stable and controllable quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

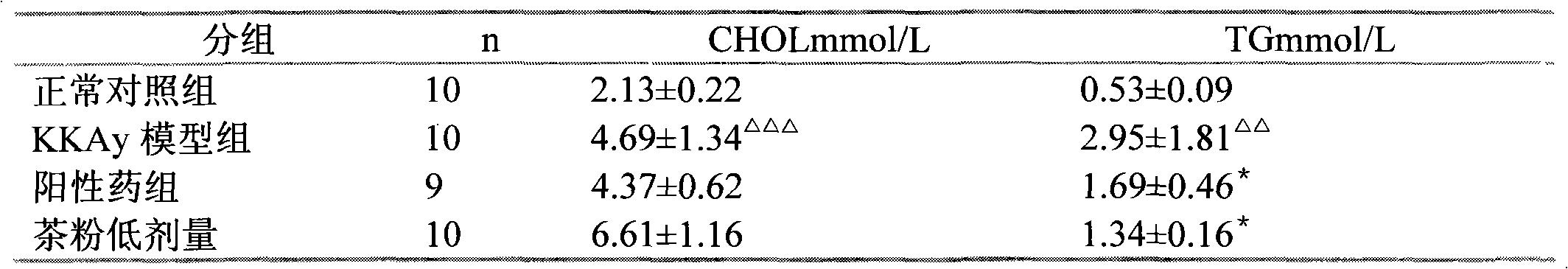

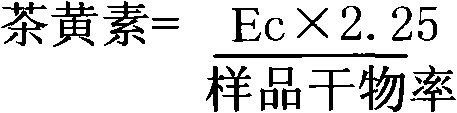

[0121] Pu’er tea, add water to vigorously boil and decoct to extract 3 times, decoct for 3 hours, add water to a total multiple of 26 times, filter the extract with 80 mesh, and concentrate the filtrate under reduced pressure to tea leaves with a temperature of ≤70°C (weight):concentrate (volume)= 1:1, centrifuge the concentrated liquid in a three-legged centrifuge, add 8 times the amount of ethanol to the centrifuged liquid, stir and extract twice, the extraction time is 1 hour, filter, and dry the filter cake with hot air. The yield of the extract is 20%. After content determination, the Pu’er tea extract contains 29.20% tea polyphenols, 22.70% theabrownin, 0.17% caffeine, 39.50% tea polysaccharide, 0.17% theaflavin, protein pectin Other impurities 8.26%.

Embodiment 2

[0123] Pu’er tea, add water to vigorously boil and decoct to extract 4 times, decoct for 2 hours, add water to a total multiple of 5 times, filter the extract with 40 mesh, and concentrate the filtrate under reduced pressure at a temperature of ≤70°C to tea leaves (weight):concentrate (volume)= 1:3, centrifuge the concentrated liquid in a three-legged centrifuge, add 3 times the amount of methanol to the centrifuged liquid, stir and extract twice, the extraction time is 0.5h, filter, and vacuum-dry the filter cake. Wherein the extract yield is 18%. After content determination, the Pu'er tea extract contains 54.59% tea polyphenols, 12.05% theabrownin, 0.3% caffeine, 24.48% tea polysaccharides, 0.05% theaflavins, and 8.53% impurities such as protein pectin.

Embodiment 3

[0125] Pu’er tea, add water to vigorously boil and decoct to extract 5 times, the decoction time is 0.5 hours, the total multiple of water is 18 times, the extract is filtered at 80 mesh, the filtrate temperature is ≤70°C and concentrated under reduced pressure to tea leaves (weight): concentrate (volume) = 1:0.5, centrifuge the concentrated liquid in a three-legged centrifuge, add 10 times the amount of propanol to the centrifuged liquid, stir and extract once, the extraction time is 0.5h, filter, and the filter cake is vacuum belt-dried. Wherein the extract yield is 17%. After content determination, the Pu'er tea extract contains 35.46% of tea polyphenols, 16.51% of theabrownin, 0.04% of caffeine, 46.05% of tea polysaccharides and 0.05% of theaflavins. , protein and pectin impurities etc. 1.89%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com