Driving oil way of variable valve mechanism with VVT and VVL system

A technology of valve mechanism and driving oil circuit, which is applied in the direction of machines/engines, mechanical equipment, engine components, etc., to achieve the effects of reducing direction change, shortening length, and shortening response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

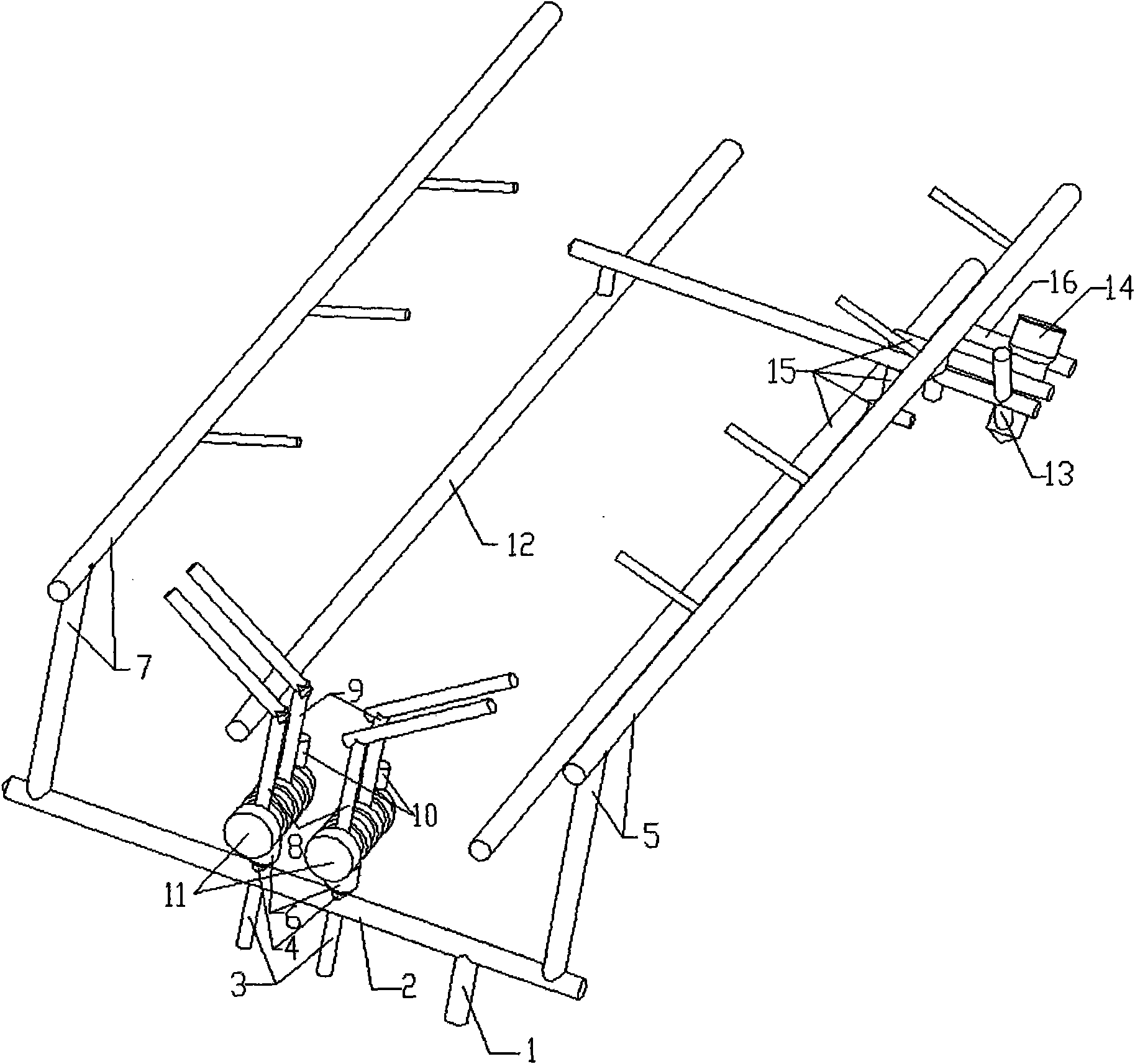

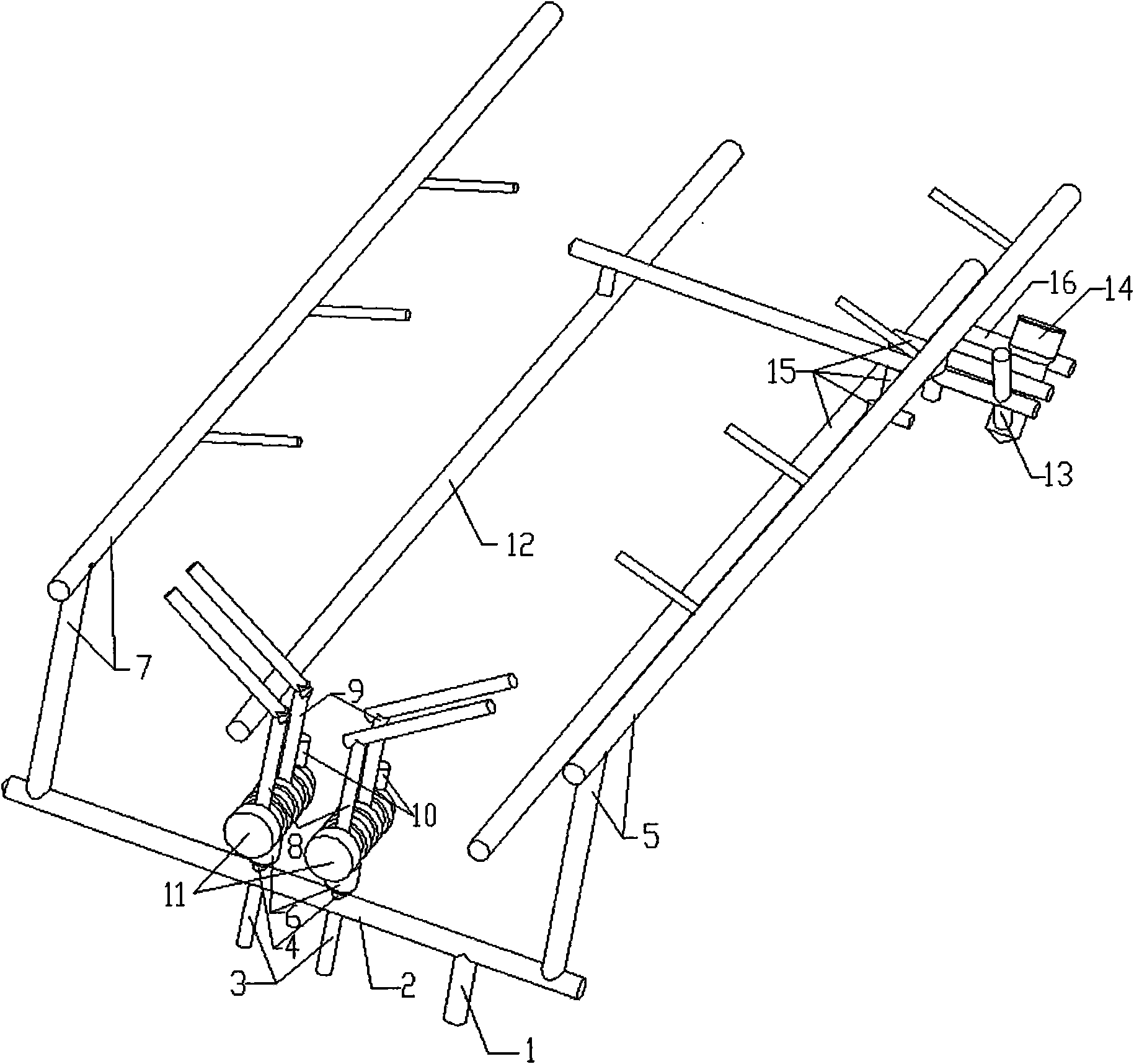

[0030] The present invention will be described in detail below according to the accompanying drawings, which is a preferred embodiment among various implementations of the present invention.

[0031] like figure 1 , as shown in Figure 2, a drive oil circuit of a variable valve mechanism with both VVT and VVL technologies, the engine oil flows through the main oil passage 1 of the cylinder block to the main oil passage 2 of the cylinder head, and then flows into the intake camshaft respectively Neck oil supply passage 5, VVT oil passage inlet 4, exhaust camshaft journal oil supply passage 7. The engine oil in the intake camshaft journal oil supply passage 5 further flows into the exhaust hydraulic lash adjuster oil passage 12 to control the oil passage inlet 13 by the VVL system. The VVT oil passage inlet 4 is arranged in the middle of the cylinder head, and a check valve 6 is installed in the VVT oil passage, and its installation position is between the VVT oil passage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com