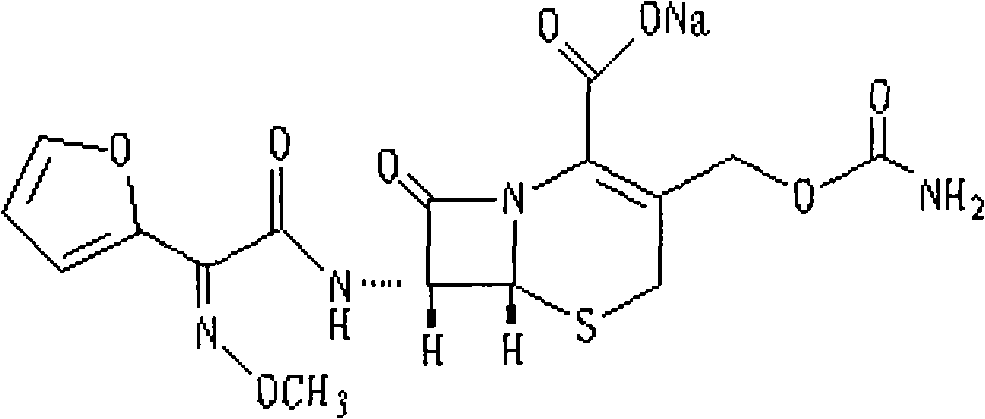

Preparation method of cefuroxime sodium

A technology of cefuroxime sodium and cefuroxime acid, which is applied in the fields of organic chemistry and antibacterial drugs, can solve the problems of slow dissolving speed of cefuroxime sodium, increase of impurities and side reactions, increase of stirring time, etc., and achieve clinical benefit The effect of safe medication, convenient clinical use, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A preparation method of cefuroxime sodium, comprising the steps of:

[0028] In the first step, add 250ml of methanol, 39.5g of sodium isooctanoate and 50% sodium lactate aqueous solution containing 0.27g of sodium lactate into a three-necked bottle, and stir until the sodium isooctanoate is completely dissolved to obtain a sodium solution.

[0029] In the second step, add 400ml of acetone, 50ml of purified water and 50.9g of cefuroxime acid to another three-necked bottle, raise the temperature to 25-26°C, stir to completely dissolve the cefuroxime acid; then add 5g of activated carbon, stir to decolorize, Filter to obtain cefuroxime acid filtrate.

[0030] In the third step, slowly add the cefuroxime acid filtrate into the sodium solution at room temperature, stir to form a precipitate, stir for 30 minutes, and filter to obtain a wet product of cefuroxime sodium.

[0031] In the fourth step, the wet product of cefuroxime sodium was washed twice with a mixture of 200ml...

Embodiment 2

[0034] A preparation method of cefuroxime sodium, comprising the steps of:

[0035] In the first step, add 200ml of absolute ethanol, 0.53g of sodium isooctanoate and 70% sodium lactate aqueous solution containing 35.5g of sodium lactate into a three-necked bottle, and stir until the sodium isooctanoate is completely dissolved to obtain a sodium solution.

[0036] In the second step, add 270ml of acetone, 30ml of purified water and 135.8g of cefuroxime acid to another three-necked bottle, raise the temperature to 34-35°C, and stir to completely dissolve the cefuroxime acid; then add 8g of activated carbon, stir to decolorize, Filter to obtain cefuroxime acid filtrate.

[0037] In the third step, the temperature of the sodium solution is controlled at 28-30° C., and the cefuroxime acid filtrate is slowly added to the sodium solution, stirred to form a precipitate, stirred for 45 minutes, and filtered to obtain a wet product of cefuroxime sodium.

[0038] In the fourth step, th...

Embodiment 3

[0041] A preparation method of cefuroxime sodium, comprising the steps of:

[0042] In the first step, add 180ml of absolute ethanol, 14g of sodium isooctanoate and 70% sodium lactate aqueous solution containing 27g of sodium lactate into a three-necked bottle, and stir until the sodium isooctanoate is completely dissolved to obtain a sodium solution.

[0043] In the second step, add 240ml of acetone, 35ml of purified water and 38g of cefuroxime acid to another three-necked bottle, raise the temperature to 30-31°C, and stir to completely dissolve the cefuroxime acid; then add 5g of activated carbon, stir to decolorize, and filter , to obtain cefuroxime acid filtrate.

[0044] In the third step, the temperature of the sodium solution is controlled at 39-40°C, and the cefuroxime acid filtrate is slowly added to the sodium solution, stirred to form a precipitate, cooled to room temperature while stirring, and filtered to obtain a wet product of cefuroxime sodium.

[0045] In the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com