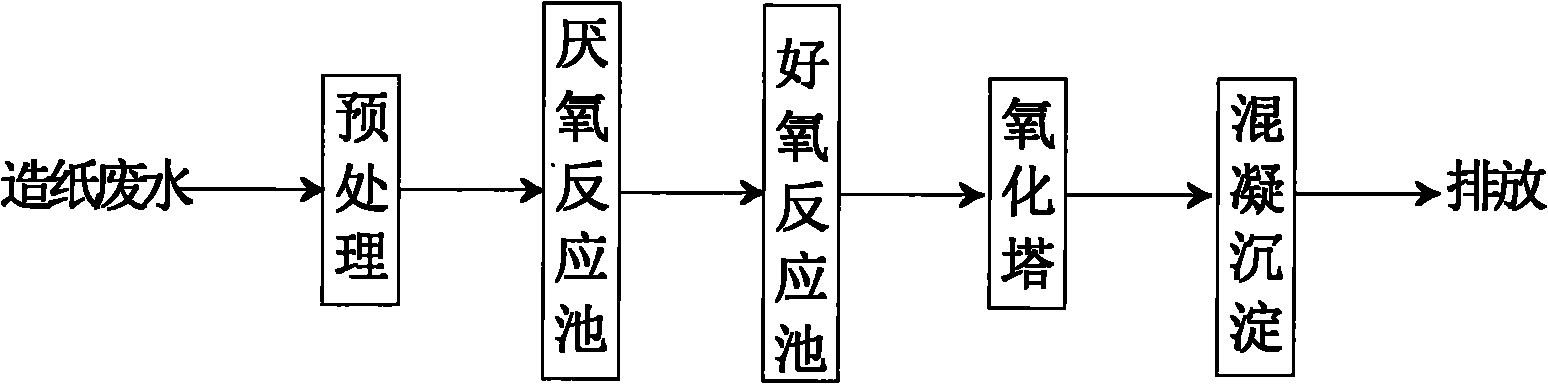

Combined process for treating papermaking waste water

A technology for papermaking wastewater and treatment process, which is applied in the process of wastewater treatment, water/sewage multi-stage treatment, oxidized water/sewage treatment, etc. The effect of reducing, good effluent quality and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The sewage of a papermaking enterprise enters the high-efficiency bioaugmentation tank after anaerobic treatment. COD is 464.4mg / L, NH3-N is 15.34mg / L, TN is 22.33mg / L, TP is 2.1mg / L, and the chromaticity is 260 times. The high-efficiency bio-enhanced pool adopts 100% external return and 300% internal return. The dosage of powdered activated carbon is 50mg / L. The residence time is 20h. The aeration air supply is provided according to the air-to-water ratio of 20:1. The effluent quality COD is 104.3mg / L, NH3-N is 1.34mg / L, TN is 9.6mg / L, TP is 0.8mg / L, and the chromaticity is 80 times.

Embodiment 2

[0027] Other operations are as in Example 1. But do not add powdered activated carbon. The effluent quality COD is 148.3mg / L, NH3-N is 3.34mg / L, TN is 12.6mg / L, TP is 1.2mg / L, and the chromaticity is 120 times.

Embodiment 3

[0029] Other operations are as in Example 1. The effluent quality COD is 154.4mg / L, NH3-N is 3.34mg / L, TN is 32.4mg / L, TP is 0.9mg / L, and the chromaticity is 80 times.

[0030] Example 3

[0031] Other operations are as in Example 1. But the internal reflux ratio is 200%. The effluent quality COD is 142.4mg / L, NH3-N is 2.34mg / L, TN is 28.4mg / L, TP is 1.2mg / L, and the chromaticity is 90 times.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com