Method for reducing discharge of oxidization raffinate

A technology of discharge and residual liquid, applied in chemical instruments and methods, inorganic chemistry, peroxides/peroxyhydrates/peroxyacids/superoxides/ozone oxides, etc. Affect the oxidation yield of hydrogenated liquid, increase the cost of sewage treatment, etc., to achieve the effect of improving the oxidation yield, overcoming the hidden dangers of safety production, and reducing the loss of sewage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

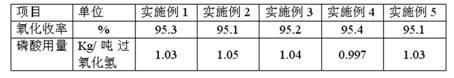

Embodiment 1

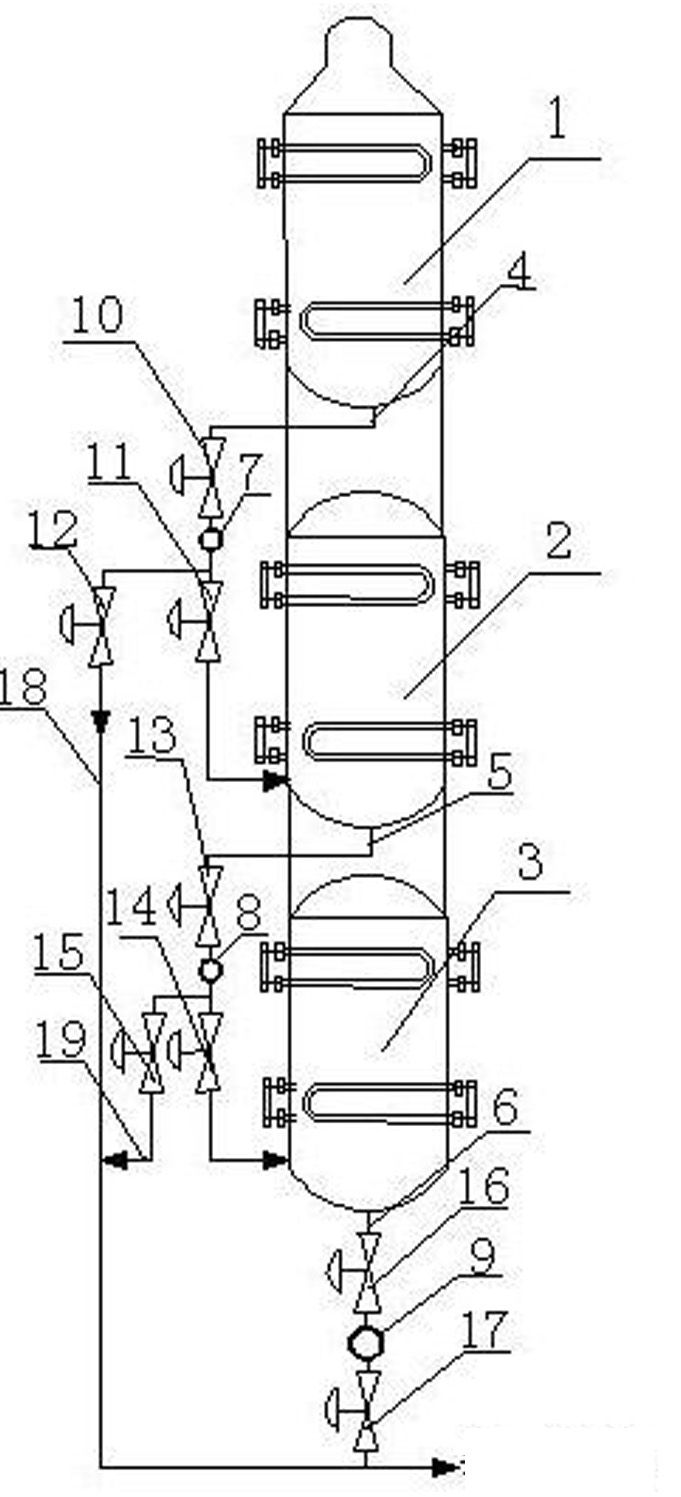

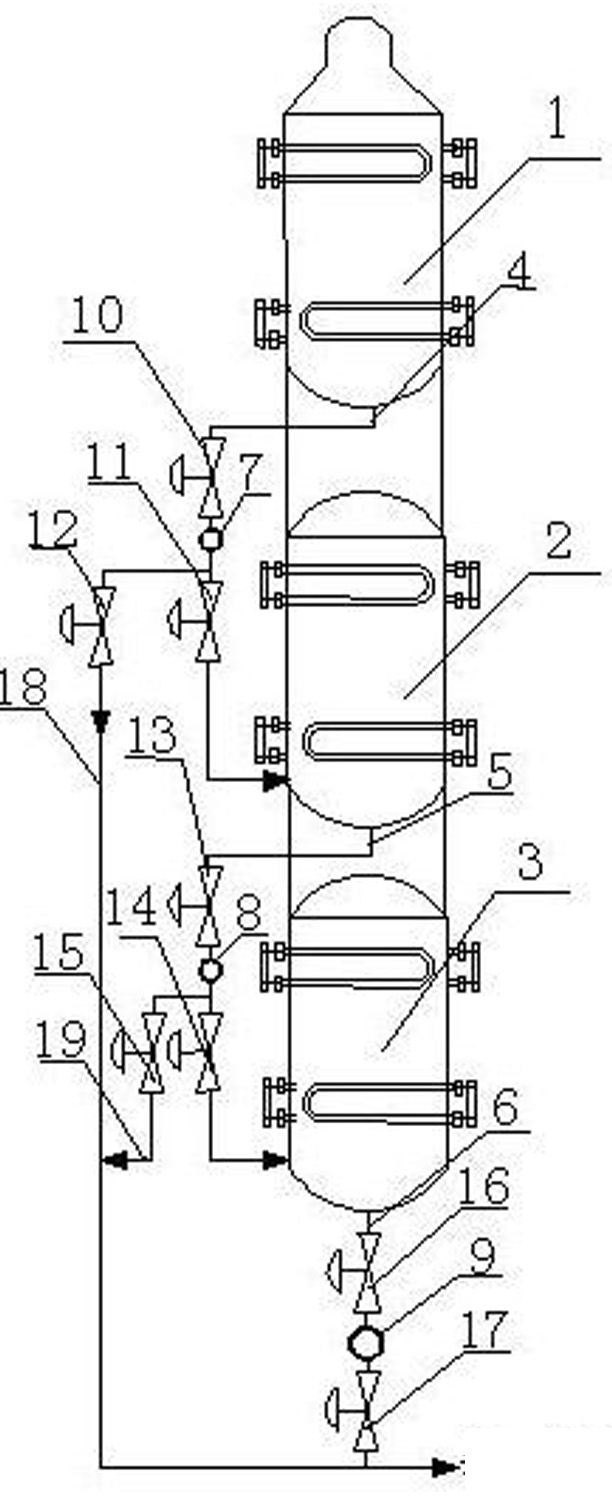

[0023] The oxidation raffinate at the bottom of the upper tower 1 of the oxidation tower is continuously discharged through the upper tower raffinate discharge pipe 4, and the discharged oxidation raffinate enters the bottom of the middle tower 2 and is mixed with the hydrogenated liquid and air entering the middle tower 2 Finally, participate in the chemical reaction in the middle section tower 2, and observe the quality of the oxidation raffinate discharged from the upper section tower raffinate discharge pipe 4 through the sight glass 7 to adjust the opening of the valve 10 and the valve 11, and the upper section tower 1 is oxidized The ratio of the volume of residual liquid discharge to the volume of hydrogenated liquid entering the tower is 1:200; the oxidized raffinate at the bottom of the middle-section tower 2 is continuously discharged through the middle-section tower raffinate discharge pipe 5, and the discharged oxidized raffinate enters the The bottom of the lower t...

Embodiment 2

[0025] The oxidation raffinate at the bottom of the upper section tower 1 of the oxidation tower is intermittently discharged through the upper section tower raffinate discharge pipe 4, and the quality of the oxidation raffinate discharged in the upper section tower raffinate discharge pipe 4 is observed through the sight glass 7 to determine Adjust the closing or opening of valve 10 and valve 11 and their opening degree, first discharge the water-phase substance in the oxidation raffinate from the upper section tower raffinate discharge pipe 4 into the middle section tower 2, and then pass the oxidation raffinate degradation product through The bypass discharge pipe 18 for the raffinate of the upper tower is discharged out of the oxidation tower, and the water-phase substance in the discharged oxidation raffinate enters the bottom of the middle tower 2, mixes with the hydrogenated liquid and air entering the middle tower 2, and is discharged in the middle tower Participate in...

Embodiment 3

[0027] The oxidation raffinate at the bottom of the upper tower 1 of the oxidation tower is continuously discharged through the upper tower raffinate discharge pipe 4, and the discharged oxidation raffinate enters the bottom of the middle tower 2 and is mixed with the hydrogenated liquid and air entering the middle tower 2 Finally, participate in the chemical reaction in the middle section tower 2, and observe the quality of the oxidation raffinate discharged from the upper section tower raffinate discharge pipe 4 through the sight glass 7 to adjust the opening of the valve 10 and the valve 11, and the upper section tower 1 is oxidized The volume ratio of the amount of raffinate discharge to the amount of hydrogenated liquid entering the section tower is 1:250; the oxidized raffinate at the bottom of the middle section tower 2 is intermittently discharged through the middle section tower raffinate discharge pipe 5, and observed through the sight glass 8 The quality of the oxida...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com