Dismounting device for fractured connecting rod

A technology for dismantling devices and connecting rods, which is applied in metal processing, metal processing equipment, manufacturing tools, etc. It can solve the problems of difficult to accurately control the size of the top pressure, difficulty in guaranteeing the breaking force, failure of connecting rods, etc., and achieves a simple structure Reliable, uniform and stable force, reducing the loss of particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

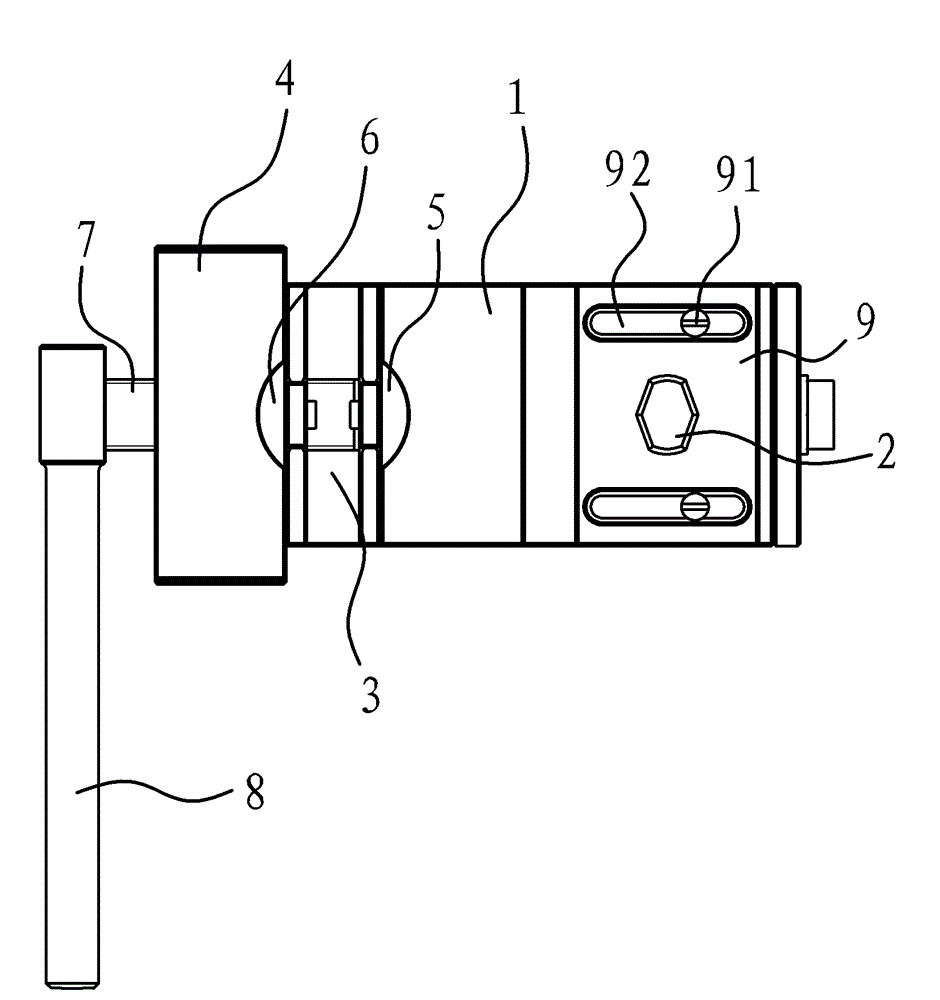

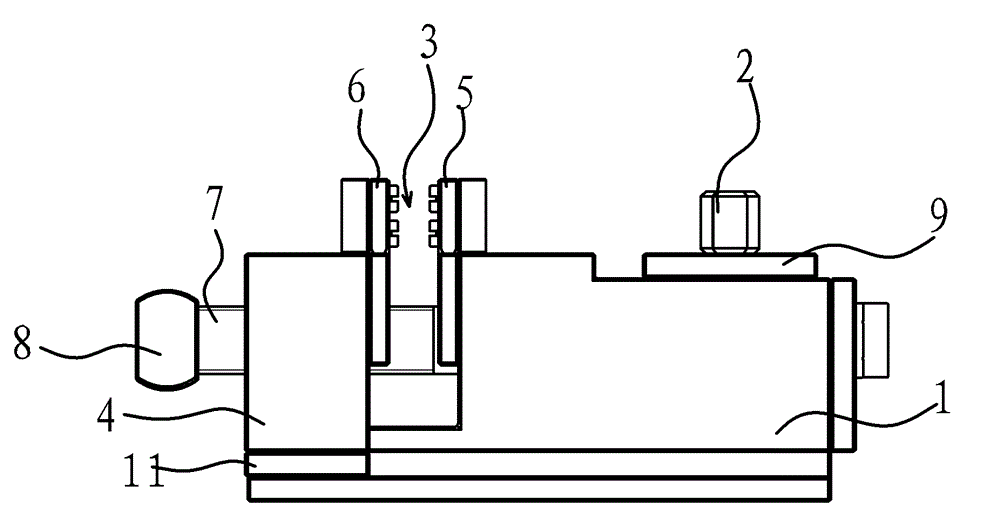

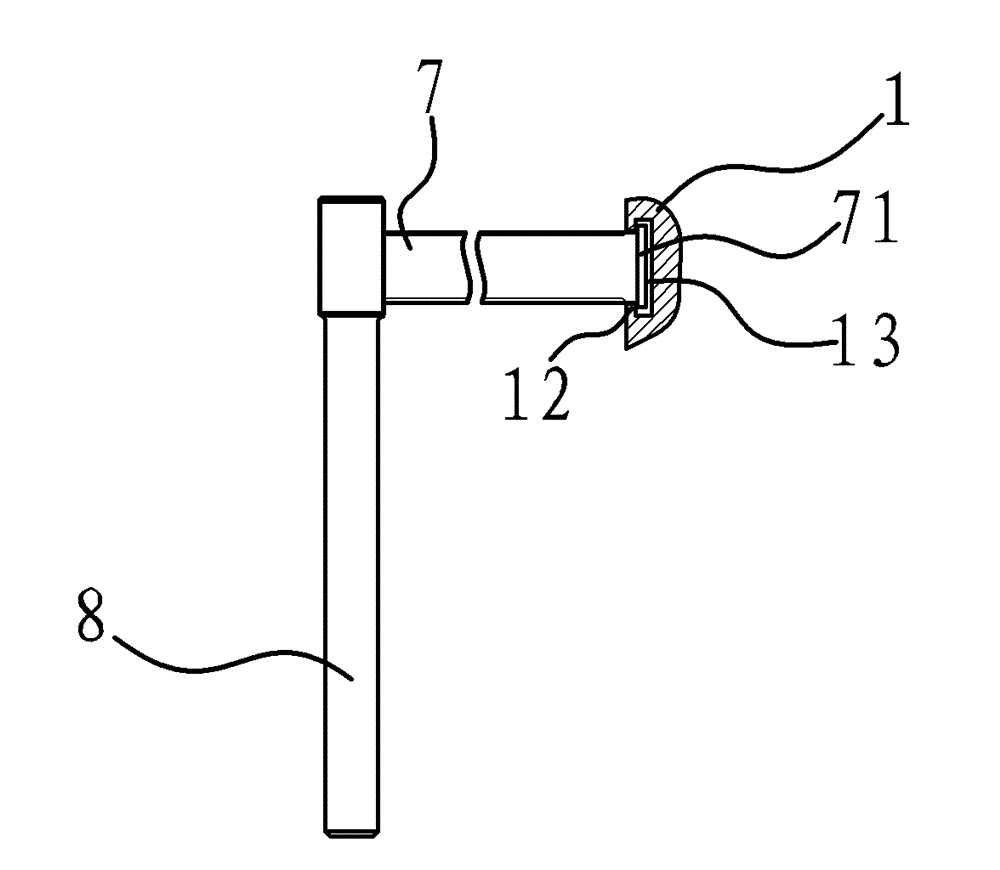

[0024] Such as figure 1 with figure 2 As shown, the dismantling device of the breakable connecting rod includes a base 1, and the base 1 is fixed with a positioning pin 2 for positioning the small end hole of the breakable connecting rod and a positioning piece 2 3 for positioning the big end hole of the breakable connecting rod. The base 1 also has a slider 4 that can slide thereon. The above-mentioned positioning member 2 3 is composed of a fixed half shaft 5 fixed on the base 1 and a movable half shaft 6 fixed on the slider 4. The base 1 There is a straight guide groove 11 on the top, and the slider 4 is connected to the straight guide groove 11 and can slide along the straight guide groove 11. The direction of exten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com