Titanium alloy rotor near-net manufacturing method

A manufacturing method, titanium alloy technology, applied in the field of powder metallurgy, to achieve the effect of high surface quality, simple process and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The steps of the near-net-shape manufacturing method of the titanium alloy rotor described in the present invention are as follows:

[0023] (a) Machining mandrel and sheath: using low-carbon steel, machining mandrel 3 and sheath 1 according to the titanium alloy rotor flow cavity to be prepared; considering the subsequent shrinkage and densification of titanium alloy powder, There must be a certain margin in the inner diameter and height.

[0024] (b) Preparation of titanium alloy spherical powder: use plasma rotating electrode to prepare titanium alloy spherical powder, wherein the diameter of the titanium electrode is Φ40mm, the rotation speed is 18000rpm, atomize to form titanium alloy spherical powder, sieve and collect the titanium alloy spherical powder with a particle size of 45-150 μm ;

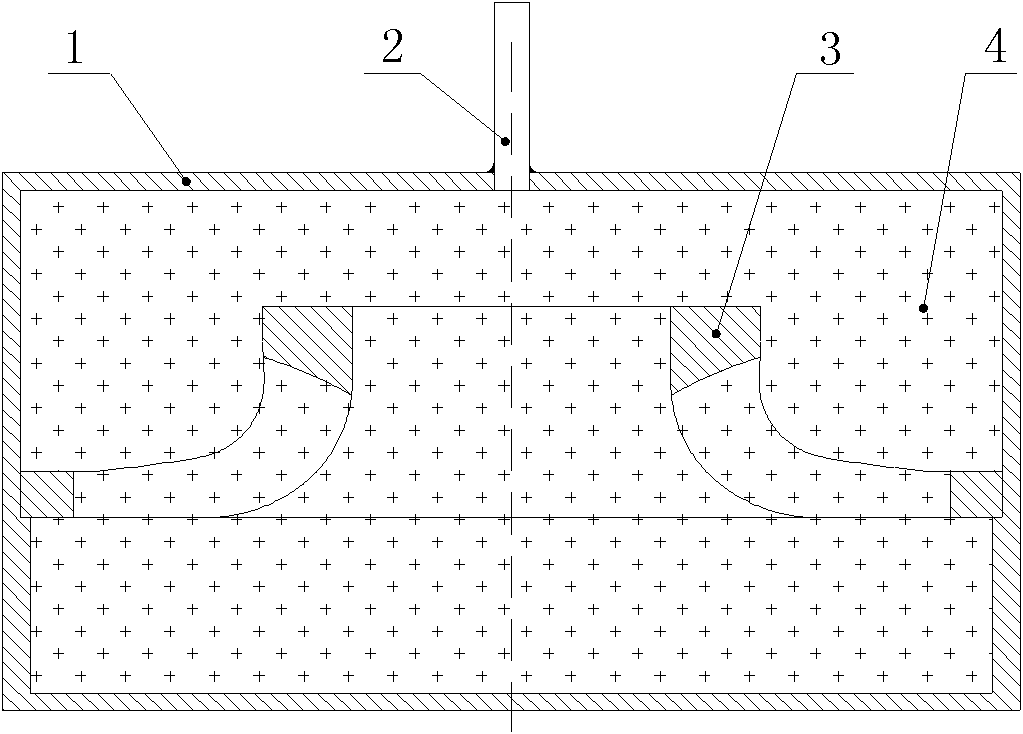

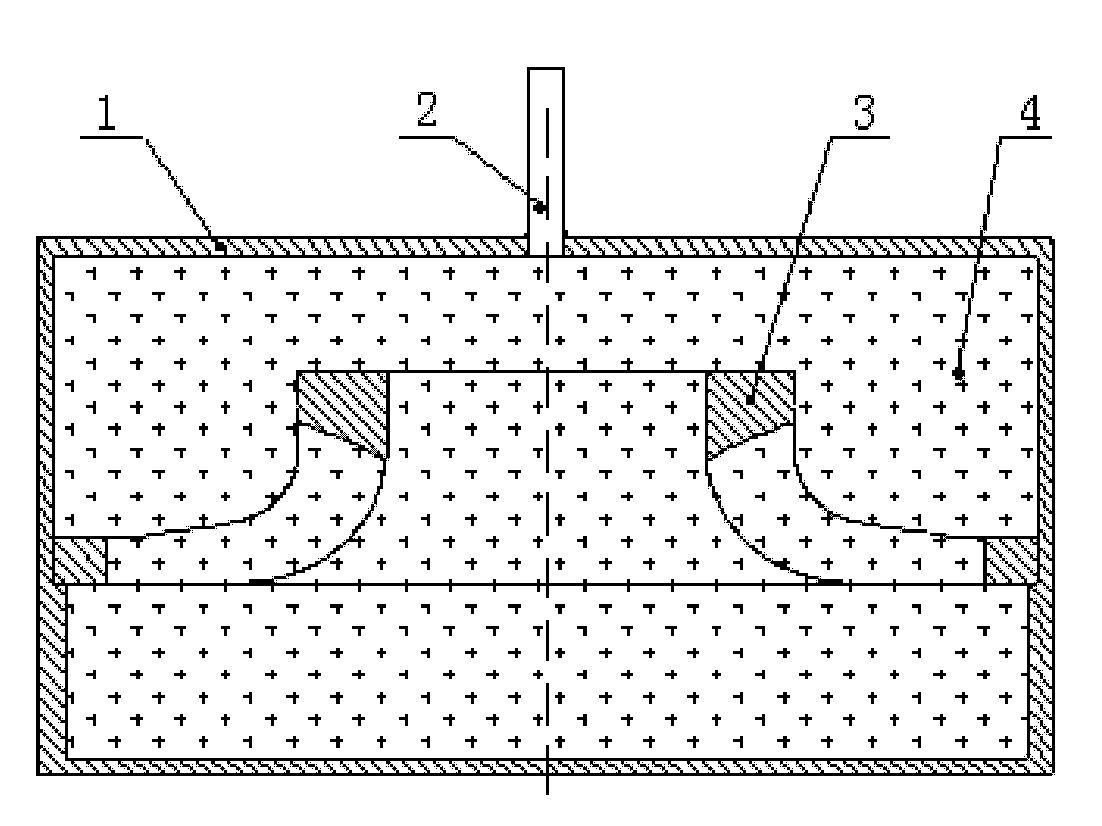

[0025] (c) Assembling the mandrel and filling powder, degassing: such as figure 1 As shown, the mandrel 3 is assembled into the sheath 1, and after being fixed, the titanium...

Embodiment 2

[0029] The steps of the near-net-shape manufacturing method of the titanium alloy rotor described in the present invention are as follows:

[0030] (a) Machining mandrel and sheath: using low carbon steel, machining mandrel 3 and sheath 1 according to the titanium alloy rotor flow channel to be prepared; considering the subsequent shrinkage and densification of titanium alloy powder, the inner diameter of sheath and height to leave a certain margin.

[0031] (b) Prepare titanium alloy spherical powder: prepare titanium alloy spherical powder by using a plasma rotating electrode, wherein the diameter of the titanium electrode is Φ60mm, the rotation speed is 13000rpm, atomize to form titanium alloy spherical powder, and sieve and collect titanium alloy spherical powder with a particle size of 45-150 μm ;

[0032] (c) Assembling the mandrel and filling powder, degassing: such as figure 1 As shown, the mandrel 3 is assembled into the sheath 1, and after being fixed, the titanium...

Embodiment 3

[0036] The steps of the near-net-shape manufacturing method of the titanium alloy rotor described in the present invention are as follows:

[0037] (a) Machining mandrel and sheath: using low carbon steel, machining mandrel 3 and sheath 1 according to the titanium alloy rotor flow channel to be prepared; considering the subsequent shrinkage and densification of titanium alloy powder, the inner diameter of sheath and height to leave a certain margin.

[0038] (b) Prepare titanium alloy spherical powder: prepare titanium alloy spherical powder by using plasma rotating electrode, wherein the diameter of the titanium electrode is Φ50mm, the rotation speed is 15000rpm, atomize to form titanium alloy spherical powder, sieve and collect titanium alloy spherical powder with a particle size of 45-150 μm ;

[0039] (c) Assembling the mandrel and filling powder, degassing: such as figure 1 As shown, the mandrel 3 is assembled into the sheath 1, and after being fixed, the titanium alloy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com