Carbon dioxide-absorbing device for anaesthesia machine

A carbon dioxide and absorption device technology, applied in respirator and other directions, can solve problems such as difficult detection, difficult to detect, and inability to accurately determine the installation position of the isolation diaphragm, so as to achieve uniform axial force and prevent installation from being in place.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described below in combination with specific embodiments and with reference to the accompanying drawings.

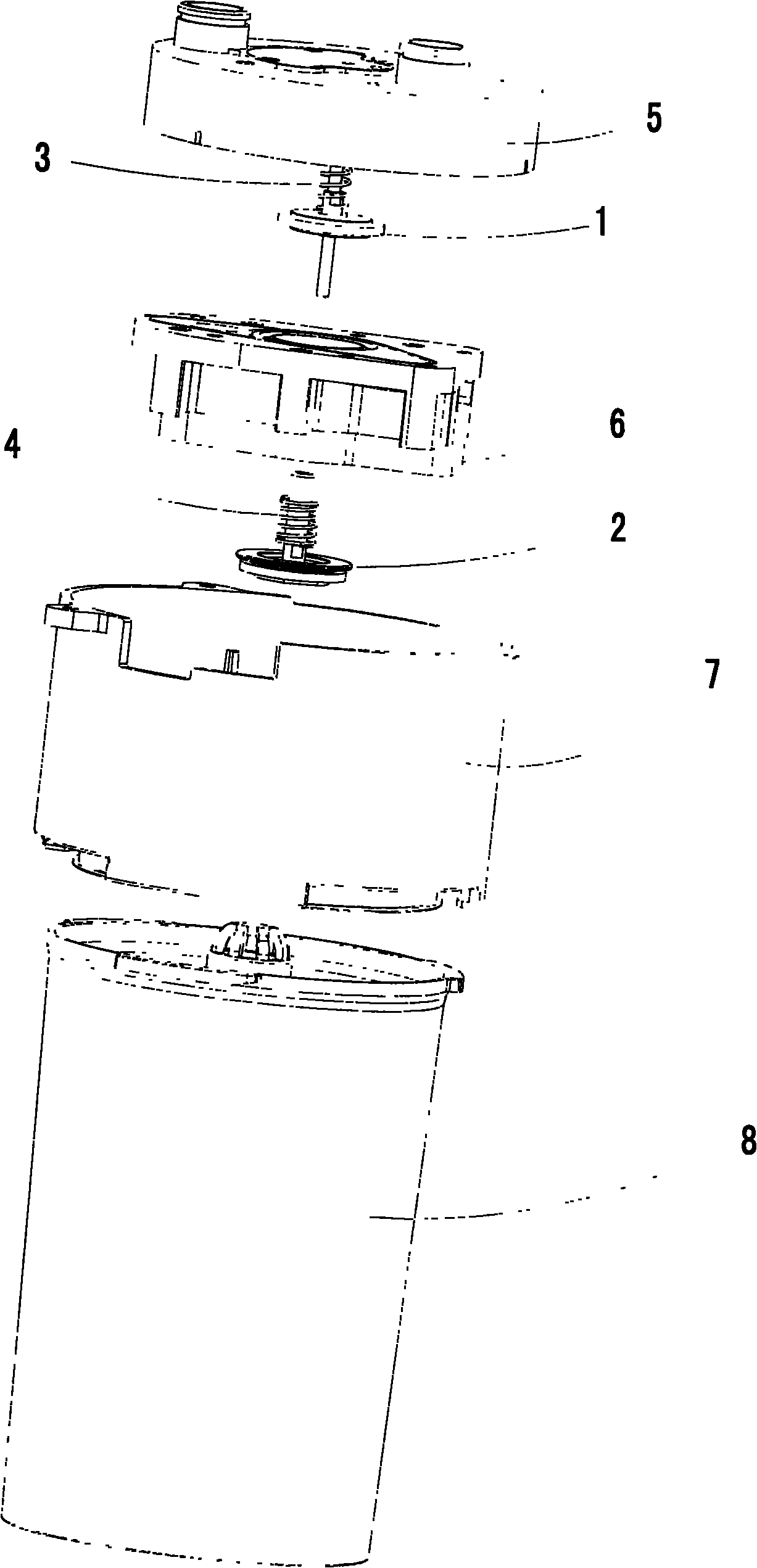

[0020] a kind of like Figure 1~4 Anesthesia machine shown with carbon dioxide absorber, including CO 2 The absorption tank 8, and the control components arranged between the breathing circuit 201 and the bypass device 202.

[0021] The control part is a pilot isolation valve 1 and a transmission isolation valve 2 arranged in series on the installation base 6, and the control part includes a 2 The top block at the top of the absorption tank 8 is linked with the guide linkage rod, the installation base 6 is firmly connected with the bottom of the gas exchange main body 7, the top of the gas exchange main body 7 is tightly connected with the docking seat 5 of the breathing circuit, the guide isolation valve 1 and the transmission isolation valve 2. In the cavity of the gas exchange main body 7, the upward or downward linkage displacem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com