High-voltage power capacitor device and manufacturing method thereof

A technology of high-voltage electric power and manufacturing method, which is applied in the field of power capacitors and high-voltage power capacitor devices, can solve problems such as unusable, large footprint, and metal frames that cannot be directly grounded, and achieve the effects of easy installation and production, and reduced installation size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

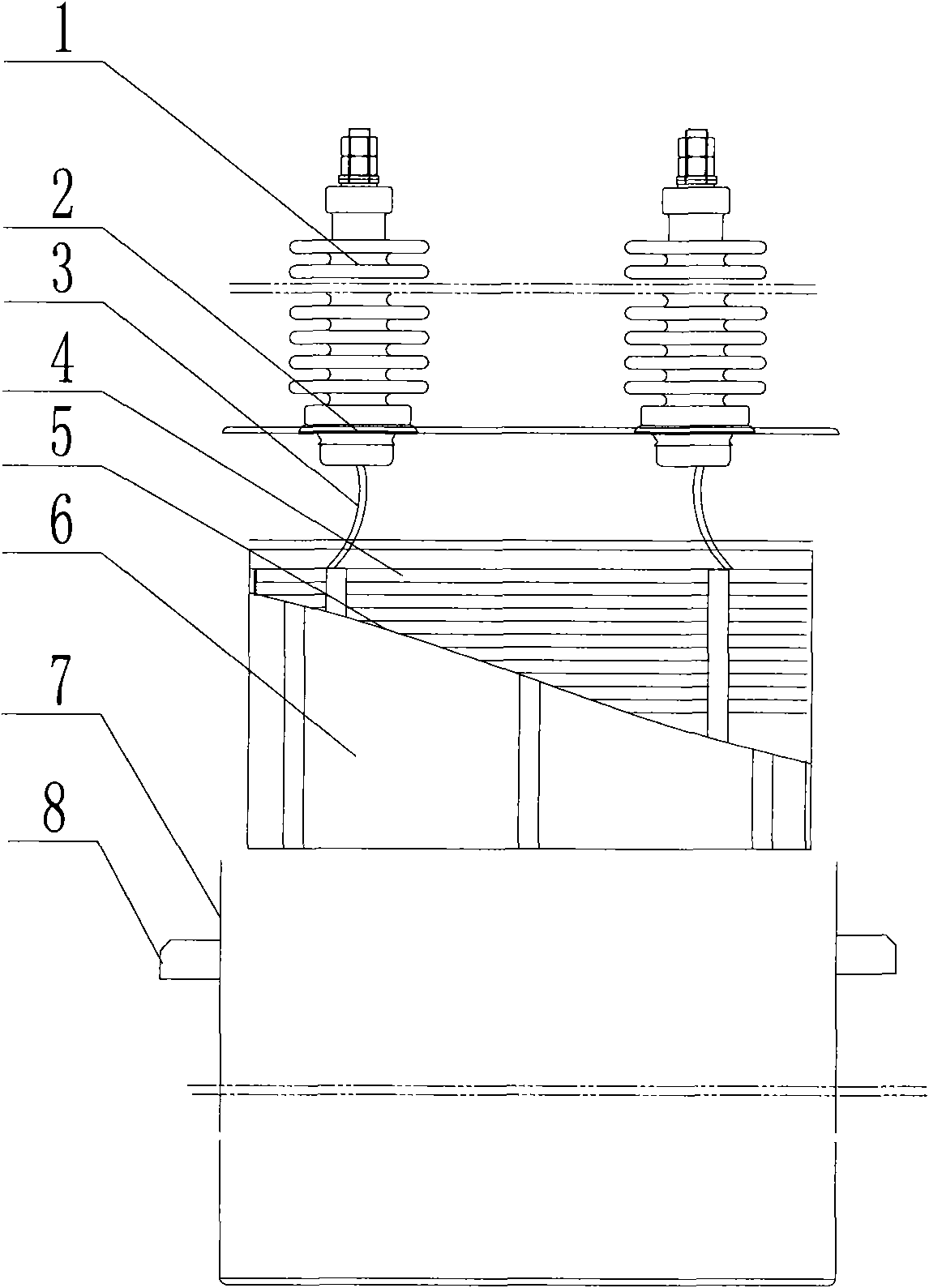

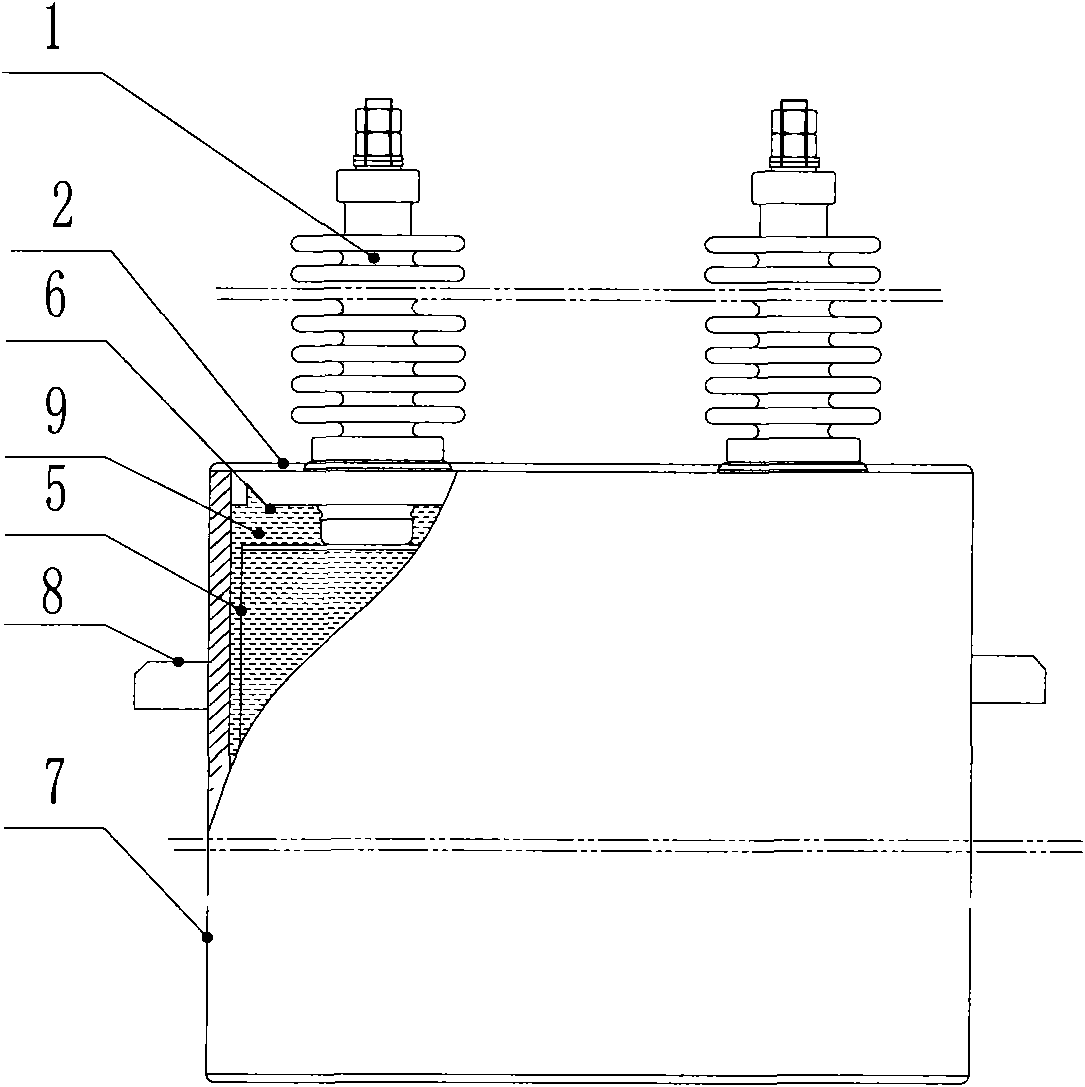

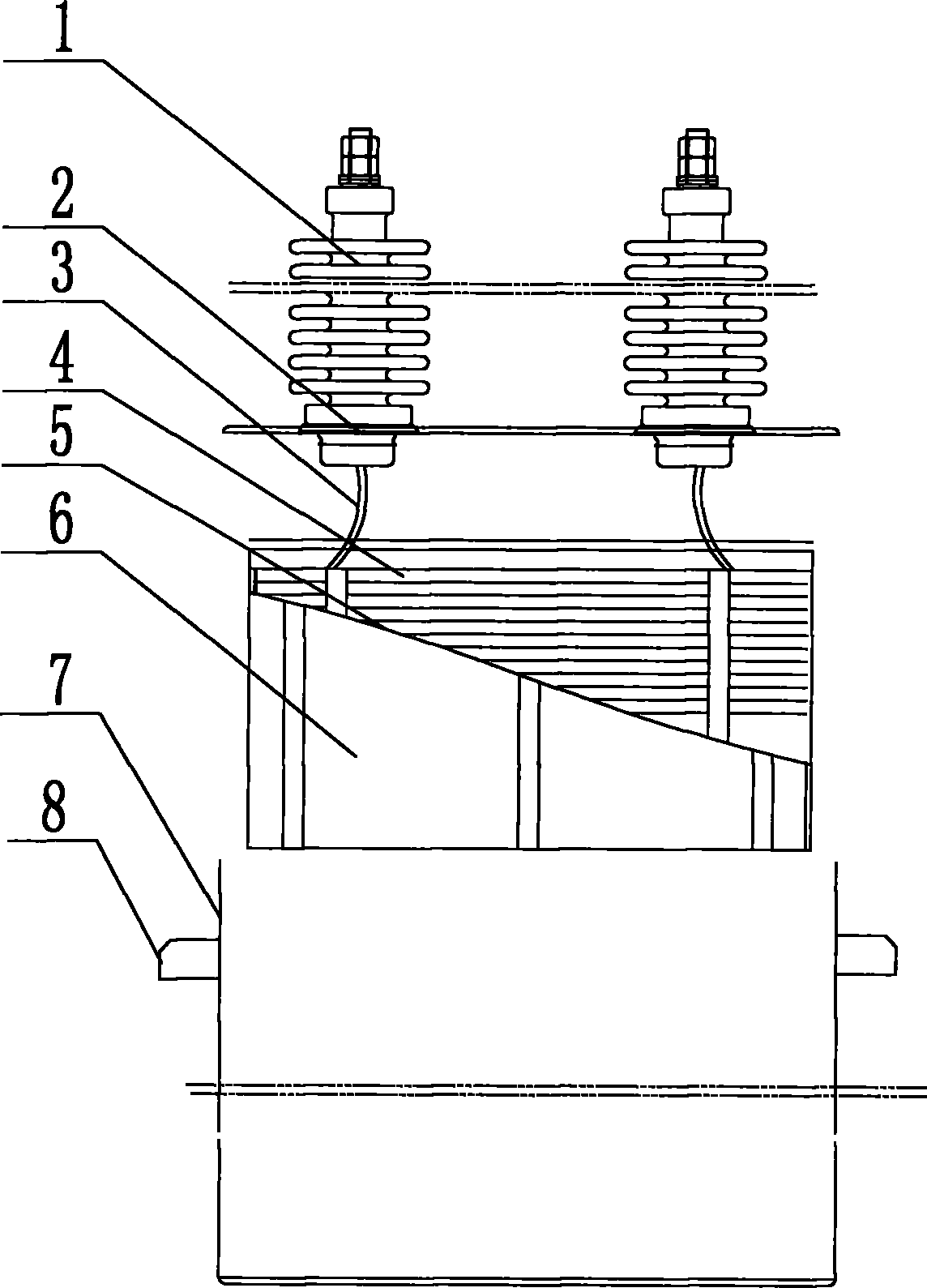

[0017] see figure 1 , figure 2 , An embodiment of a high-voltage power capacitor device of the present invention mainly includes an outlet bushing 1, a case cover 2, a capacitor element 4, a capacitor core 5, a case body 7, and insulating oil 9. Described capacitor core 5 is made up of the capacitor element 4 that is formed by winding and pressing aluminum foil and polypropylene film on the winding machine and then connected in series and parallel with connecting pieces. Part 6 is composed of power cable paper and polypropylene film) and is packaged in the box body 7. The outlet sleeve 1 is fixed on the box cover 2. The wires 3 are connected (can be directly welded), the case cover 2 is welded on the case body 7, and the case body 7 is filled with the insulating oil. The insulation level of the terminal to the box body 7 is 35kV, and can be used in a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com