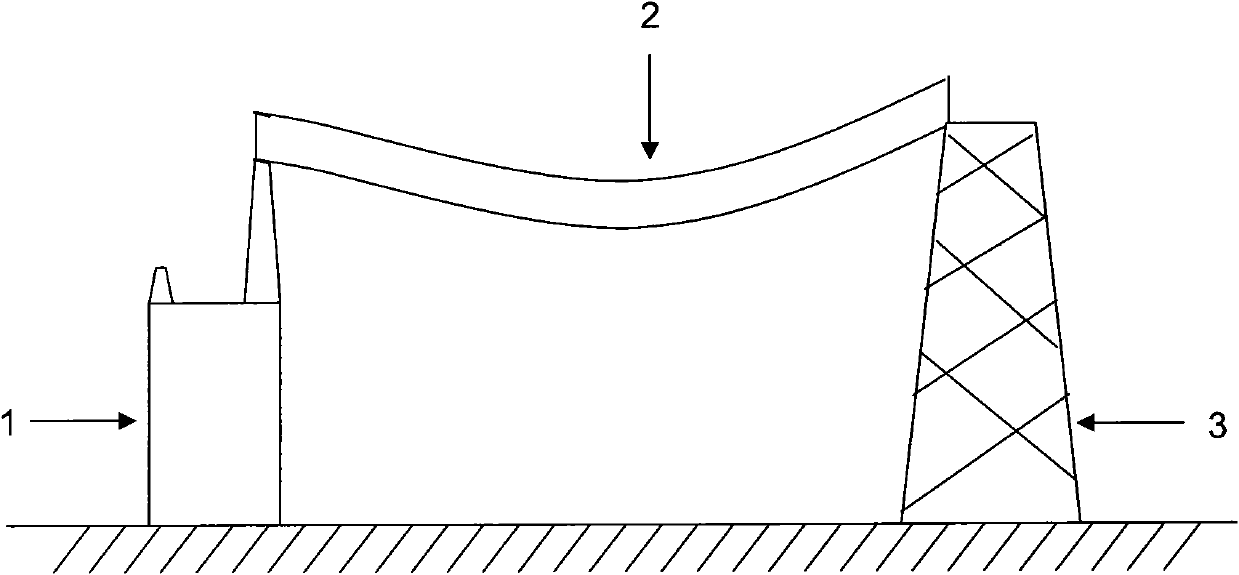

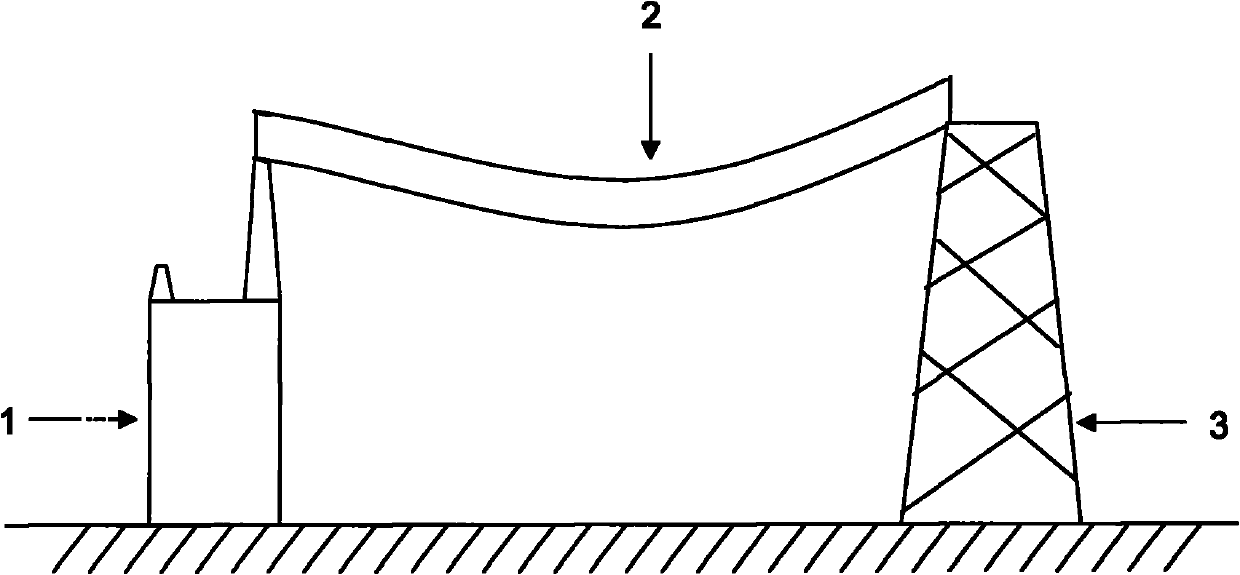

Production process of non-corona wires for high-voltage test

A corona-free wire and manufacturing process technology, applied in cable/conductor manufacturing, circuit/collector parts, electrical components, etc., can solve the problems of difficulty in obtaining finished products, fixed position, high price, etc., and achieve low cost and weight. Robust, easy-to-wire effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The manufacturing process of the halo-free wire for the high voltage test of the present embodiment comprises the following steps:

[0027] 1) Raw material preparation: choose the non-corona wire of the anti-static exhaust duct with a length of 8mΦ300 as the main frame, and choose the red copper wire with a length of 8cm and a diameter of Φ3 as the electrical and mechanical connection parts, and the material with uniform tension at the connection and the material with uniform electric field Choose thick transparent tape and conductive tape; the wire is a hollow metal tube;

[0028] 2) Assembling the halo-free wire: first, connect the skeleton with high strength, that is, connect the two skeleton units end to end, and use copper wire to suture every 35mm at the joint. Lightly tap with a small wooden hammer to close the circle, and then use transparent tape to bind the sutures. When binding, extend 45mm to the unsewed parts of the two skeletons. Bundle a total of 3 circle...

Embodiment 2

[0033] The manufacturing process of the halo-free wire for the high voltage test of the present embodiment comprises the following steps:

[0034] 1) Raw material preparation: choose anti-static exhaust duct non-corona wire with a length of 8mΦ500 as the main frame, choose copper wire with a length of 8cm and a diameter of Φ3 as the electrical and mechanical connection parts, materials with uniform tension at the joints and materials with uniform electric field Choose thick transparent tape and conductive tape; among them, choose hollow metal cylinder for wire;

[0035] 2) Assembling the halo-free wire: first, connect the skeleton with high strength, that is, connect the two skeleton units end to end, and use copper wire to suture every 50mm at the joint. Lightly tap with a small wooden hammer to close the circle, and then use transparent tape to bind the sutures. When binding, extend 60mm to the unsewn parts of the two skeletons. Bundle a total of 5 circles for even tension t...

Embodiment 3

[0040] The manufacturing process of the halo-free wire for the high voltage test of the present embodiment comprises the following steps:

[0041] 1) Raw material preparation: choose anti-static exhaust duct non-corona wire with a length of 8mΦ500 as the main frame, choose copper wire with a length of 8cm and a diameter of Φ3 as the electrical and mechanical connection parts, materials with uniform tension at the joints and materials with uniform electric field Choose thick transparent tape and conductive tape; among them, choose hollow metal cylinder for wire;

[0042] Step 2): Assembling the halo-free wire: first, connect the skeleton with high strength, that is, connect the two skeleton units end-to-end, and suture every 40mm with copper wire at the joint, and the protrusions produced after suturing must use small glue Tap with a hammer or a small wooden hammer to close the circle, and then use transparent tape to bind the sutures. When binding, extend 50mm to the unsewn pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com