Novel high-efficiency heat exchange pipe for condenser of electric refrigeration unit

A condenser and electric refrigeration technology, applied in the field of heat exchange tubes for strengthening condensation heat transfer and convective heat transfer, and heat exchange tubes for condensers of electric refrigeration units, to achieve weakened liquid hanging capacity, increase condensation heat transfer coefficient, and liquid retention angle Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

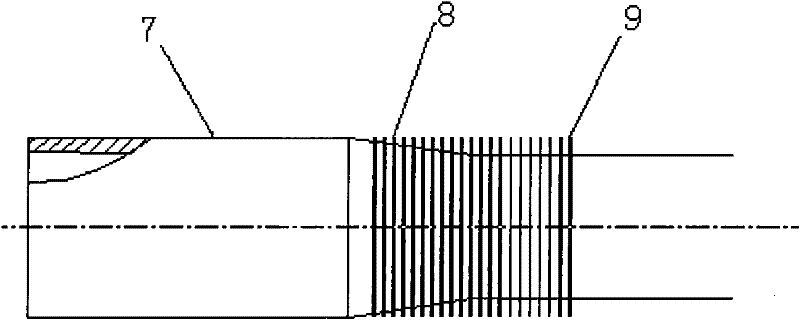

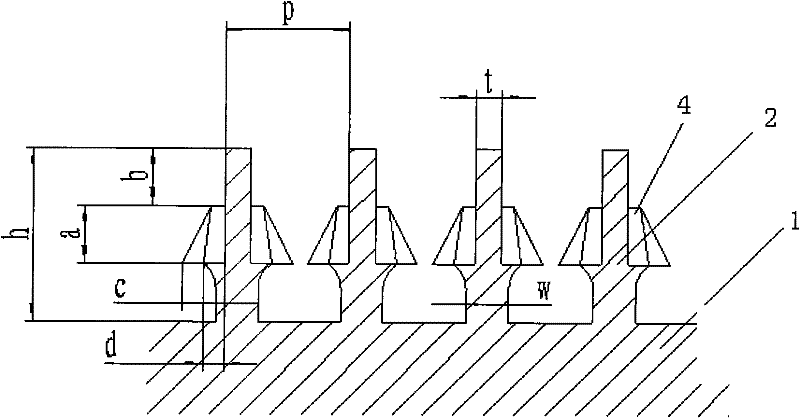

[0025] Embodiment 1: A kind of novel high-efficiency heat exchange tube for condenser of electric refrigeration unit (see figure 1 , figure 2 , image 3 , Figure 4 , Figure 9 ), which includes a smooth tube 7 and a fin section 9, the smooth tube 7 is connected to the fin section 9 through a transition section 8 provided with spiral fins outside the tube body, and the tube body 1 of the fin section 9 is provided with a certain spiral shape with the central axis of the tube. Helical fins 2 that extend spirally along the outer surface of the tube, the outer diameter of the fins 2 of the fin segment 9 is less than or equal to the outer diameter of the smooth tube 7, the top 2B of the helical fins 2 is thinner than the root 2A, and the outer diameter of the helical fins 2 The upper ends of the two sides are smooth surfaces 3, and the middle of the two sides of the spiral fin 2 is provided with an oblique fin 4 that is 30 to 70 degrees from the axial direction of the tube. Th...

Embodiment 2

[0028] Embodiment 2: A kind of novel high-efficiency heat exchange tube for condenser of electric refrigeration unit (see Figure 5 , Image 6 , Figure 9 ), which is basically the same as Embodiment 1, the difference is that this embodiment is to strengthen the heat transfer performance outside the tube, and a certain depth of sawtooth-shaped circumferential grooves 10 are processed on the top of the spiral fin 2, and the sawtooth-shaped circumferential grooves 10 forms a 30-90 degree oblique angle with the oblique fin 4, and in this embodiment, the circumferential alveolar 10 forms an oblique angle with the oblique fin 4 at a 45 degree angle. While increasing the area, the number of sharp points on the top is increased, and the disturbance of the condensate is increased. The depth e of the circumferential alveolar groove 10 is 0.05-0.4 mm, and the pitch pt is 0.4-1.0 mm.

Embodiment 3

[0029] Embodiment 3: A kind of novel high-efficiency heat exchange tube for condenser of electric refrigeration unit (see Figure 7 , Figure 8 , Figure 9 ), which is basically the same as Embodiment 1, the difference is that this embodiment is to strengthen the heat transfer performance outside the tube, and a certain depth of sawtooth-shaped circumferential grooves 10 are processed on the top of the spiral fin 2, and the sawtooth-shaped circumferential grooves 10 forms a 30-90 degree oblique angle with the oblique wing 4, and in this embodiment, the circumferential alveolar 10 forms a 90 degree angle with the oblique wing 4. While increasing the area, the number of sharp points on the top is increased, and the disturbance of the condensate is increased. The depth e of the circumferential alveolar groove 10 is 0.05-0.4 mm, and the pitch pt is 0.4-1.0 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com