Intelligent energy-saving mixed water heat supply method

An intelligent, water-mixing technology, applied in household heating, heating methods, heating systems, etc., can solve problems such as increased secondary network resistance, high return water pressure of primary network, and improved pressure resistance of primary network pipes, achieving Guarantee the effect of individual needs and optimization of mixing ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

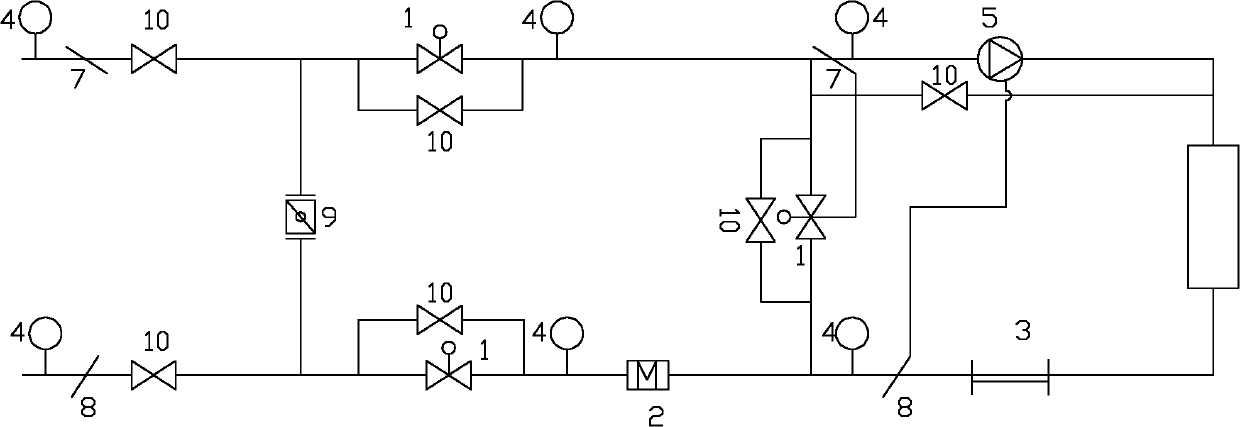

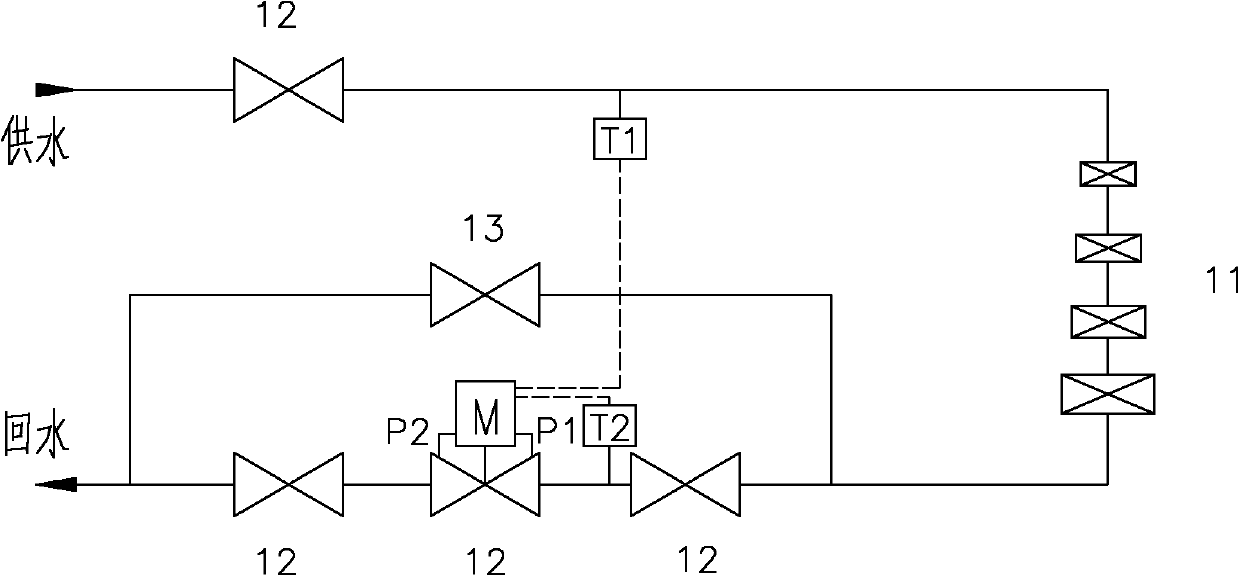

Method used

Image

Examples

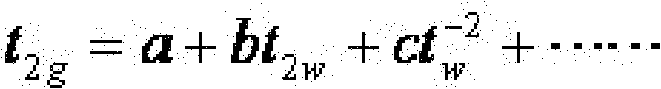

Embodiment 1

[0051]First, determine the corresponding secondary supply and return water temperature (average temperature of secondary supply and return water) through the outdoor temperature sensor, and determine the corresponding indoor temperature according to the type of section and time period where the user is located, and use the corresponding area and unit area Heat load coefficient, quickly calculate the heat load corresponding to each branch pipe of the secondary network, select the appropriate pipe specific friction resistance under the given secondary pipe network conditions, determine the corresponding circulation flow required by the branch pipes, and determine after summarizing The total circulation flow of the secondary pipe network fundamentally ensures that the operation of the secondary network itself is under the premise of large temperature difference and small flow. Under the condition of optimized water mixing ratio, according to the operation control mode adopted by t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com