Balanced valve bank of derricking cylinder system

A system balance, luffing cylinder technology, applied in the direction of fluid pressure actuation system components, servo motor components, fluid pressure actuation devices, etc. Oil cylinder sinking and other problems, to achieve the effect of reducing system pipeline layout, good balance effect, and reducing pressure drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

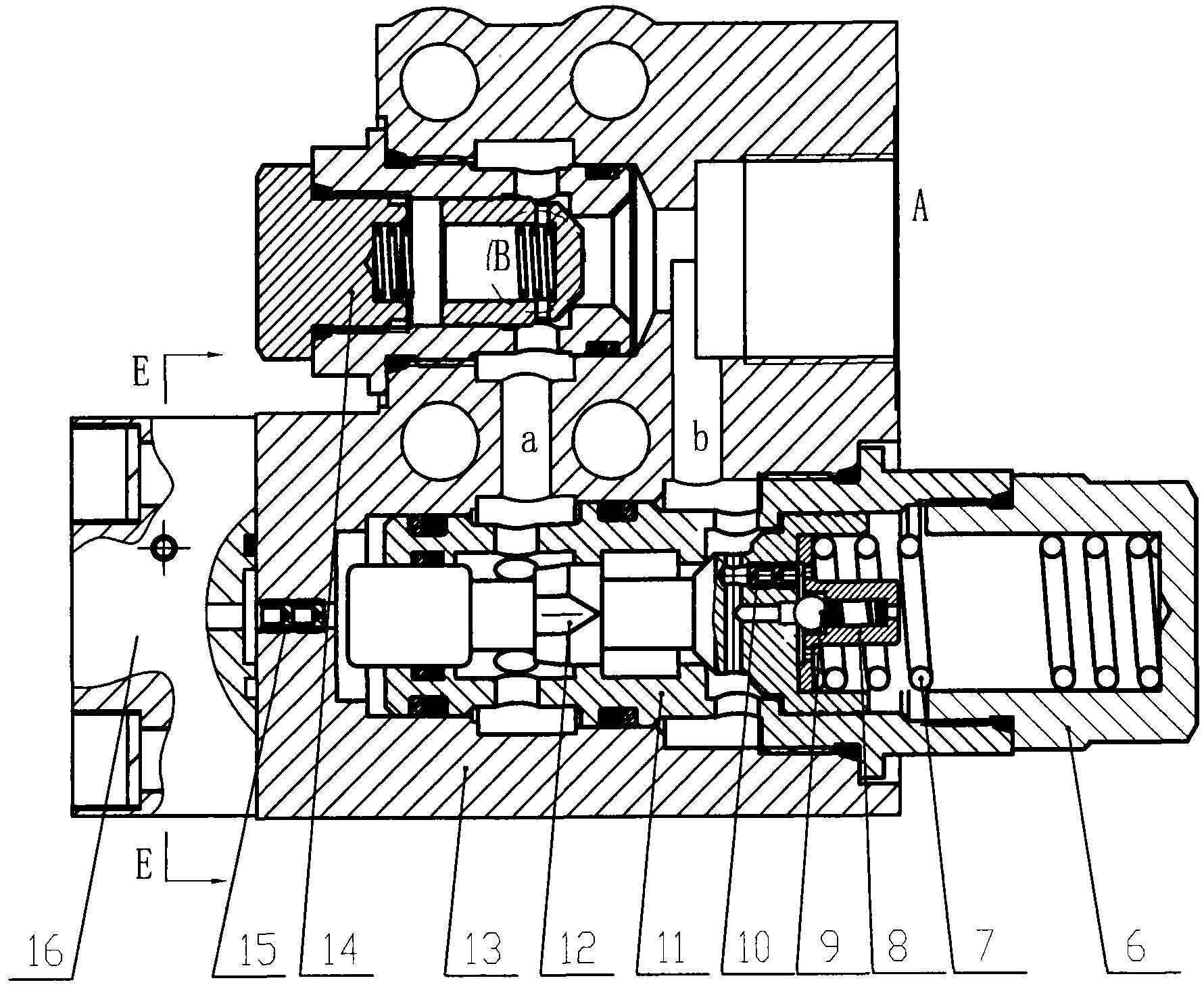

[0011] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

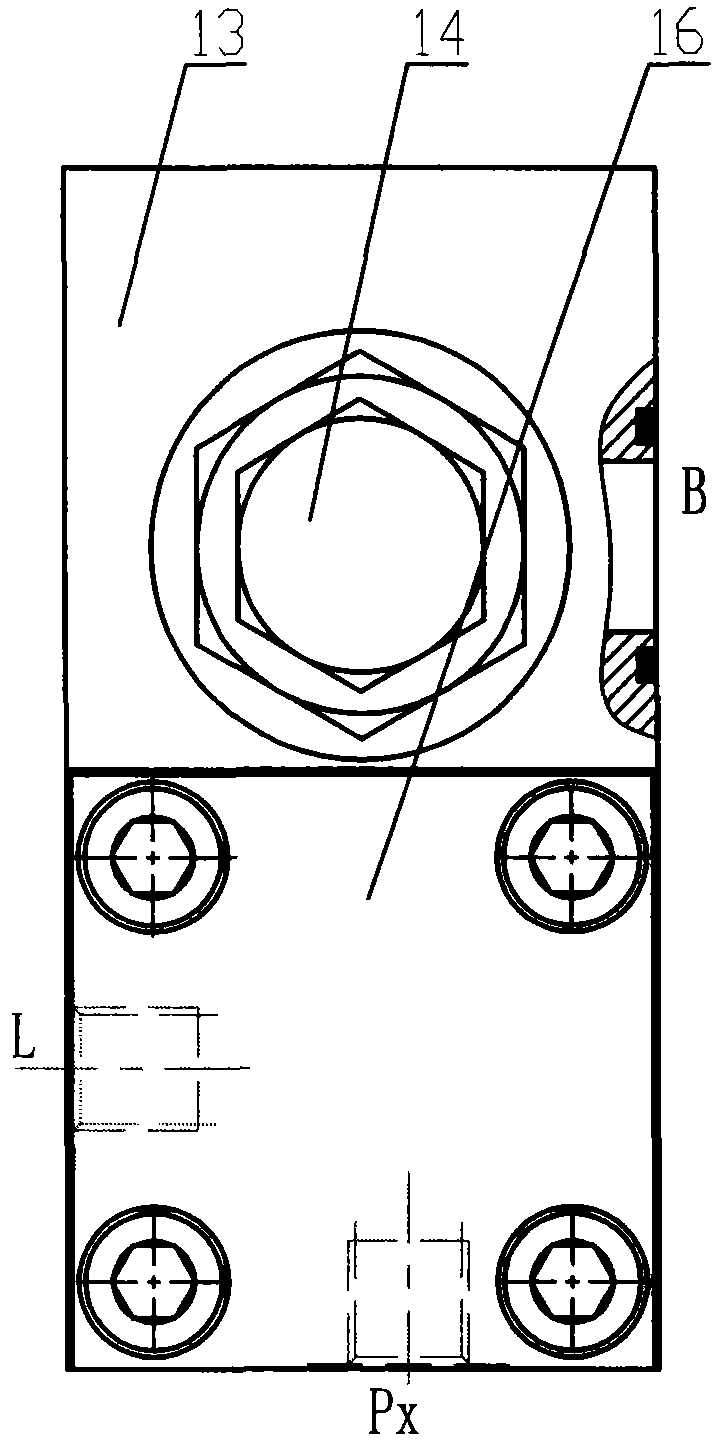

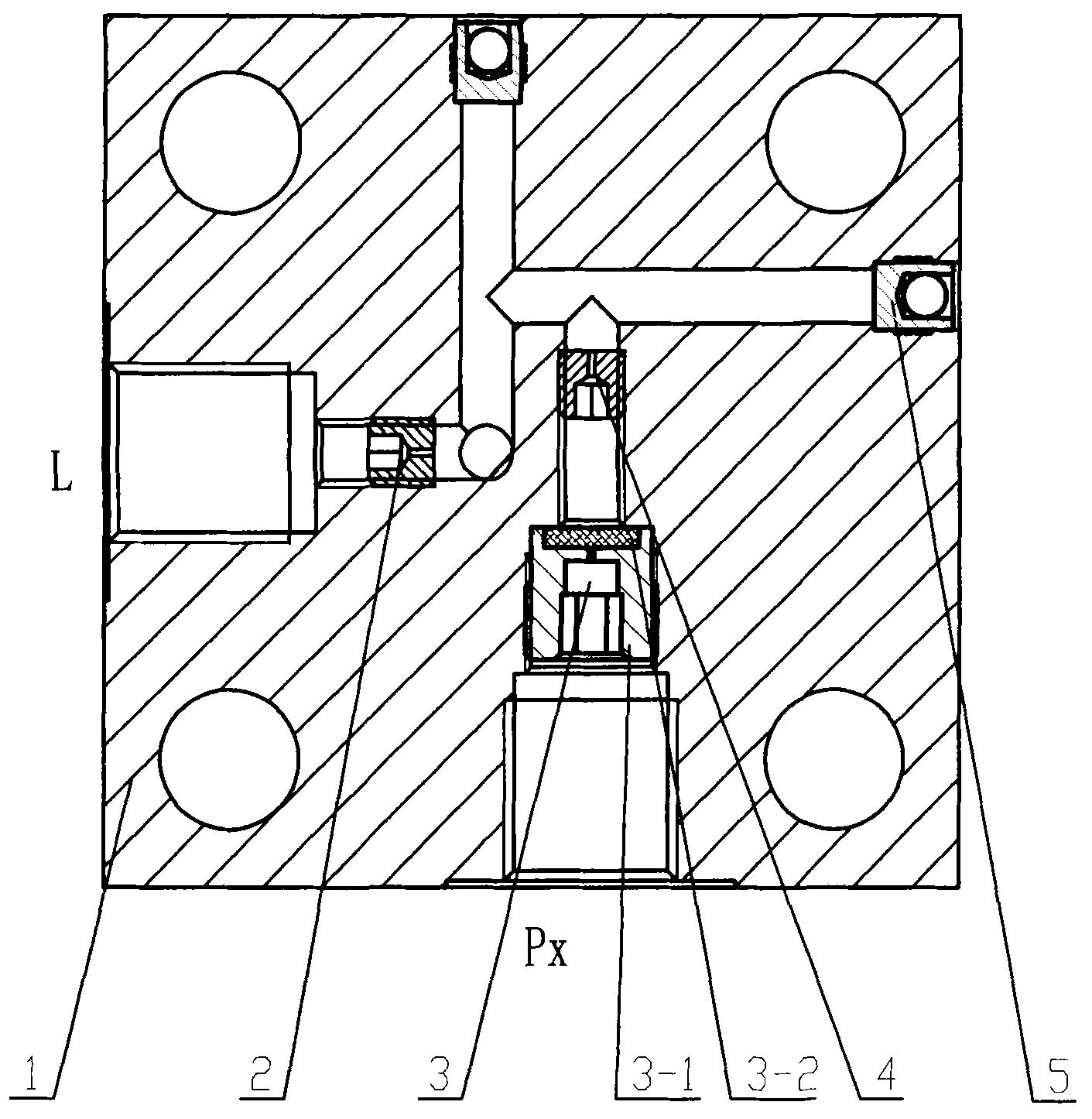

[0012] There are installation holes on the four corners of the end cover valve body 1 of the control end cover 16, there are oil pipe ball plugs 5 on the adjacent two side walls, and there are control oil ports Px on the other two adjacent side walls to connect with the rod cavity of the luffing cylinder , the unloading oil port L is connected to the fuel tank, and the two oil pipe ports of the two oil ports are connected with damper I2 and damper II4 with threads, and the filter screen damper 3 is also threaded in the middle of the control oil port Px, and the filter screen damper 3 is connected by the joint 3-1 The upper end surface groove is tightly embedded with the filter screen 3-2, and there is a hexagonal blind hole in the middle of the joint for easy installation and use, such as image 3 shown.

[0013] The control end cover 16 is fixed on one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com