Outer hanging-wall plate connecting piece

A technology for hanging wallboards and connectors, which is applied to walls, building components, buildings, etc., can solve the problems of increasing the cost of wallboards, increasing manufacturing and processing costs, and cracking of welded joints, so as to enhance the overall seismic performance, enhance ductility and Integrity, the effect of good seismic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

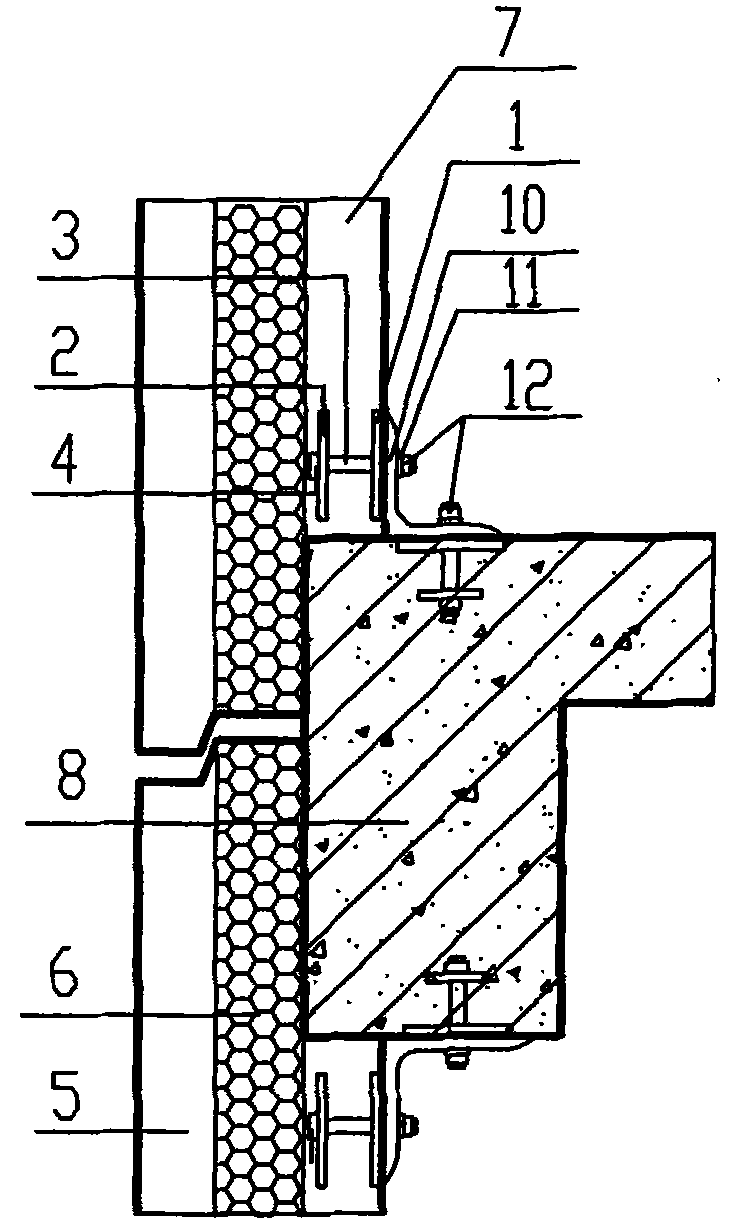

[0011] refer to figure 1 , the present invention comprises a surface layer steel plate 1, an inner layer steel plate 2, a bolt rod 3, and a nut 4, the surface layer steel plate and the inner layer steel plate are connected by two bolt rods 3, one end of the bolt rod 3 protrudes from the inner layer steel plate 2 and The nut 4 is fixed on the inner steel plate 2, and the other end protrudes from the surface steel plate 1. The distance between the surface steel plate 1 and the inner steel plate 2 is consistent with the thickness of the external wall panel structure layer 7.

[0012] refer to figure 2 , in the processing and manufacturing stage, the new connecting piece needs to be embedded in the external wall panel structure layer 7 and the frame beam 8 in advance. Its position is as follows: the surface steel plate 1 is located on the surface of the external wall panel structure layer 7 or the upper and lower surfaces of the frame beam 8 , and the inner layer steel plate 2 i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile load | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com