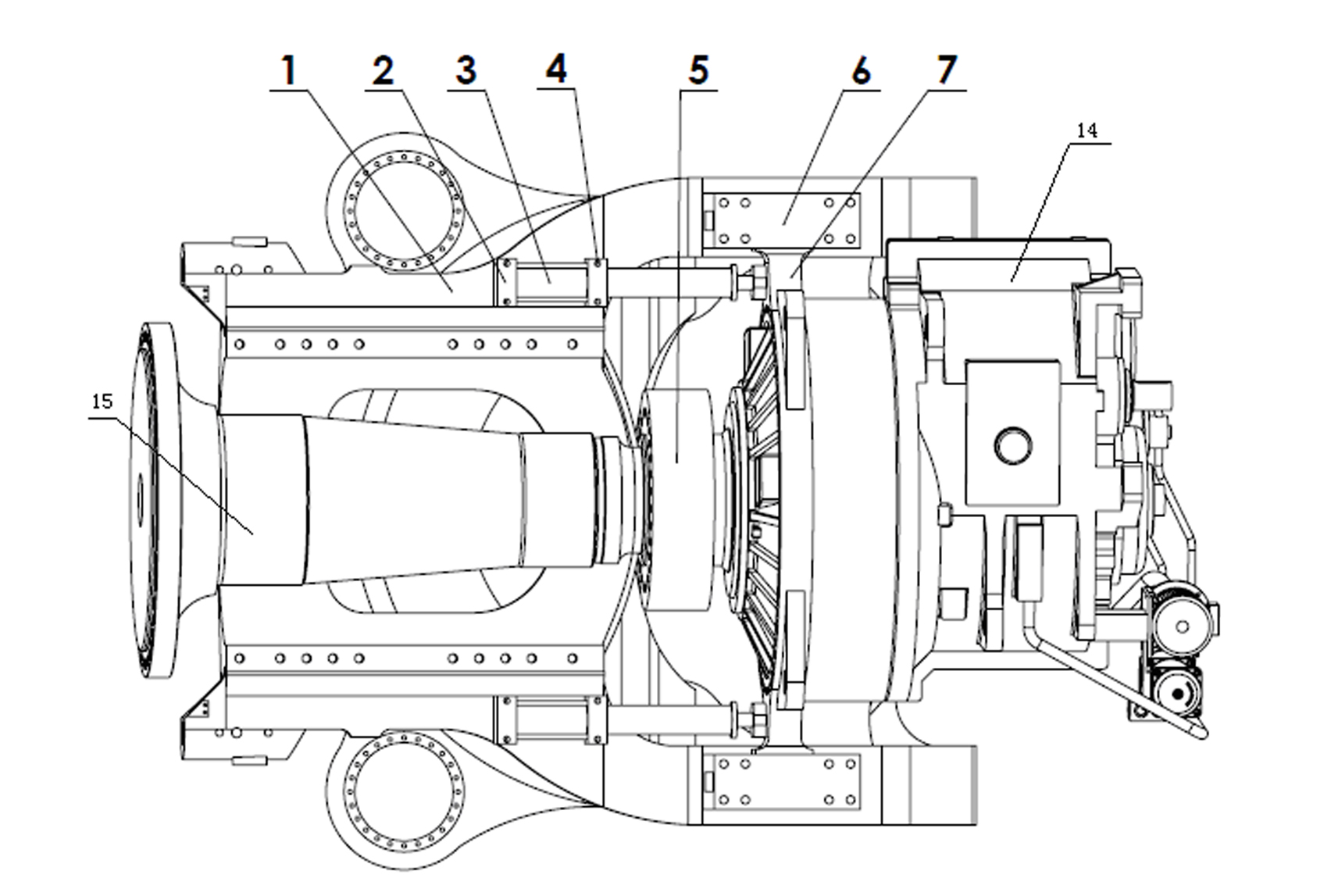

Method and device for disassembling gear box of wind driven generator

A technology for wind turbines and dismantling devices, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as difficulty in repairing and inconvenient natural environment and transportation, shortening maintenance time, reducing maintenance costs, and achieving firmness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

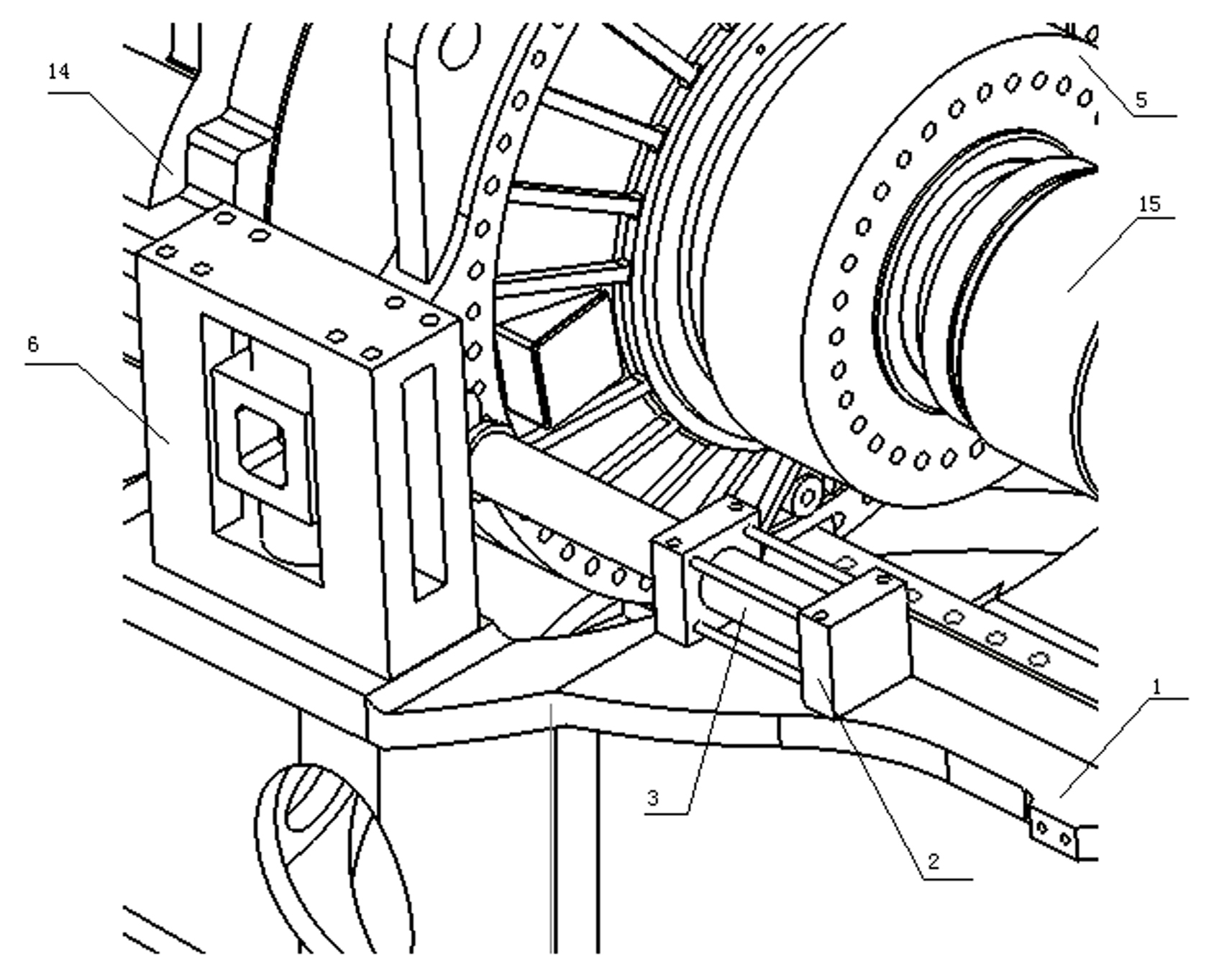

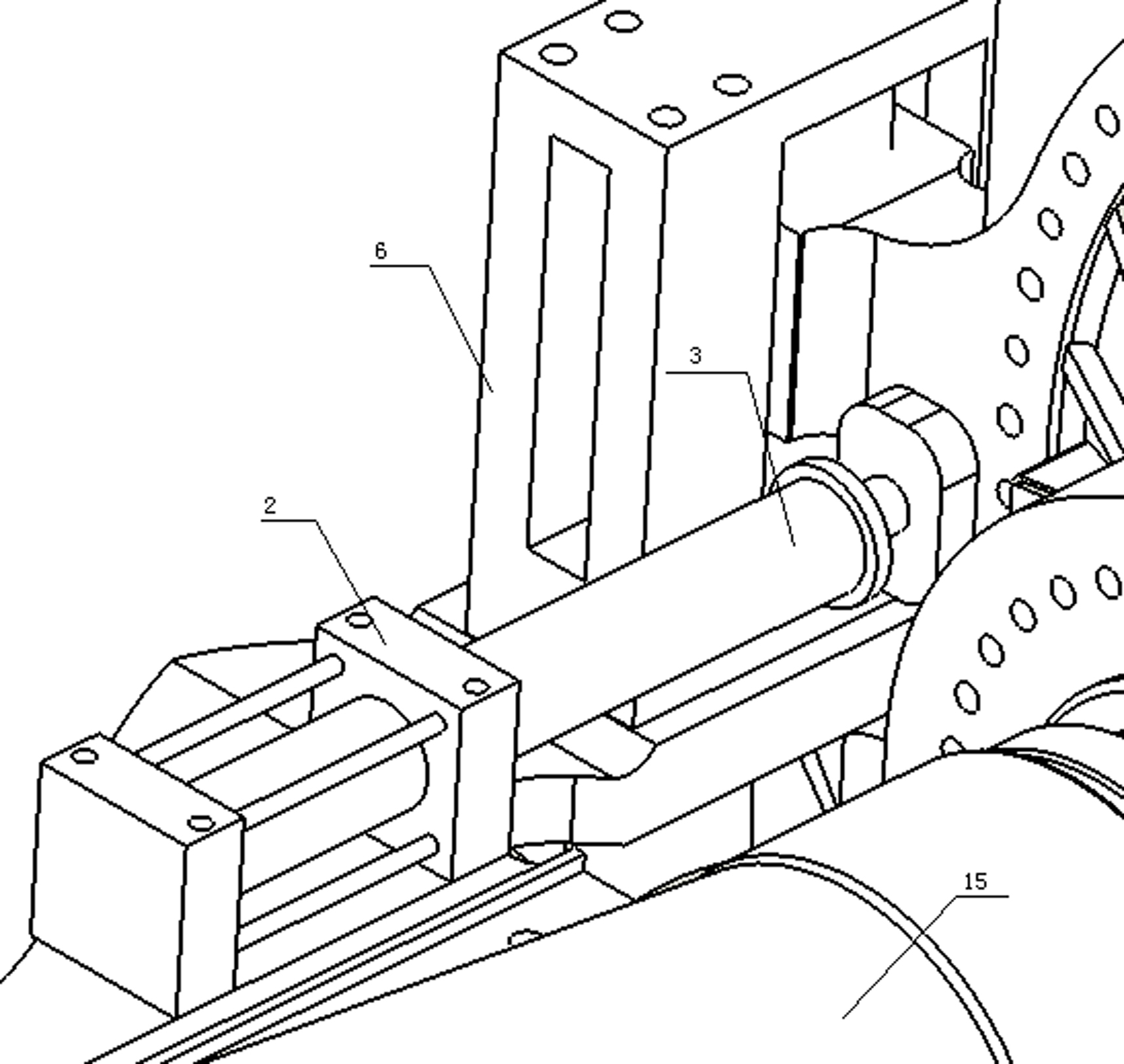

[0023] In the wind power generator gearbox dismounting method of the present invention, the gearbox is provided with two gearbox torque arms, and the two gearbox torque arms are all fixed on the front nacelle chassis through elastic support seats; the wind wheel output shaft It is connected with the input shaft of the gearbox through an expansion sleeve, and the special feature is that the disassembly method includes the following steps: a) firstly hang the gearbox on the crane arm through a rope; b) loosen the expansion sleeve and the elastic support The nut on the seat disconnects the gearbox from the chassis of the front nacelle; c) Set a hydraulic jack on both sides of the output shaft of the wind rotor, and the movement direction of the piston rod of the hydraulic jack is the same as that of the output shaft of the wind rotor; The bottom end of the jack is fixed to the underframe of the front nacelle, and the top of the hydraulic jack is in contact with the gear box; d) Si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com