Double-chamber high-temperature forging and forming device of TiAl intermetallic compound forge piece and method thereof

An intermetallic compound and forging technology, which is used in forging/pressing/hammer devices, metal processing equipment, manufacturing tools, etc., can solve the problems of difficult to complete forging, excessive heat dissipation of the billet, and large deformation resistance, and achieve the amount of billet deformation. Increase or decrease the number of forging passes and relieve the effect of high deformation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

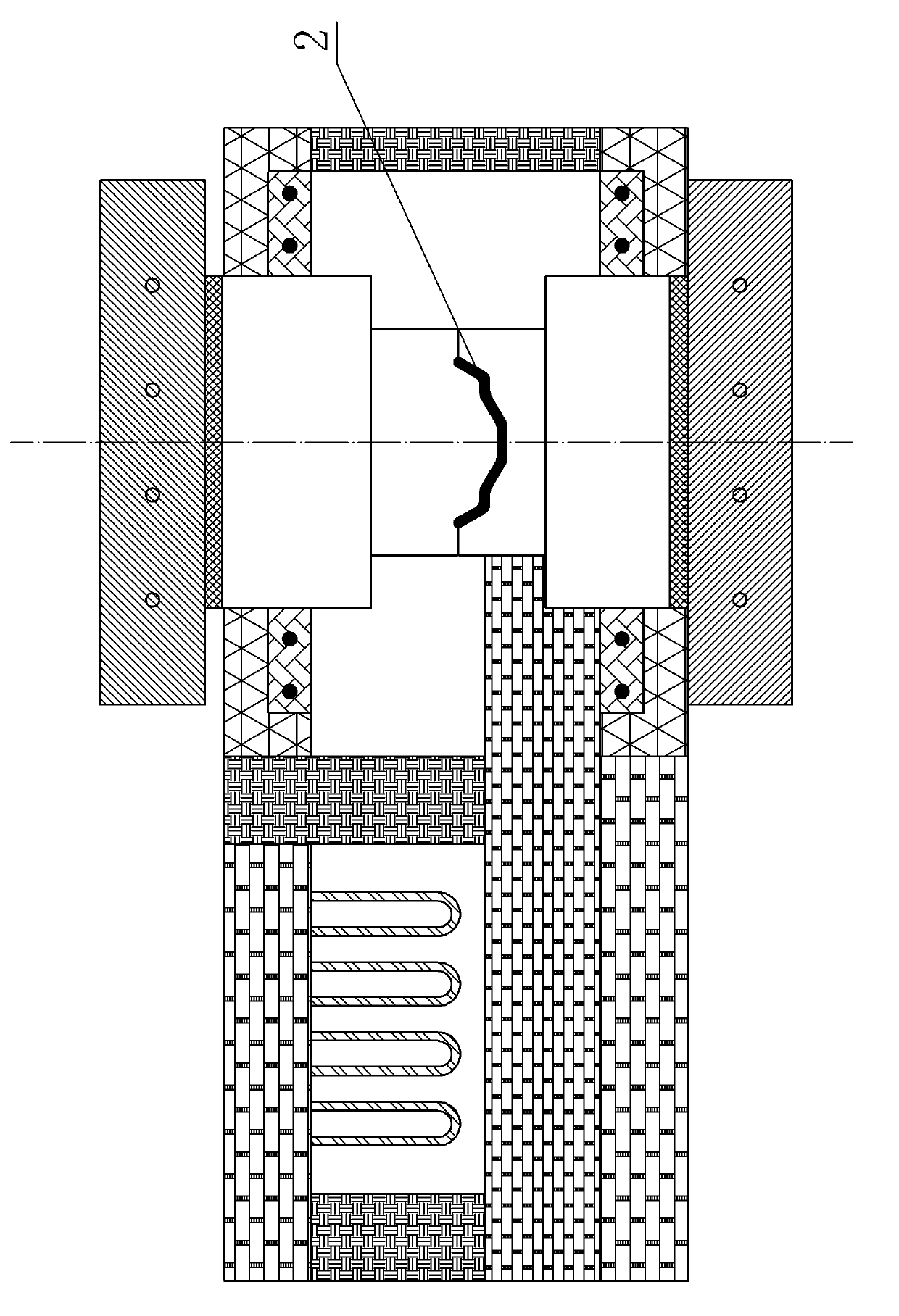

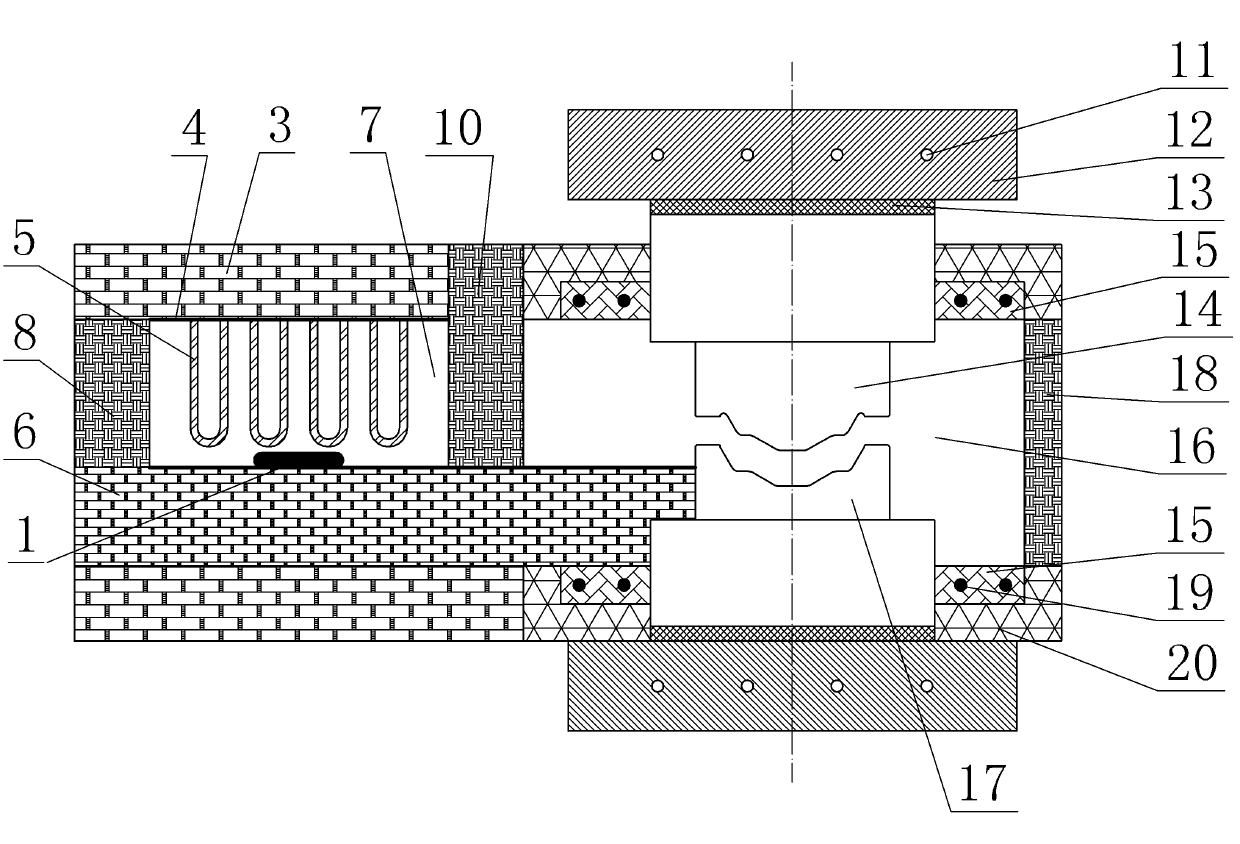

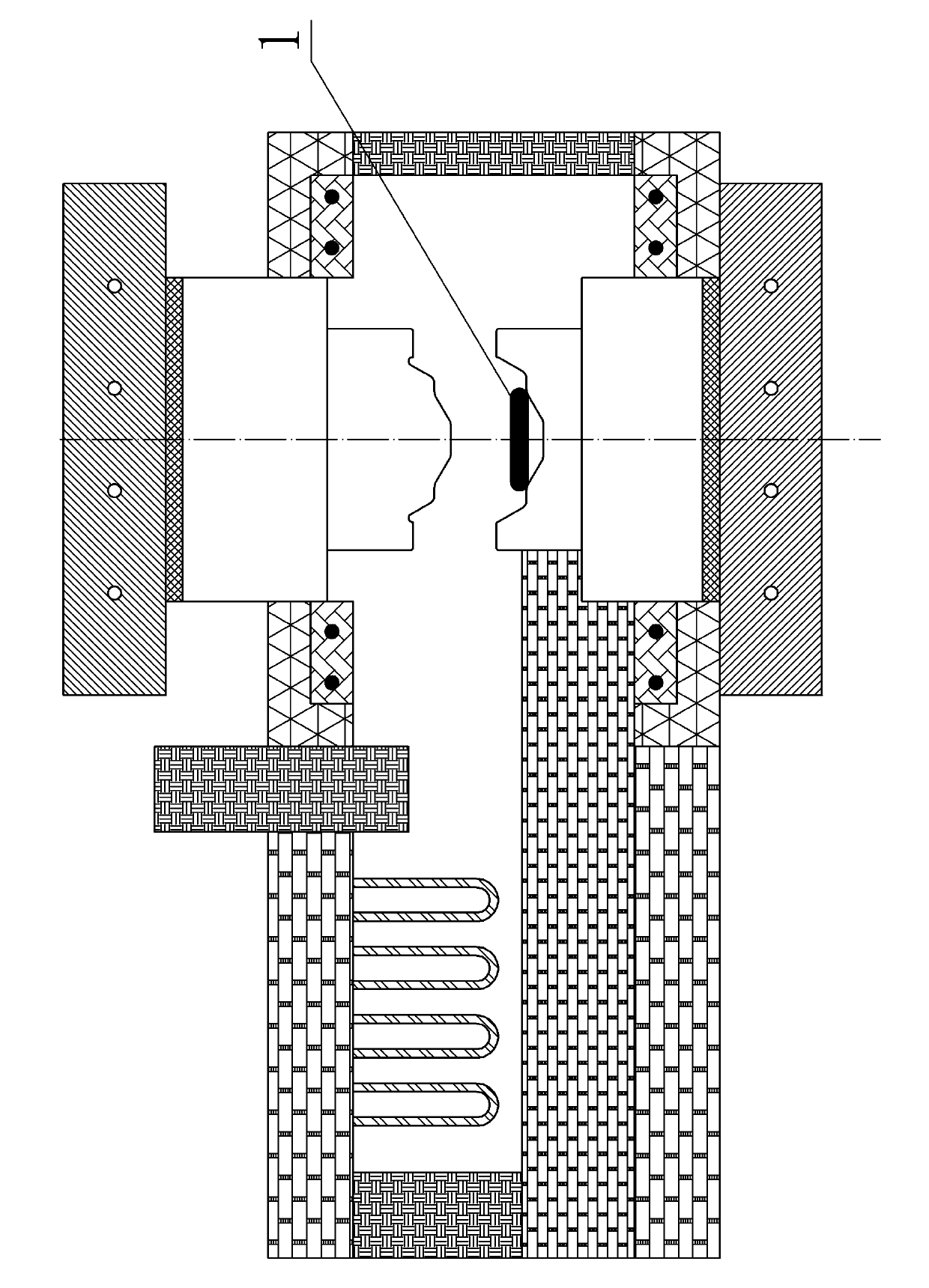

[0018] Specific implementation mode one: combine figure 1 , figure 2 , image 3 To illustrate this embodiment, the double-chamber high-temperature forging forming device for TiAl intermetallic compound forgings described in this embodiment includes a high-temperature heating element 5 for a billet, a high-temperature heating element 19 for a mold, a punch 14, and a die 17, which are characterized in that: The forming device also includes a blank heating chamber 7, a mold heating chamber 16, and a movable partition 10. The blank heating chamber 7 and the mold heating chamber 16 are adjacently arranged and a movable partition 10 is arranged between the two, which can be moved by pulling up and down. The partition 10 can realize the mutual penetration of the furnace of the billet heating chamber 7 and the furnace of the mold heating chamber 16 (when the movable partition 10 is pulled upward, the furnace of the blank heating chamber 7 and the furnace of the mold heating chamber ...

specific Embodiment approach 2

[0021] Specific implementation mode two: combination figure 1 , figure 2 , image 3 Describe this embodiment, the billet heating chamber 7 in this embodiment includes a billet heating chamber furnace body 3 and a billet heating chamber furnace door 8, and the billet heating chamber furnace door 8 is installed on the billet heating chamber furnace body away from the mold heating chamber 16 3 on the side wall. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0022] Specific implementation mode three: combination figure 1 , figure 2 , image 3 Describe this embodiment, the mold heating chamber 16 in this embodiment includes a mold heating chamber furnace body 20 and a mold heating chamber furnace door 18, and the mold heating chamber furnace door 18 is installed on the mold heating chamber furnace body far away from the billet heating chamber 7 20 on the side wall. Other components and connections are the same as those in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com