Nanometer titanium dioxide-coated iron oxide yellow composite material and preparation method thereof

A technology of nano-titanium dioxide and composite materials, which is applied in the field of nano-titanium dioxide-coated iron yellow composite materials and its preparation, can solve the problems that have not been seen, and achieve the effects of uniform coating, good process control and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

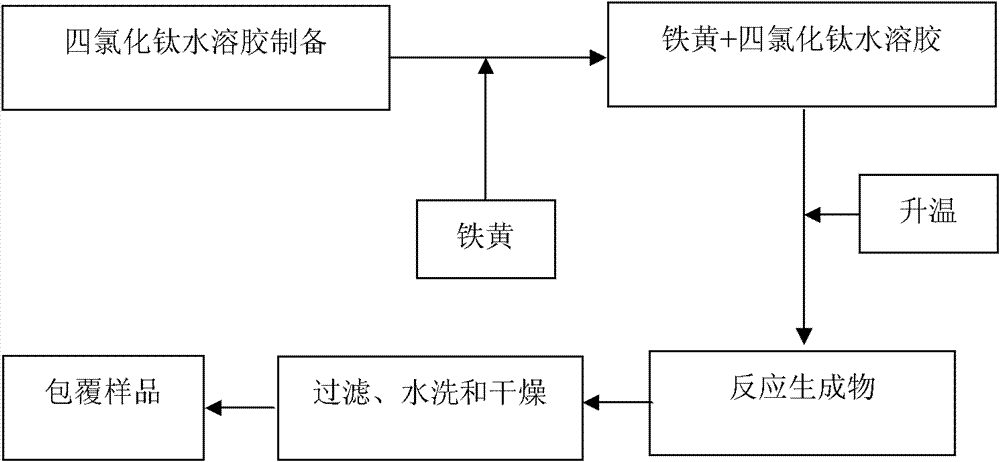

Method used

Image

Examples

Embodiment 1

[0040] (1) Fix a three-neck bottle with a capacity of 500mL in an ice-water bath, take distilled water (H 2 (2) 200mL is packed in the there-necked bottle; A condenser is installed on the middle port of the there-necked bottle, utilizes tap water to condense; A thermometer is installed on a mouth of the there-necked bottle, to monitor and control the temperature of the reaction system; Take TiCl 4 Put 100mL into a dry constant-pressure separating funnel, and install the constant-pressure separating funnel on the other side port of the three-necked flask; under the condition of magnetic stirring and ice-water bath cooling, turn on the switch of the constant-pressure separating funnel, The titanium chloride solution was slowly dropped into distilled water, and the temperature of the entire dropping and mixing process was controlled at about 0°C by controlling the dropping speed and the temperature of the ice-water bath; with the addition of titanium tetrachloride, the color of th...

Embodiment 2

[0045] (1) adopt the device and equipment described in step (1) in embodiment 1, get distilled water (H 2 (2) 200mL is packed into there-necked bottle; Get TiCl 4 Put 100mL into a dry constant-pressure separating funnel; under the conditions of magnetic stirring and ice-water bath cooling, turn on the switch of the constant-pressure separating funnel, slowly drop the titanium tetrachloride solution into pure water, and control the dropping speed and The temperature of the ice-water bath keeps the temperature of the entire dropping and mixing process at about 0°C; after the addition of titanium tetrachloride is completed, continue to stir for 2 hours. At this time, the mixed system is a light yellow-green sol. Cool it to room temperature and place it ;

[0046] (2) Adopt the device and equipment described in step (2) in Example 1, place the titanium tetrachloride hydrosol at room temperature for 6 hours to obtain the aged sol; get 60 mL of the aged sol and pack it into a 500 m...

Embodiment 3

[0050] (1) adopt the device and equipment described in step (1) in embodiment 1, get distilled water (H 2 (2) 200mL is packed into there-necked bottle; Get TiCl 4 Put 100mL into a dry constant-pressure separating funnel; under the conditions of magnetic stirring and ice-water bath cooling, turn on the switch of the constant-pressure separating funnel, slowly drop the titanium tetrachloride solution into pure water, and control the dropping speed and The temperature of the ice-water bath keeps the temperature of the entire dropping and mixing process at about 0°C; after the addition of titanium tetrachloride is completed, continue to stir for 2 hours. At this time, the mixed system is a light yellow-green sol. Cool it to room temperature and place it ;

[0051] (2) Adopt the device and equipment described in step (2) in Example 1, after placing the titanium tetrachloride hydrosol at room temperature for 24 hours, obtain the aged sol; get 60mL of the aged sol and pack it into a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com