Hybrid vaporizer and application thereof to preparation of sulfonated or sulfated product from liquid sulfur trioxide

A technology of liquid sulfur trioxide and sulfur trioxide, which is applied in the direction of sulfuric acid ester preparation, sulfonic acid preparation, chemical instruments and methods, etc., can solve the problem that the pressure of the gas mixture cannot be adjusted, and achieve high conversion rate, good repeatability, color and luster shallow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: Sulfonation of dodecylbenzene

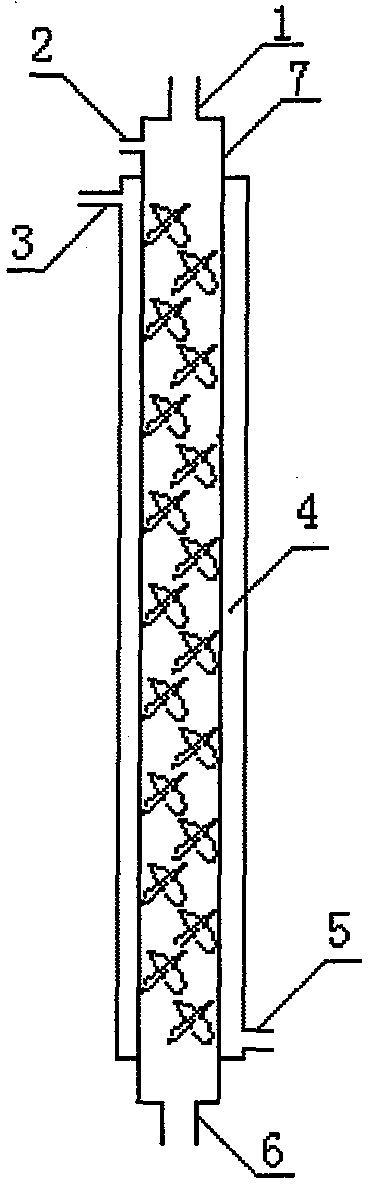

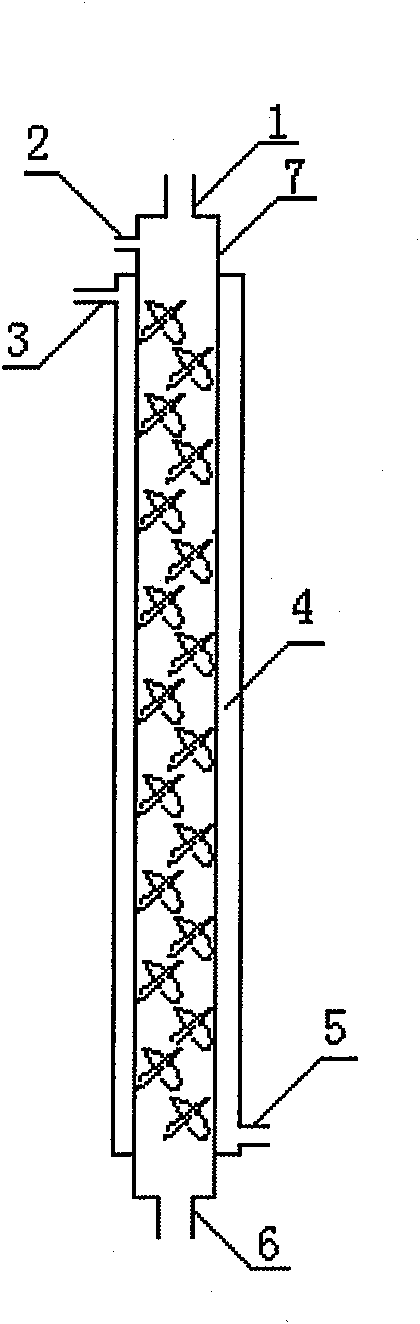

[0022] The mixed vaporizer is composed of a shell 7, a liquid sulfur trioxide inlet 2 and a mixed gas outlet 6. There is a jacket 4 outside the shell 7, and an inert gas inlet 1 and a liquid sulfur trioxide inlet 2 are arranged on the top of the shell 7. There is a circulating water or steam outlet 3 at one end of the jacket 4 at the top of 7, a circulating water or steam inlet 5 at one end of the jacket 4 at the bottom of the shell 7, and a mixed gas outlet 6 at the bottom of the shell 7. The aspect ratio of the mixed vaporizer housing is 15.

[0023] Use nitrogen gas to stabilize the pressure of liquid sulfur trioxide at 0.15MPa, adjust the flow rate of liquid sulfur trioxide at 40°C to 200mL / h, and the flow rate of nitrogen gas to 41.1L / min. 1 and liquid sulfur trioxide inlet 2 enter the mixed vaporizer, the mixed vaporizer is heated by circulating water or steam through the jacket 4, and the temperature is controlled at...

Embodiment 2

[0024] Embodiment 2: the sulfation of fatty alcohol polyoxyethylene ether

[0025] Use nitrogen gas to stabilize the pressure of liquid sulfur trioxide at 0.15MPa, adjust the flow rate of liquid sulfur trioxide at 35°C to 200mL / h, and the flow rate of nitrogen gas to 55.4L / min. 1 and liquid sulfur trioxide inlet 2 enter the mixed vaporizer, the mixed vaporizer is heated by circulating water or steam through the jacket 4, and the temperature is controlled at 65°C. After stabilizing for 30 minutes, the outlet pressure of the mixed gas is adjusted to 0.1MPa through the pressure reducing valve, and then mixed The gas is cooled and the filter is adjusted to 30°C. By controlling the molar ratio of sulfur trioxide to organic material to be 1.01:1, that is, the flow rate of fatty alcohol polyoxyethylene ether (average molar mass is 326) is 1.5kg / h. Sulfur oxide mixed gas and organic materials enter and flow down from the top of the sulfonation reactor to complete the sulfation reactio...

Embodiment 3

[0026] Example 3: Sulfonation of heavy alkylbenzenes

[0027] Use nitrogen gas to stabilize the pressure of liquid sulfur trioxide at 0.13MPa, adjust the flow rate of liquid sulfur trioxide at 42°C to 200mL / h, and the flow rate of nitrogen gas to 32.6L / min. 1 and liquid sulfur trioxide inlet 2 enter the mixed vaporizer, the mixed vaporizer is heated by circulating water or steam through the jacket 4, and the temperature is controlled at 80°C. After stabilizing for 30 minutes, the outlet pressure of the mixed gas is adjusted to 0.3MPa through the pressure reducing valve, and then mixed The gas is cooled and the filter is adjusted to 60°C. By controlling the molar ratio of sulfur trioxide to organic material to be 1.5:1, that is, the flow rate of heavy alkylbenzene (average molar mass 265) is 0.81kg / h, and then the sulfur trioxide is mixed Gas and organic materials enter and flow down from the top of the sulfonation reactor to complete the sulfonation reaction. The heat of reac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com