Anticorrosive structure penetrating through external anticorrosive layer of pipe and preparation method thereof

A technology of anti-corrosion layer and pipeline, which is applied in pipeline anti-corrosion/rust protection, pipeline damage/wear prevention, pipeline protection, etc. It can solve problems such as damage and achieve low production cost, strong stability and convenient production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

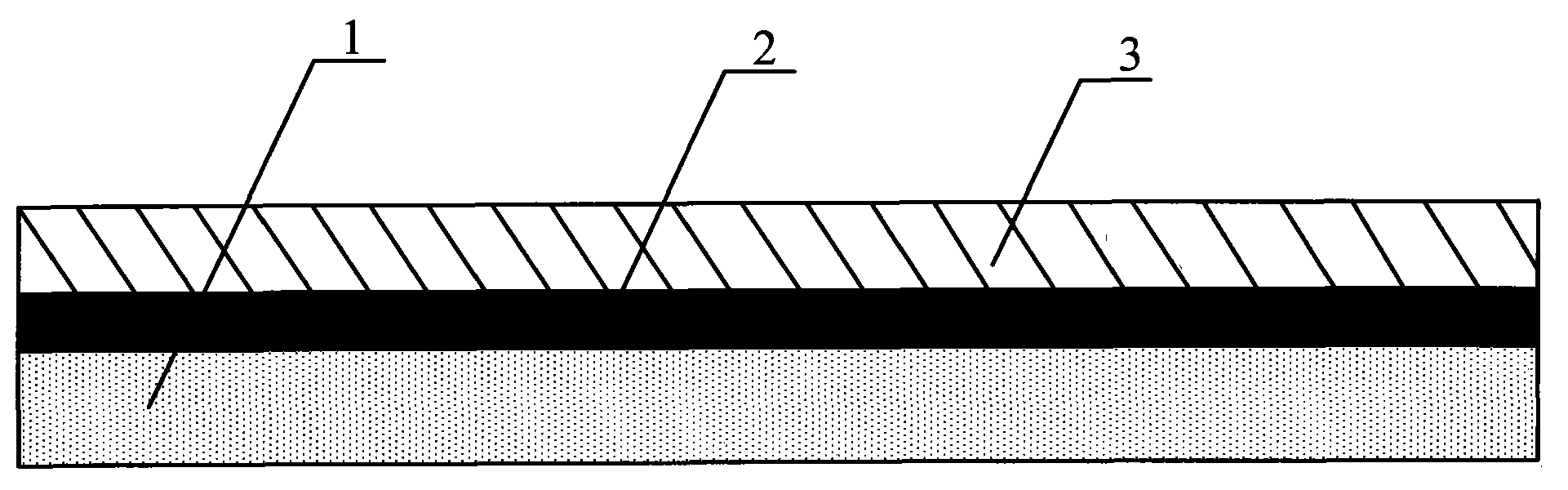

[0024] The steel pipe 1 of the present invention can be used to transport various liquids and gases. In order to ensure that the steel pipe 1 will not be corroded by acidic or alkaline substances, the outer surface of the steel pipe 1 is covered with polyolefin composite material or epoxy coating. Formed anti-corrosion layer 2. The anticorrosion layer 2 can be selected arbitrarily according to the needs of the actual situation, and the polyolefin composite anticorrosion layer is preferably used in the present invention.

[0025] In order to prevent the anti-corrosion layer 2 from being damaged during the crossing construction, the outer surface of the anti-corrosion layer 2 is covered with a wear-resistant protective layer 3 made of fiber reinforced material and epoxy glue. According to actual needs, the wear-resistant protective layer 3 can be bonded to the outer surface of the anti-corrosion layer 2 of the entire steel pipe 1, or only to a certain part thereof, so as to meet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com