Anchor rod construction method for preventing water running and sand jetting during drilling hole

A technology of anchor bolt construction and flowing water sandblasting, which is applied in the direction of foundation structure engineering, construction, sheet pile walls, etc., and can solve the problems of endangering the safety of structures and road pipelines, the danger of construction personnel and construction equipment, and the erosion of water and soil in oblique drilling. , to achieve good economic benefits, simple construction methods, and good blowout prevention effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

[0032] A bolt construction method for preventing drilling flow water blasting, comprising the following steps:

[0033] 1. Modulate anti-blowout packing

[0034] According to the requirements of bolt construction, prepare a certain amount of rapid solidification and strong cohesive blowout preventive filler. Blowout preventive fillers are generally rapid cements, and similar rapid setting materials.

[0036] Assemble the drill rod with the hole drill bit and place it next to the hole to be drilled.

[0037] 3. Initial drilling

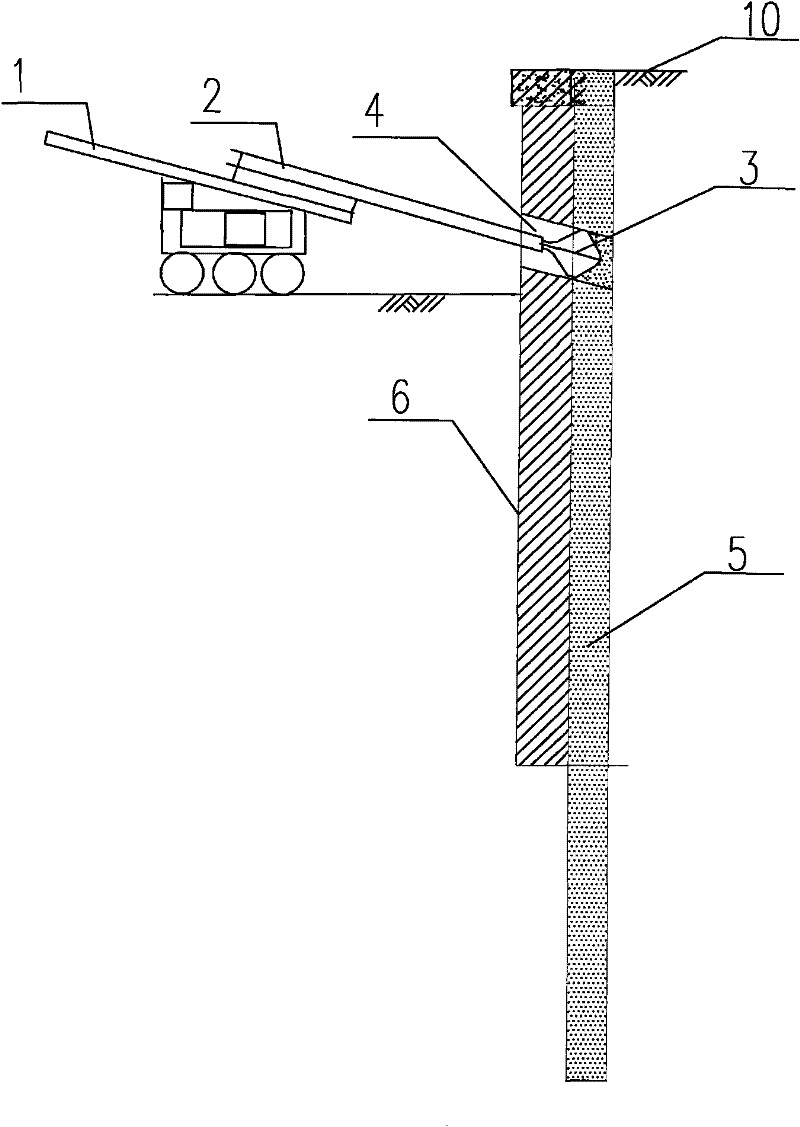

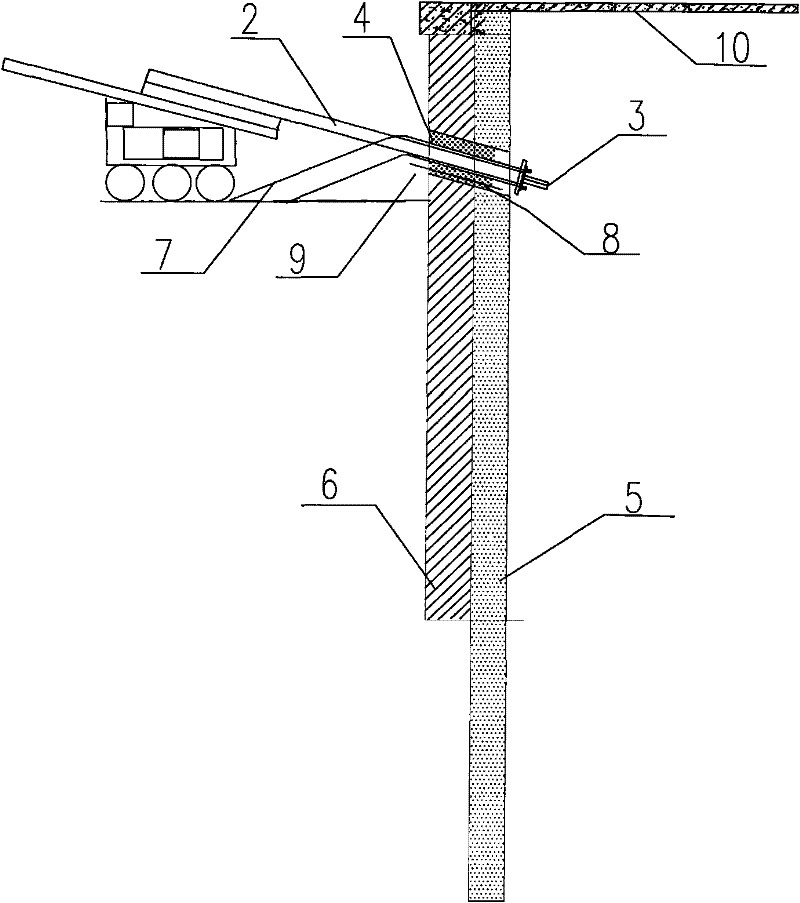

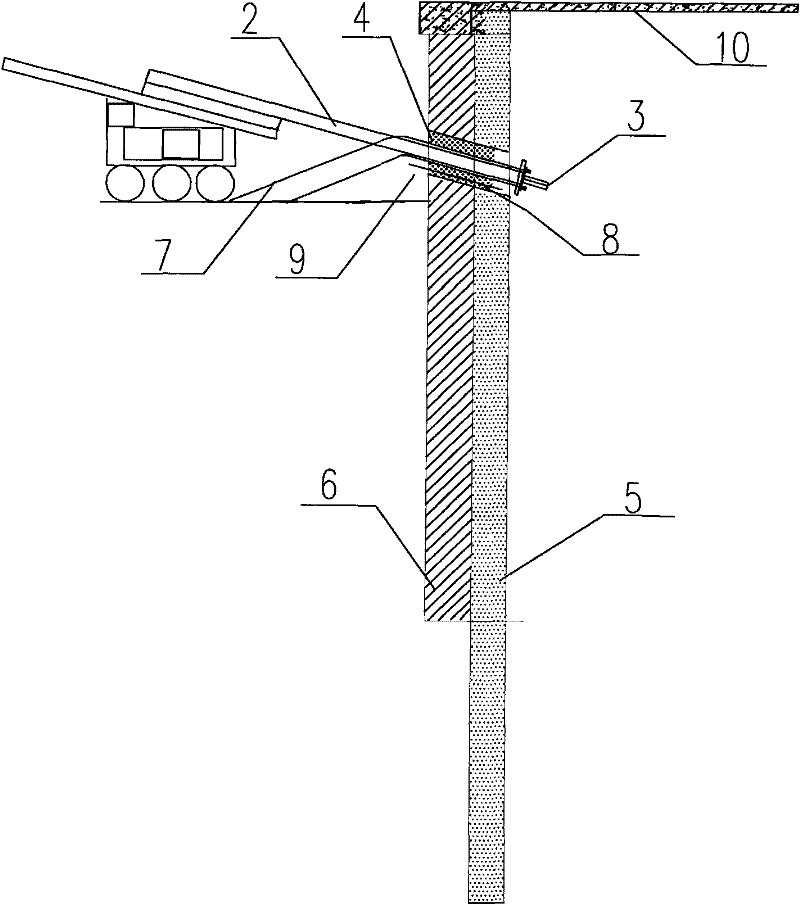

[0038] see figure 1 , use the drill bit 3 to drill holes at the corresponding position on the water-stop curtain 5 according to the design angle, and the hole is not drilled through the wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com