Method for hydrotreating heavy hydrocarbon

A technology for hydrotreating and heavy hydrocarbons, which is applied in the fields of hydrotreating process, hydrocarbon oil treatment, petroleum industry, etc., and can solve problems such as shutdown of residual oil hydrogenation unit, increase in temperature rise, and increase in pressure drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

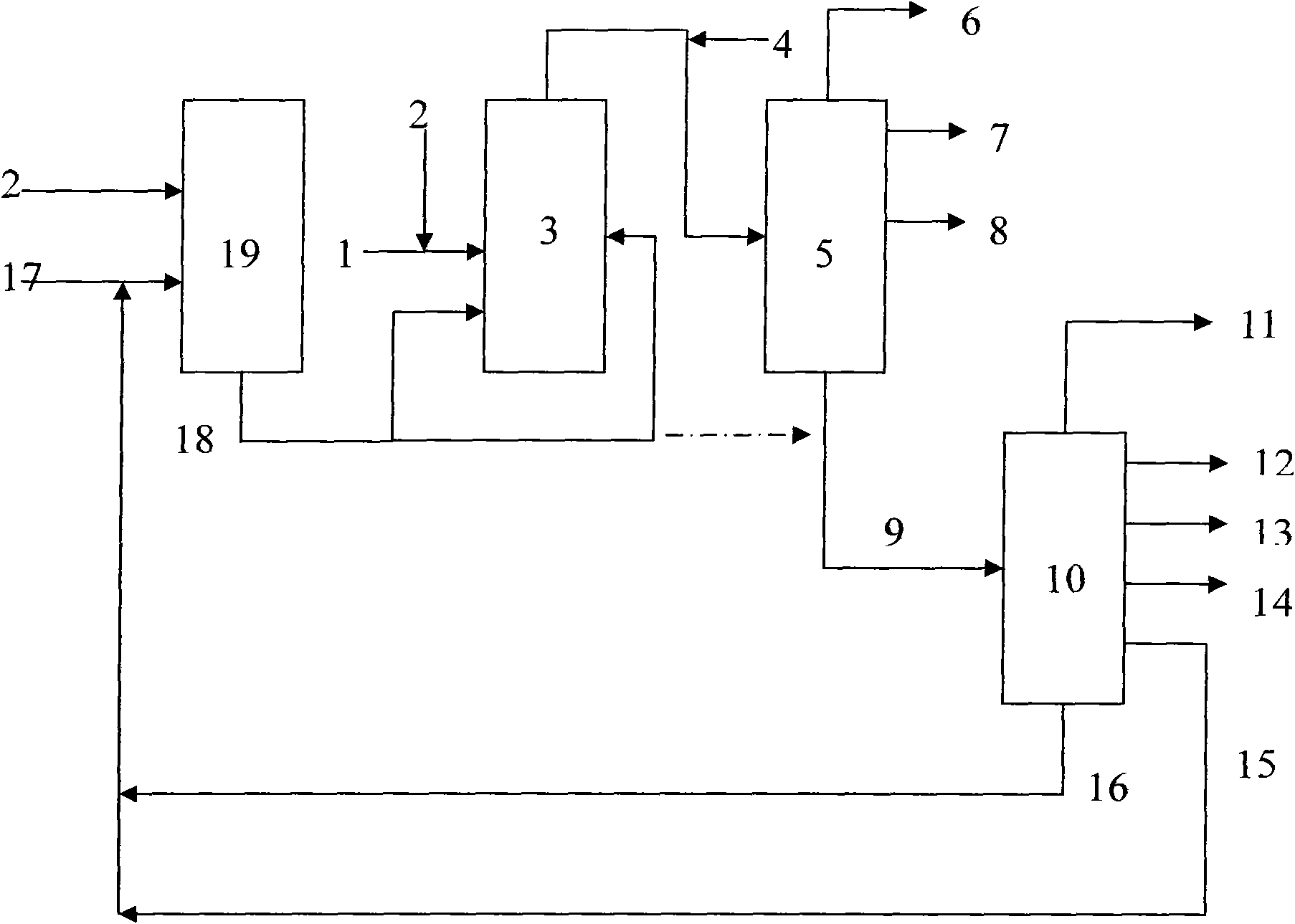

Method used

Image

Examples

Embodiment 1

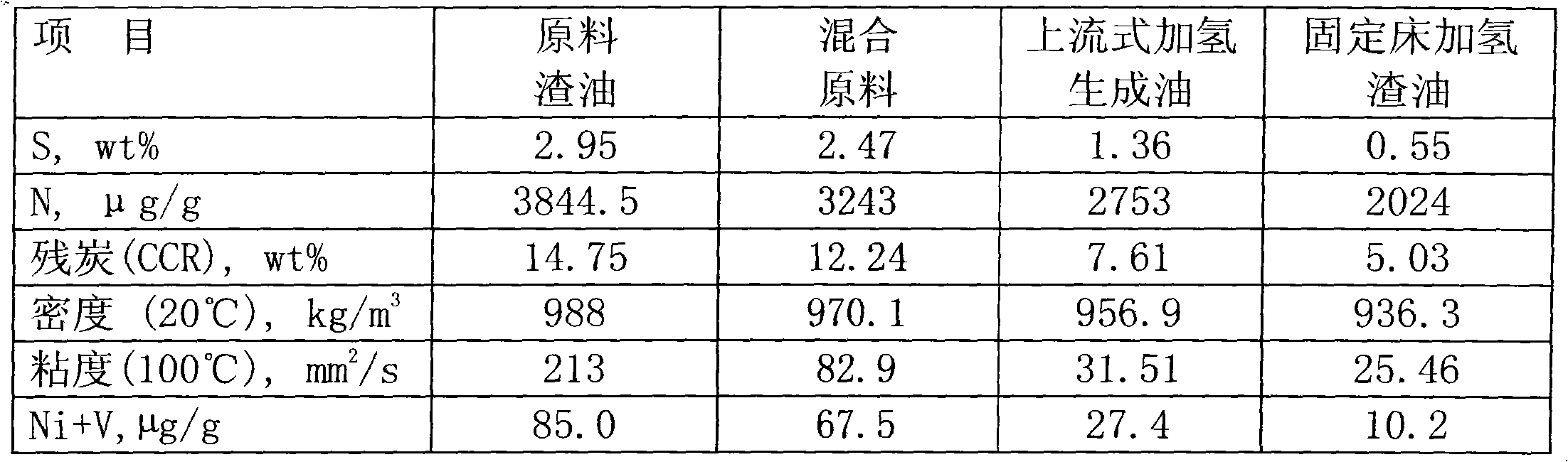

[0033] The pre-hydrogenation reaction was carried out in a small fixed-bed reactor, and the test was carried out on a small-scale riser catalytic cracking unit equipped with a pilot-scale upflow and fixed-bed residual oil hydrogenation unit.

[0034] prehydrogenation reaction

[0035] In the pre-hydrogenation reactor, the catalyst used in this test is the fixed-bed residue hydrogenation protection agent and demetallization catalyst produced by Sinopec Catalyst Company. Protective agents are CEN-2, CEN-4, FZC-16; demetallization catalysts are CEN-5, CEN-6. The loading ratio between the catalysts is:

[0036] CEN-2:FZC-16:CEN-4:CEN-5:CEN-6=1:1.25:1.25:5:1.5 (V / V).

[0037] The pre-hydrogenation raw material A used in this test is prepared by blending catalytic cracking oil slurry and circulating oil at a weight ratio of 2:8, and its properties are shown in Table 1. Take a certain amount of raw material A and mix it with hydrogen and enter it into the pre-hydrogenation reactor...

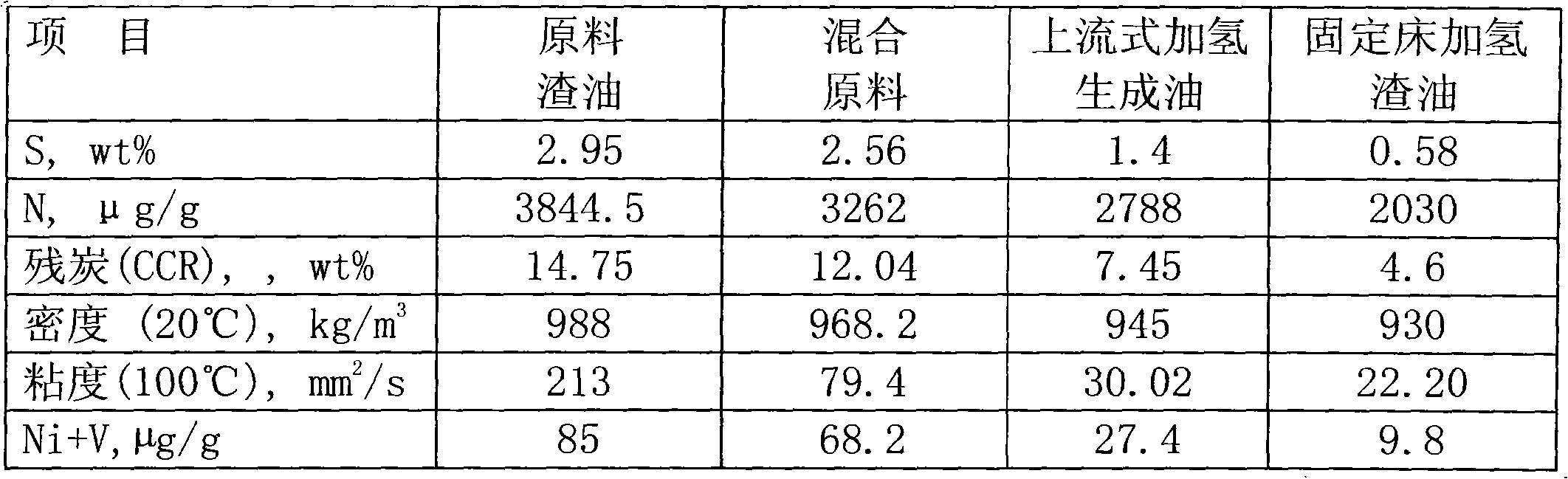

Embodiment 2

[0055] Using the same catalyst loading and test conditions as in Example 1, the pre-hydrogenation raw material is a mixed oil of catalytic cracking oil slurry, heavy cycle oil and coker wax oil in a weight ratio of 2:4:4, and its properties are shown in Table 6. The quality of the prehydrogenation raw material B is the same as in Example 1, and after being mixed with hydrogen, it enters the prehydrogenation reactor for reaction, and the reaction conditions are the same as in Example 1. The reaction temperature is 380°C, the total reaction pressure is 14.0MPa, and the volume space velocity: 1.0h -1 , hydrogen oil specific volume (V / V) 500. Impurities such as sulfur and nitrogen were removed, and hydrogenation saturation reaction was carried out to obtain hydrogenated refined oil B. The properties are shown in Table 7.

[0056] Table 6 Main Properties of Prehydrogenation Raw Material B

[0057] project

CCR, wt%

4.3

S, wt%

2.13

N, μg / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com