Microemulsion composite of polyethylene wax oxide

A technology of oxidized polyethylene wax and microemulsion, which is applied in textiles, papermaking, fiber treatment, etc., can solve the problems of poor acid resistance stability, microemulsion flocculation, increased dosage, etc., and achieve transparent appearance, good dispersion and stability, The effect of broad application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

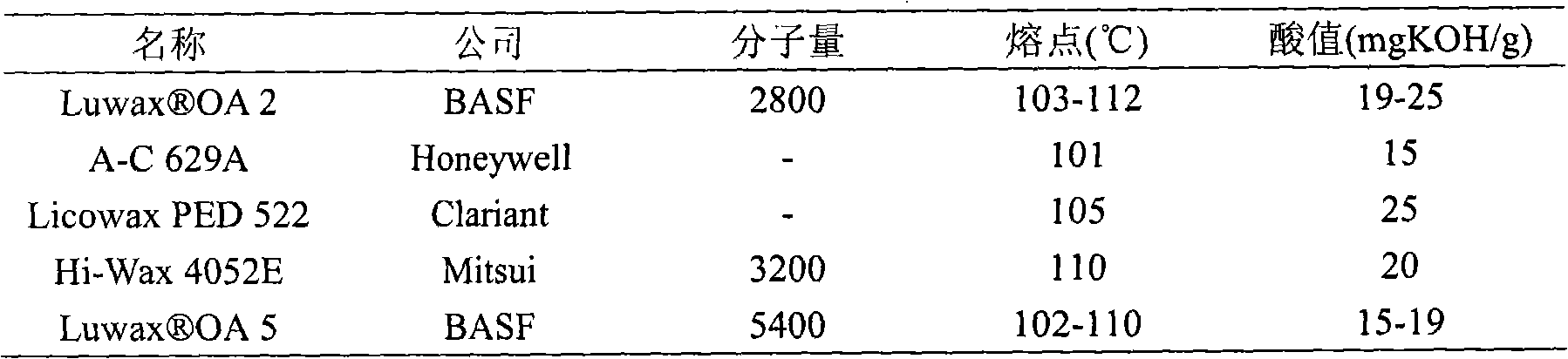

[0077] table 3

[0078] Emulsion formula:

[0079]

[0080] Emulsification method:

[0081] 2.500 kg OA 2. 0.374 kg of polyoxyethylene laureth (3EO), 0.826 kg of polyoxyethylene laureth (20EO), 0.1000 kg of dodecyl trimethyl ammonium chloride, 0.210 kg of lauric acid and 5.990 kg of water added to high temperature In the high-pressure emulsification kettle, the materials are heated to 115°C under high temperature and high pressure, keep a certain stirring to make the heat exchange fully, keep the temperature for 30 minutes, and cool down to 50°C for discharge.

Embodiment 2

[0083] Table 4

[0084] Emulsion formula:

[0085]

[0086] Emulsification method:

[0087] Combine 2.000 kg of AC 629A, 0.748 kg of dodecylamine polyoxyethylene ether (20EO), 0.423 kg of stearylamine polyoxyethylene ether (5EO) and 0.180 kg of cetyltrimethyl chloride Ammonium ammonium is added to the emulsification kettle, the materials are heated to 105°C at high temperature to melt them, the temperature of the materials is cooled to about 100°C, and 1 / 4 of 98°C hot water is slowly added to the emulsification kettle in about 30 minutes , And maintain high-speed stirring, add 1 / 3 of the 90℃ hot water into the emulsification kettle within 20 minutes, while maintaining high-speed stirring, quickly cool the material to 70℃, and add the remaining 5 / 12 of the cold water to the emulsifier The kettle, reduce the stirring speed, and discharge after cooling to 50°C.

Embodiment 3

[0089] table 5

[0090] Emulsion formula:

[0091]

[0092] Emulsification method:

[0093] 0.25 kg palmitic acid polyoxyethylene ether (5EO), 0.75 kg lauric acid polyoxyethylene ether (20EO), 0.05 kg dodecyltrimethylammonium chloride, 0.22 kg palmitic acid, 2.4 kg Licowax PED 522 and 6.33 Kg of water is added to the emulsification kettle, the materials are heated to 115°C under high temperature and high pressure, a certain amount of stirring is maintained for sufficient heat exchange, the temperature is kept for 30 minutes, and the temperature is lowered to 50°C for discharge.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com