Preparation method for ZSM-5 molecular sieve membrane with high hydrophobicity

A ZSM-5 and molecular sieve technology, which is applied in the field of preparation of high-performance hydrophobic ZSM-5 molecular sieve membranes, can solve problems such as molecular sieve membrane cracks and molecular sieve membrane separation performance degradation, and achieve reduced production costs and improved pervaporation separation performance , Highly complete effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] It is an existing technology to prepare a pure silicon ZSM-5 molecular sieve crystal layer on a macroporous carrier. The high-speed spin coating method and the low-speed pulling method of the prior art are respectively used to prepare a layer of tightly covered molecular sieve seed crystals on the macroporous carrier. layer. The specific preparation method is as follows: ① When coating the seed layer, molecular sieve particle colloid is used, the particle size is 400-500nm, the colloid concentration is 0.2-1.0wt.%, and an appropriate amount of PVA is added as a binder at the same time; The carrier coated with the seed layer was placed in a programmable muffle furnace and calcined in an air atmosphere to remove PVA and organic templates. The maximum calcining temperature was 450°C, and the heating and cooling rates were both 1°C / min. The calcined molecular sieve seed layer can be directly used in the subsequent hydrothermal synthesis, but calcining is not a necessary ste...

Embodiment 1

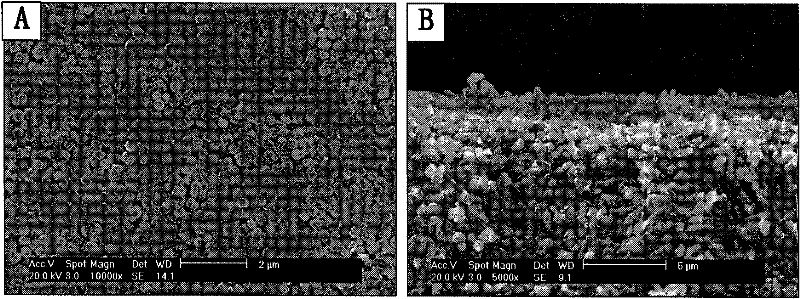

[0030] (1) Adopt the high-speed spin-coating method of prior art, first with deionized water, the suspension liquid of nano-sized molecular sieve small particles is diluted to 0.2~0.5wt% seed liquid, then the seed liquid is quickly added dropwise to α -Al 2 o 3 On the carrier, rotate at a high speed for 30 seconds, and finally dry in an oven at 60°C for 12 hours to obtain a denser molecular sieve seed layer. Such as figure 1 As shown in A, by spin-coating molecular sieve seed liquid, the α-Al 2 o 3 The surface of the carrier is tightly covered with a layer of seed layer with a thickness of about 1.5 μm ( figure 1 B).

[0031] (2) Preparation of pure silicon ZSM-5 molecular sieve membrane

[0032] According to 1TEOS: 0.2TPAOH: 850H 2 The molar ratio of O was used to configure the synthesis solution, and the alumina carrier coated with the seed crystal was placed in an autoclave with a Teflon liner, and the synthesis solution was poured into the alumina carrier to cover; ...

Embodiment 2

[0040] (1) Preparation of Fe-ZSM-5 molecular sieve seed layer on flake alumina carrier

[0041] Nanoscale Fe-ZSM-5 molecular sieve particles were used to configure the seed liquid, and the specific method was the same as that in Example 1. The molecular sieve seed layer was calcined at 450° C. for 8 hours, and then used for the subsequent secondary growth.

[0042] (2) Preparation of Fe-ZSM-5 molecular sieve membrane

[0043] According to 1TEOS: 0.2TPAOH: 0.005Fe(NO 3 ) 3 : 750H 2 The molar ratio of O configures the synthesis solution.

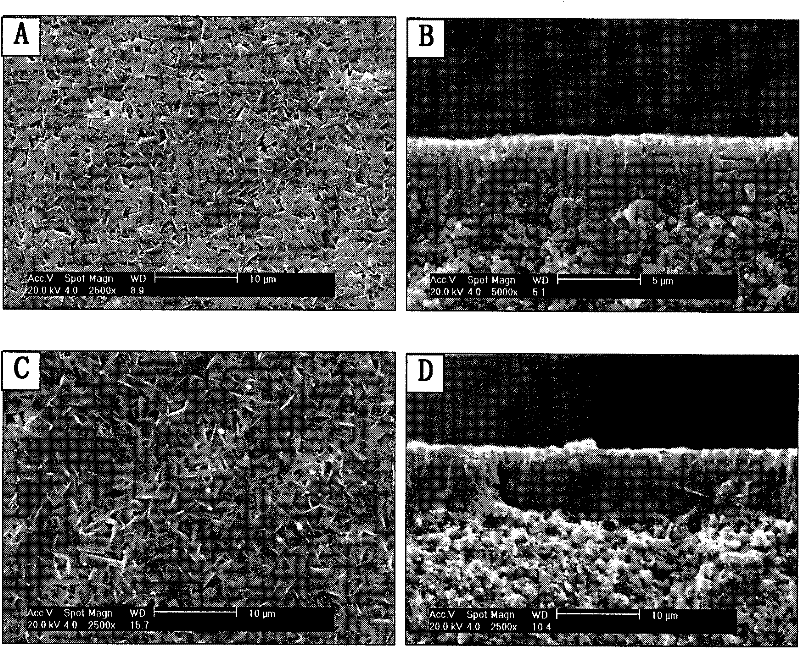

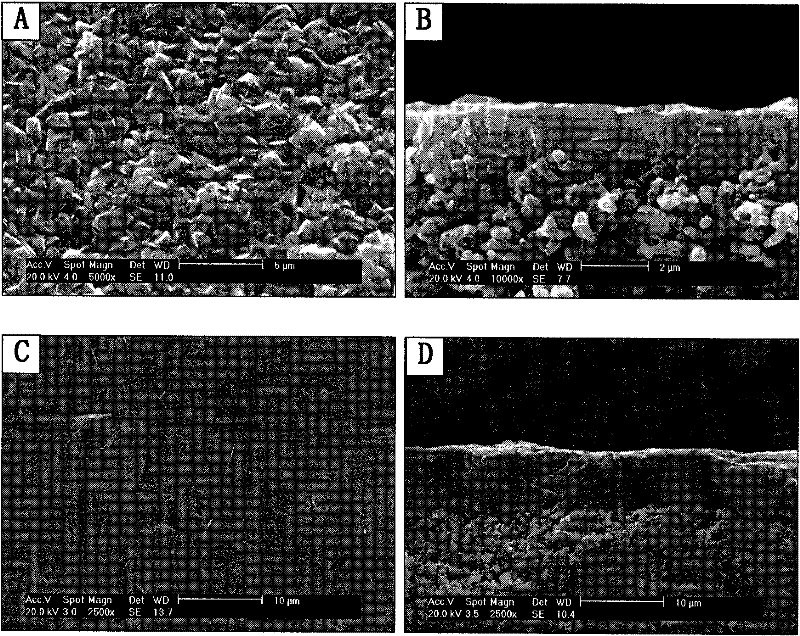

[0044] Containing Fe 3+ After hydrothermal crystallization at 150°C for 4 hours, the molecular sieve seeds are well cross-linked to form a hOh-oriented ZSM-5 molecular sieve film layer with a thickness of about 1.5 μm ( image 3 A&B). From the SEM photos, it can be seen that the ZSM-5 molecular sieve membrane after one synthesis has been fully cross-linked, and there is almost no growth in the direction perpendicular to the support (out...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com