Preparation method of mesopore molecular sieve containing beta zeolite secondary structural unit

A secondary structural unit, mesoporous molecular sieve technology, applied in the direction of crystalline aluminosilicate zeolite, etc., can solve the problems of high price of organic templates, narrow range of silicon-aluminum ratio, and complicated synthesis process, so as to save the synthesis process and save energy. The effect of large adjustment range, acidity and acidity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

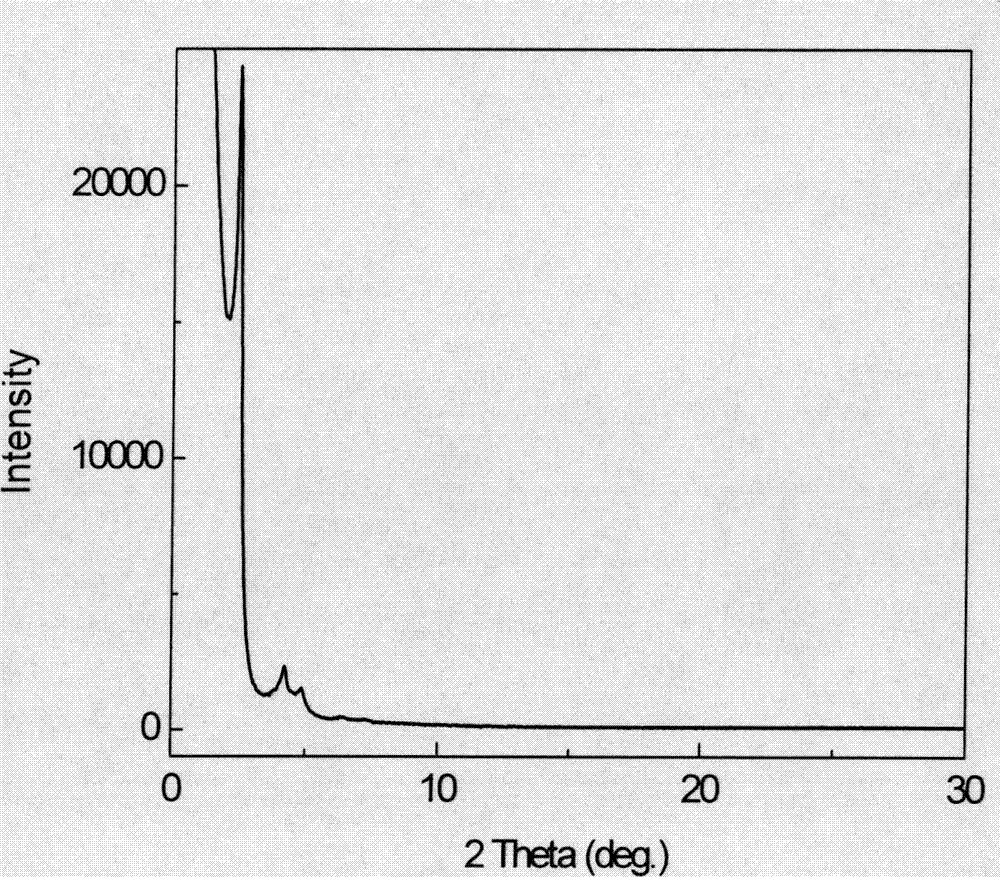

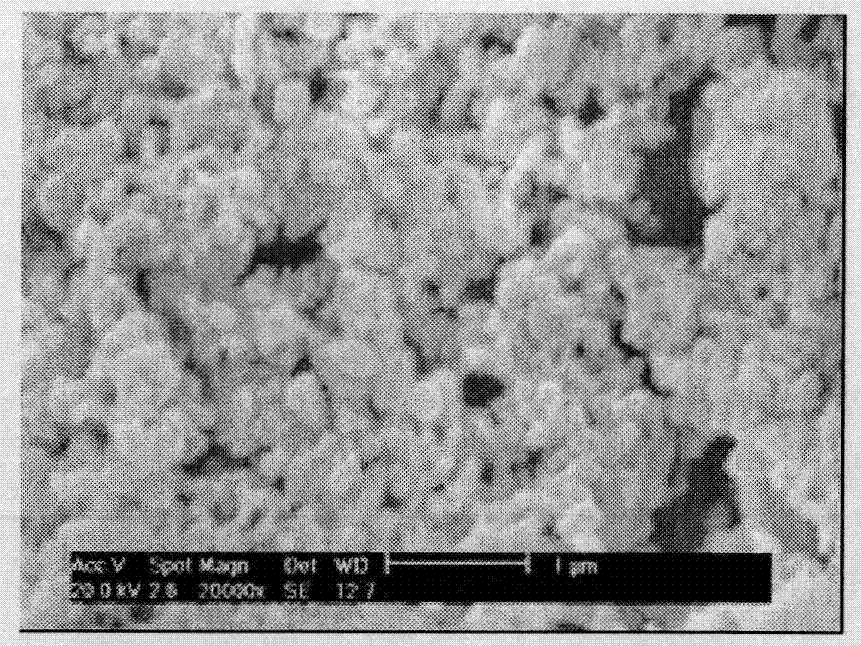

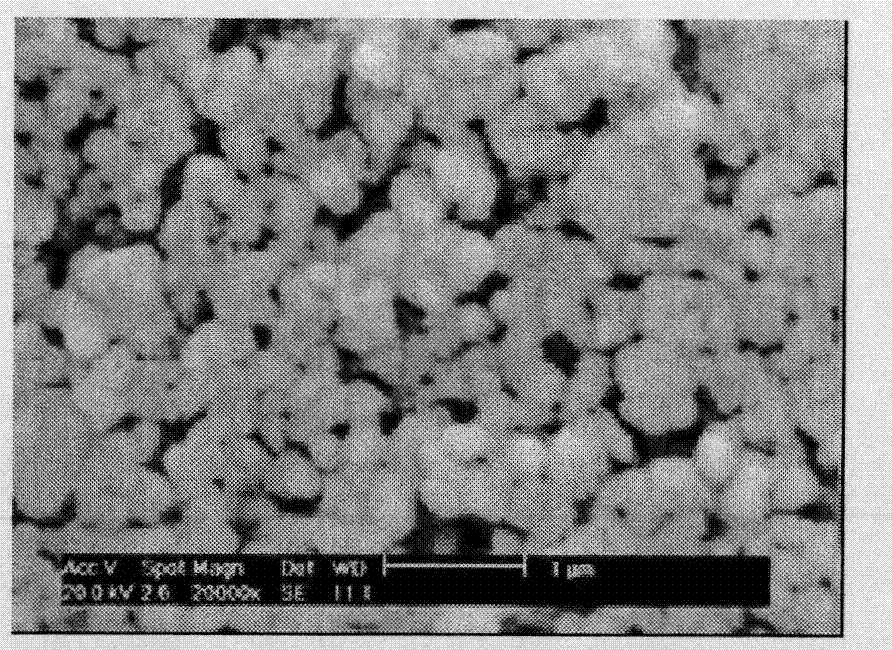

[0030] Industrially synthesized NaBeta(SiO 2 / Al 2 o 3 Molecular molar ratio is 25, the following are all SiO 2 / Al 2 o 3 Both are molecular molar ratios) 5.2g of zeolite is dispersed in 200mL 4M HCl solution to form a hydrogel. After stirring at room temperature for 1h, put it into a synthesis kettle, place it at 120°C for 6h, and adjust the pH value to 13 with 6M NaOH after cooling. About; then drop 12.5g of 16wt% cetyltrimethylammonium chloride solution into the hydrogel, stir at 50°C for 40min, and adjust the pH to about 10 with hydrochloric acid; stir evenly and put the material into the lining polytetrafluoroethylene crystallized at 110°C for 4 days; then filtered, washed, and dried at 100°C for 24 hours; and then calcined at 550°C for 8 hours in an air atmosphere to obtain the desired product. The molecular sieve sample whose crystal phase is MCM-41 was obtained by XRD analysis. According to infrared spectrum (IR) analysis, the framework of the MCM-41 product cont...

Embodiment 2

[0032] Industrially synthesized NaBeta(SiO 2 / Al 2 o 3 Molecular molar ratio is 25, the following are all SiO 2 / Al 2 o 3 Both are molecular molar ratio) Zeolite 5.2g is dispersed in 200mL 4M H 2 SO 4In the solution, a hydrogel is formed. After stirring at room temperature for 1 hour, put it into a synthesis kettle, place it at 100°C for 12 hours, and adjust the pH value to about 13 with 6M NaOH after cooling; Drop ammonium chloride solution into the hydrogel, stir at 50°C for 40 minutes, then add 7g of tetraethyl orthosilicate, and hydrochloric acid to adjust the pH to about 10; Crystallize at 130°C for 3 days; then filter, wash, and dry at 100°C for 24 hours; then bake at 550°C for 8 hours in an air atmosphere to obtain the desired product. The molecular sieve sample whose crystal phase is MCM-41 was obtained by XRD analysis. According to infrared spectrum (IR) analysis, the framework of the MCM-41 product contains Beta zeolite secondary structural units.

Embodiment 3

[0034] Industrially synthesized NaBeta zeolite, SiO 2 / Al 2 o 3 =50, 4.2g dispersed in 300mL 0.5MHNO 3 In the solution, a hydrogel is formed, stirred at room temperature for 1h, put into a synthesis kettle, placed at 150°C for 3h, and adjusted to pH 13 with 6M NaOH; then 12.0g 16wt% cetyltrimethylammonium bromide Drop the solution into the hydrogel, stir at 50°C for 40min, and adjust the pH to about 10 with hydrochloric acid; after stirring evenly, put it into a crystallization kettle lined with polytetrafluoroethylene, and crystallize at 110°C for 3 days; then filter, wash, and dry at 100°C Dry at ℃ for 24h; then bake at 550℃ in air atmosphere for 8h to obtain the target product. The molecular sieve sample whose crystal phase is MCM-41 was obtained by XRD analysis. According to infrared spectrum (IR) analysis, the framework of the MCM-41 product contains Beta zeolite secondary structural units.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com