Twin surface grinder

A double-face grinding machine and grinding technology, which is applied to grinding machines, parts of grinding machine tools, and machine tools suitable for grinding workpiece planes, etc. It can solve the problems of low feed resolution, unstable hydraulic pressure, and high temperature requirements. Achieve the effects of high feed resolution, intuitive display, and precise motion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

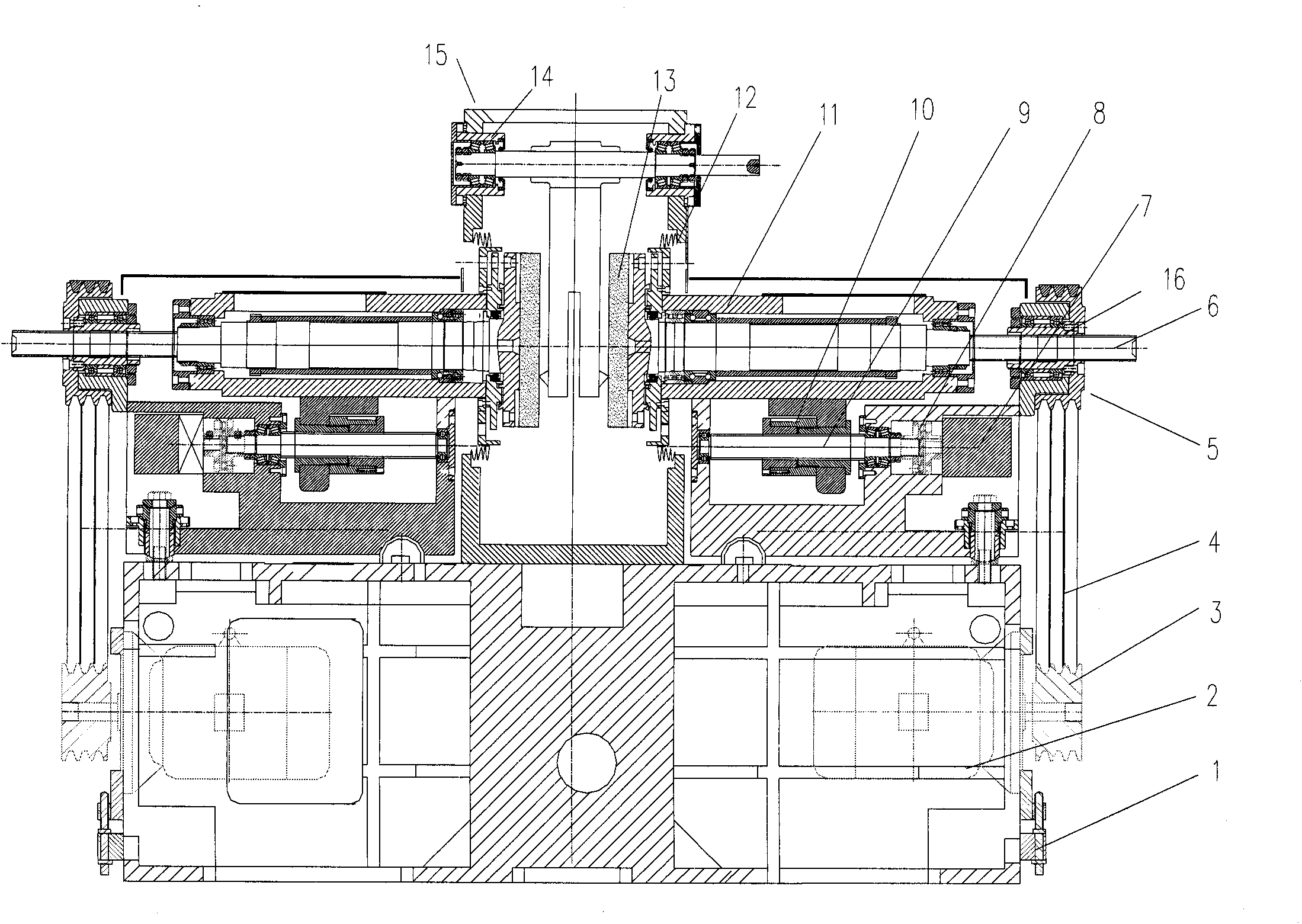

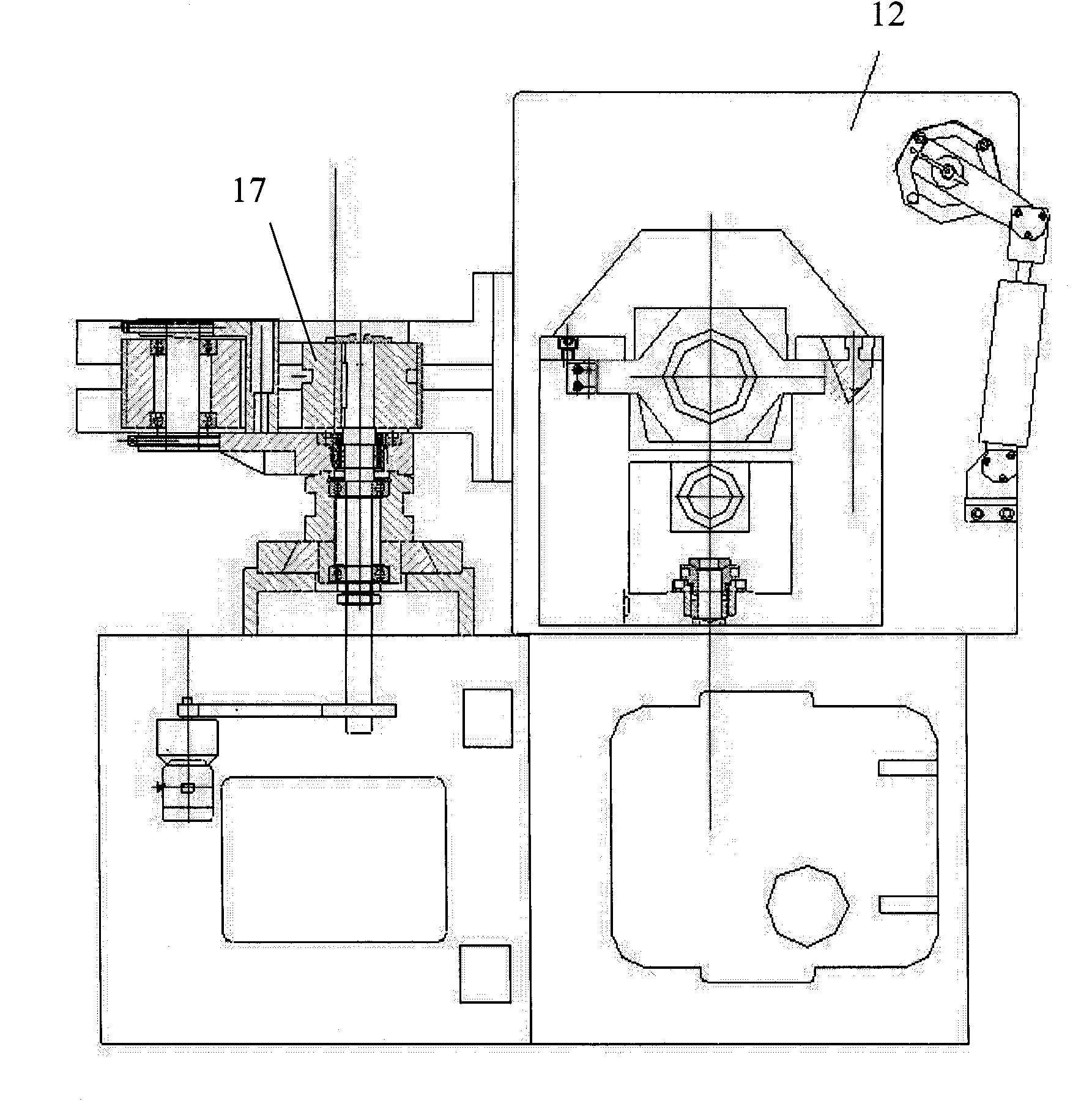

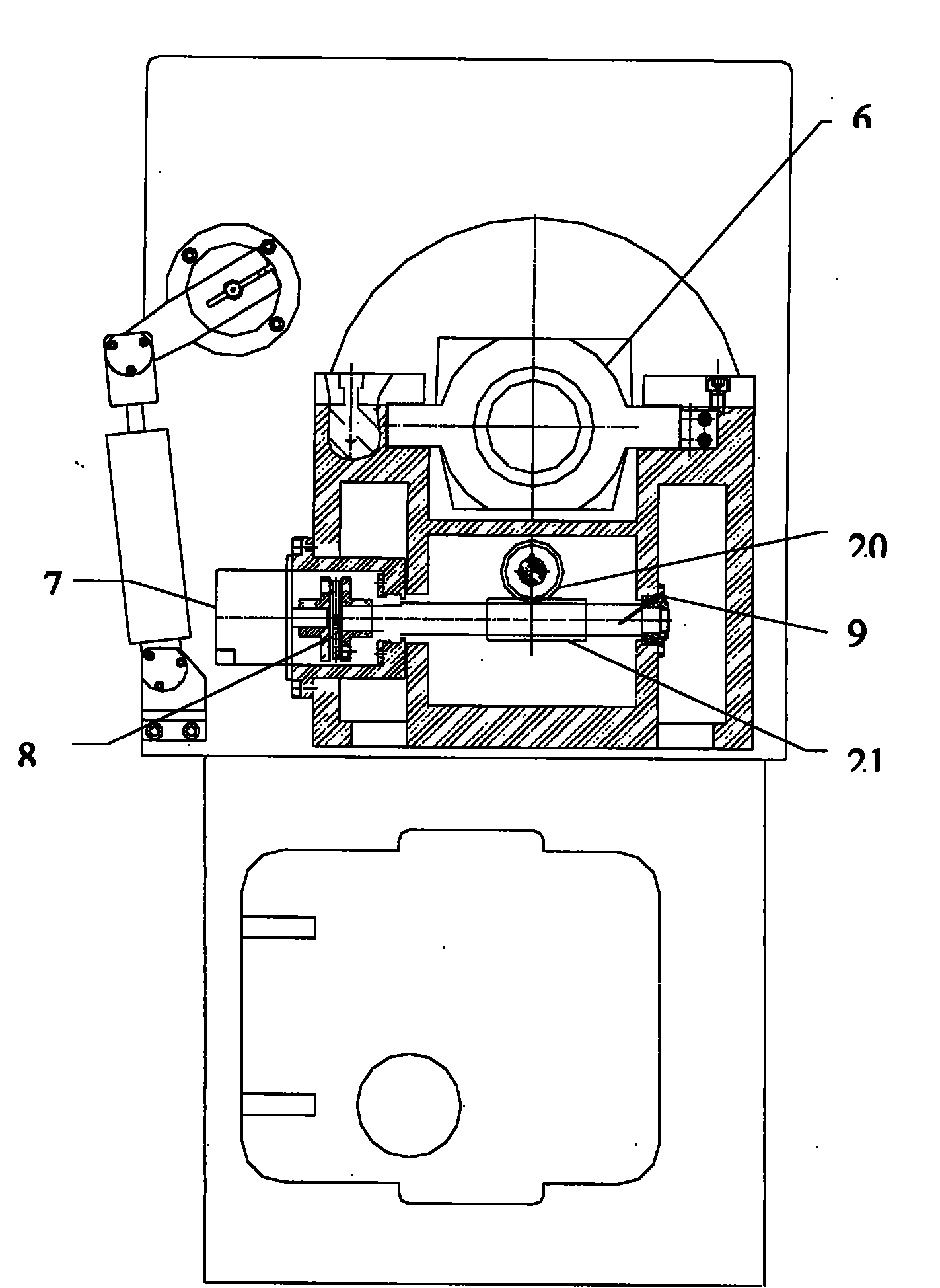

[0020] An embodiment of the present invention provides a double-end grinding machine. It includes a bed, a main shaft on the bed, a main shaft assembly, a grinding wheel dresser assembly, a grinding wheel, a main shaft motor, a motor unit, and a lead screw. The grinding wheel is installed at one end of the main shaft, and the grinding wheel dresser assembly is installed on the grinding wheel. The main shaft assembly is installed on the main shaft, one end of the lead screw is connected to the motor unit, and the lead screw is connected to the main shaft assembly, the motor unit controls the rotation of the lead screw, and the lead screw drives the main shaft assembly to move left and right, thereby realizing Feed motion during the grinding process, the spindle motor is used to drive the grinding wheel and the spindle to rotate, so as to realize the grinding motion.

[0021] In order to make the technical solution of the present invention clearer, the present invention will be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com