Small-sized portable air brazing welding gun

A portable, brazing welding technology, applied in welding equipment, electric heating equipment, metal processing equipment, etc., can solve the problems of no gas pressure adjustment device, failure to meet user requirements, no automatic ignition device, etc., to eliminate fear, weight, etc. Lightweight and easy to carry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

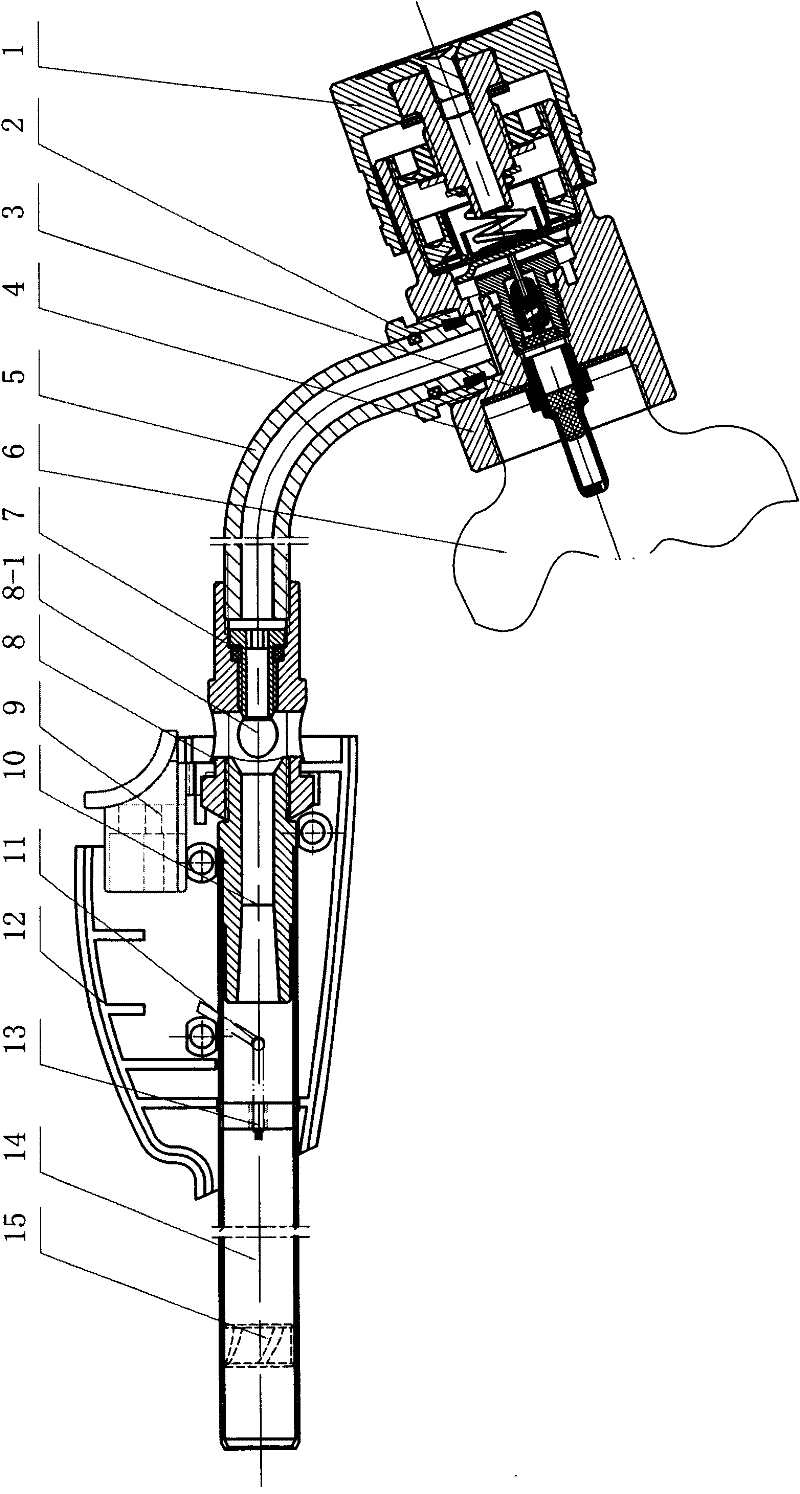

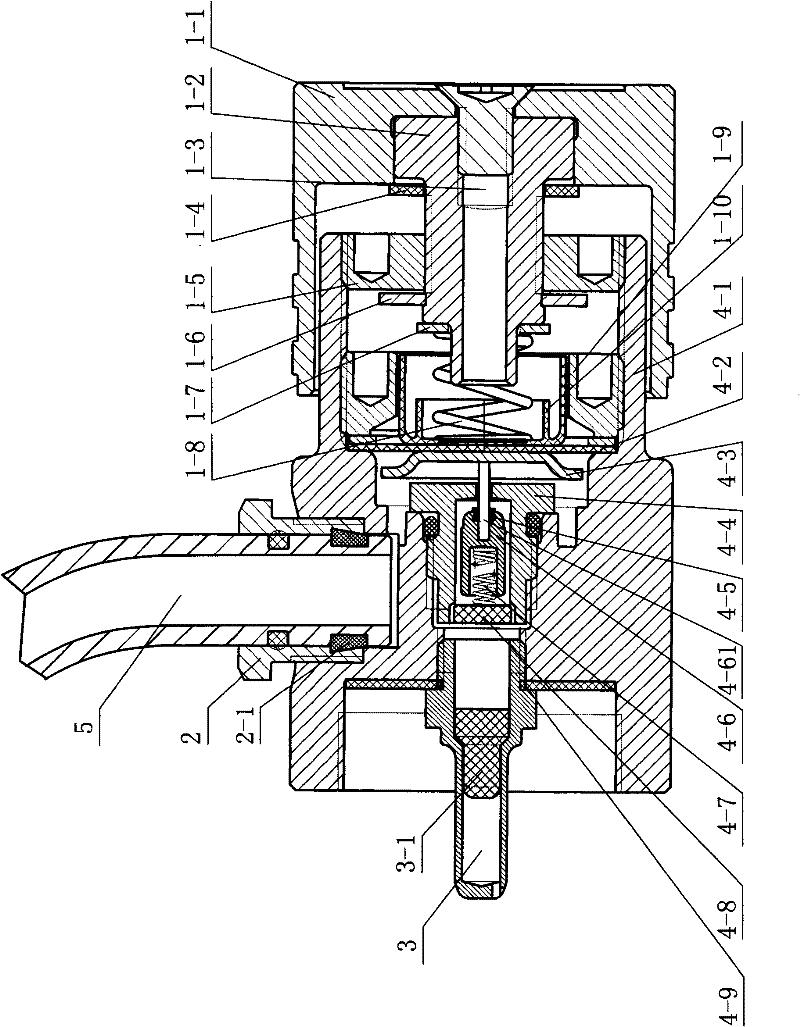

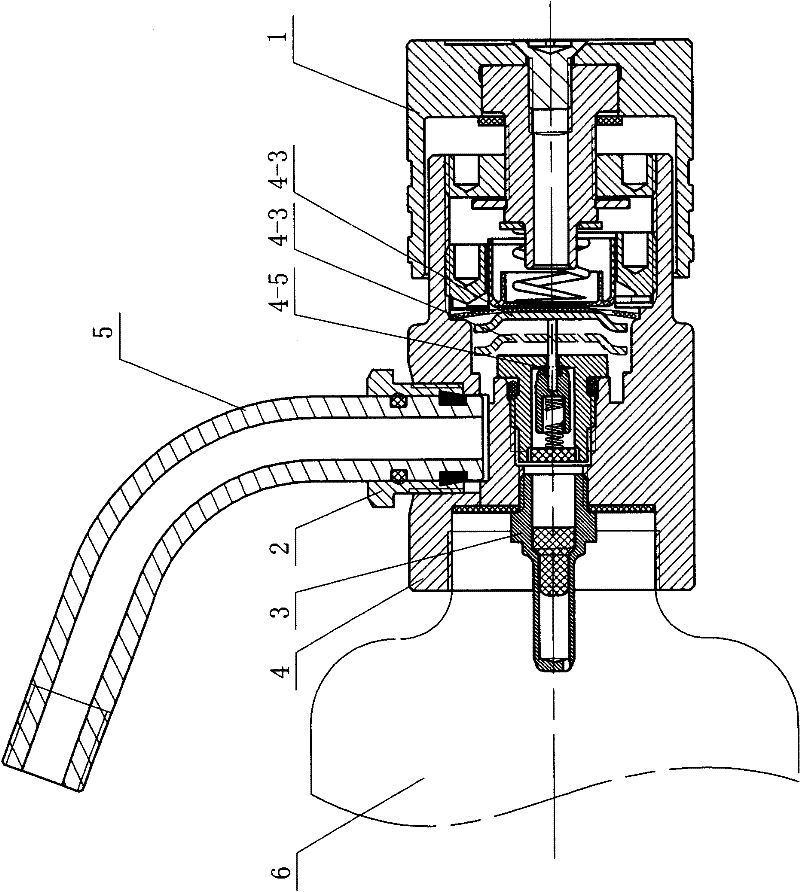

[0014] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0015] There are four evenly distributed through holes with a chamfer of 120° on the middle periphery of the air mixer 8. The diameter of the through holes is Φ5 ~ Φ6mm and communicates with the outside. The through hole is the air inlet 8-1. Enter to mix with gas.

[0016] The air mixer 8 has a through hole in the middle of the axial direction, an opening at one end, and a nozzle 7 with a spray hole on the bottom surface of the other end, which is packed into a stepped hole at one end of the air mixer 8 with a sealing ring.

[0017] There is through hole in the middle, and through hole at both ends is the nozzle pipe 10 that trumpet is convenient to air and gas inlet and outlet, utilizes the external screw thread on it and an end of gun barrel 14 and air mixer 8 to fix respectively.

[0018] The ignition wire 11 of the igniter 9 is installed on the ign...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com