Piston rod finish-rolling device and processing process thereof

A processing technology and piston rod technology, applied in the direction of metal rolling, etc., can solve the problems of easy appearance of patterns on the surface of the piston rod, excessive wear and tear of the grinding wheel, high production cost, etc., and achieve high surface roughness and precision, shorten the production cycle and reduce the production cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

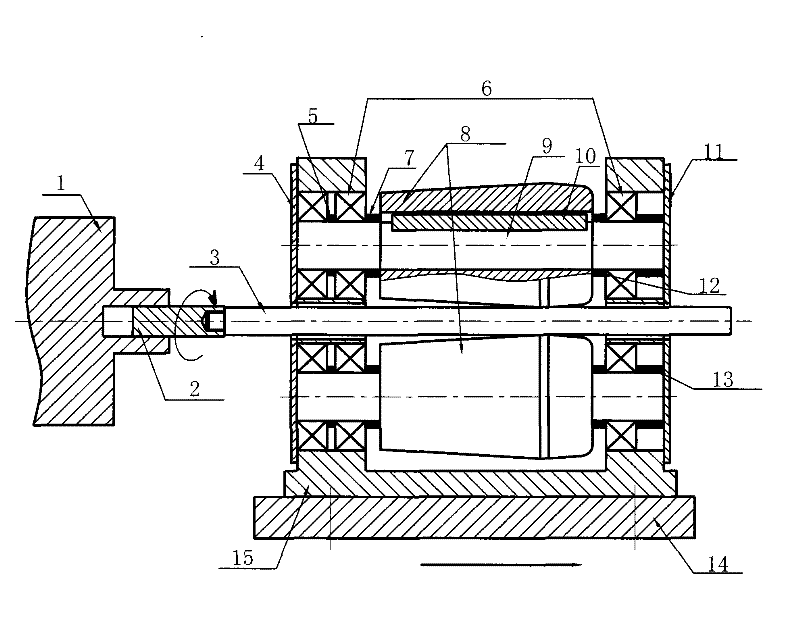

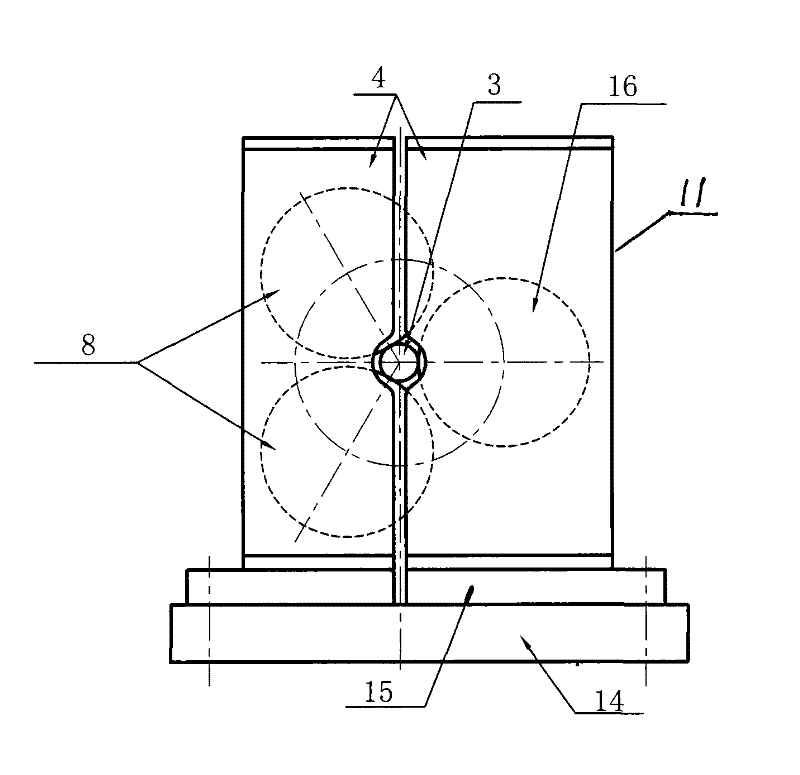

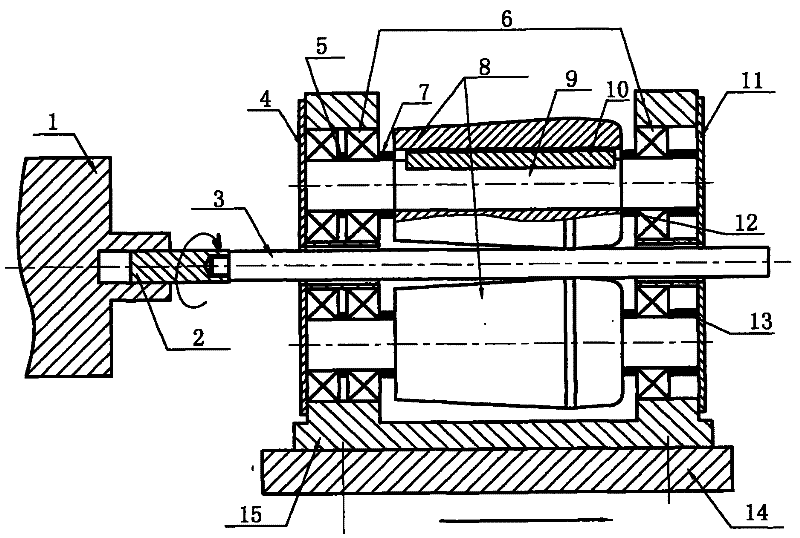

[0011] Such as figure 1 , 2 As shown, the finish rolling device mainly has two fixed rollers 8 . Wherein the adjustment roller 16 forms an assembly with three roller shafts 9 and keys 10 respectively, and then is packed into the frame 15 bearing holes respectively, and the three rollers are distributed at 120°; Circle 5 and be provided with three rollers and frame 15 to keep the front spacer ring 7 of clearance, rear spacer ring 12, rear bearing spacer ring 13 is installed on the slide plate 14 that can longitudinally move after the above parts are assembled. The processing technology of the piston rod is: machining - rough grinding before rolling - fine grinding before rolling - finishing rolling - electroplating - polishing. The finishing rolling process is as follows: ① install the three-roller finishing rolling device on a machine tool with a rotating power head 1 (including guide rails, slide plates 14 and slide boxes); The size of the outer diameter of the rod is the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com