Light emitting diode driving method

A technology of light-emitting diodes and driving methods, which is applied in the direction of instruments and static indicators, etc., can solve the problems of concentrated current consumption, low luminous efficiency of light-emitting diodes, energy loss and temperature rise, etc., to reduce energy consumption and uniform current Consumption and reduce the effect of transvoltage loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

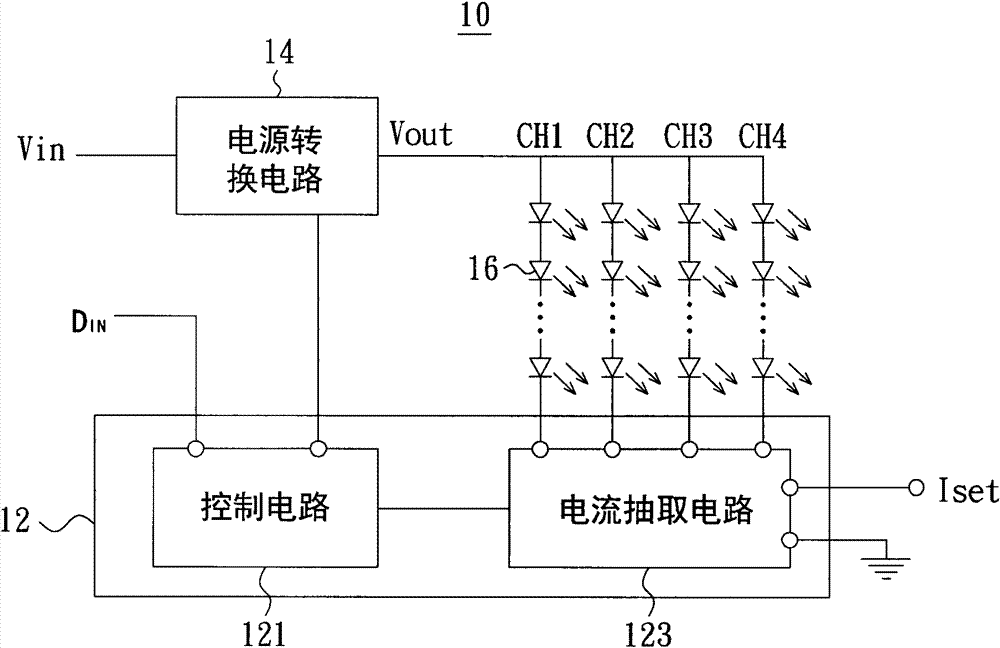

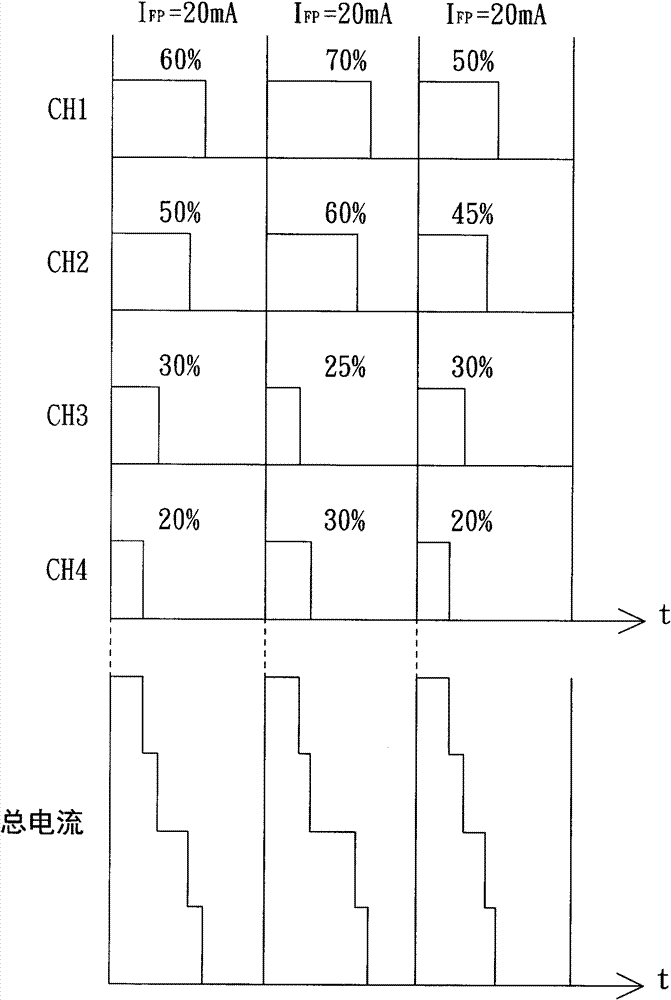

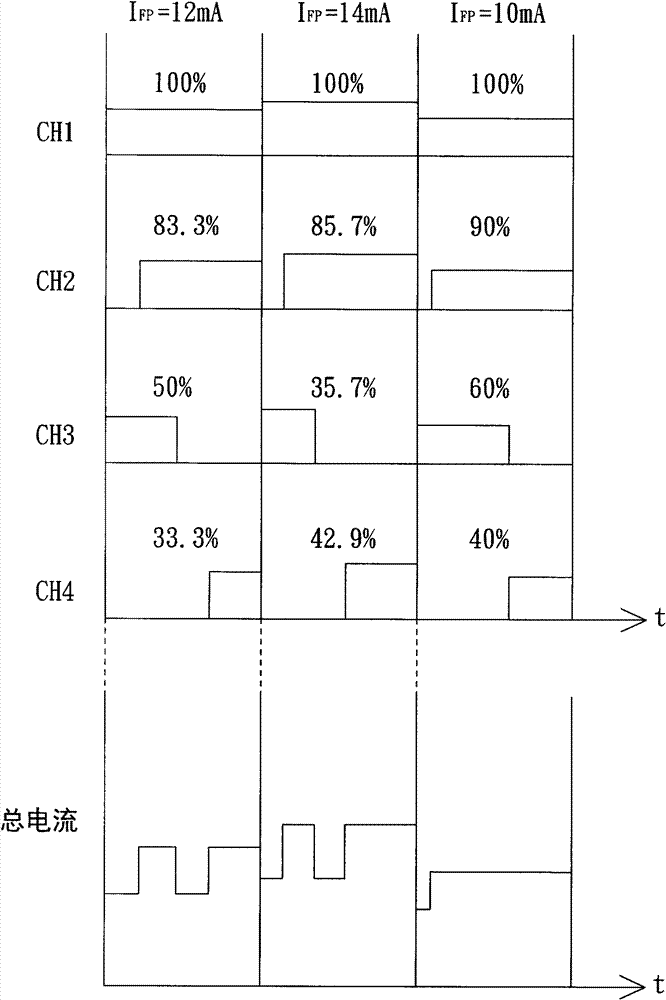

[0028] see image 3 , which shows a schematic diagram of the state of the driving current of each LED string when performing local dimming in an LED driving method related to an embodiment of the present invention. Here, it should be noted that the light emitting diode driving method in the embodiment of the present invention can also be implemented in figure 1 For the LED backlight module shown, the designer only needs to increase figure 1 The functions of the control circuit 121 and the current extraction circuit 123 are enough, so that the control circuit 121 has the function of adjusting the duty cycle of the driving current of each LED string such as CH1~CH4 within the frequency cycle, and the current extraction circuit 123 has the function of adjusting The current value of the driving current of each LED string CH1-CH4 within the frequency period.

[0029] The following will combine figure 2 and image 3 The method for driving a light emitting diode according to an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com